Baoshan Craftsman Star | Artist, skillful — remember "Shanghai Craftsman" Zhu Zhenyuan

Author:Shanghai Baoshan Time:2022.07.03

During the lunch break, Zhu Zhenyuan received a call from the plum worker from Zhanjiang No. 1 sintering machine project team. "The hydraulic micro gate has a fault, and the production has been suspended for more than ten hours. It has not been found for the reason." Mei Workers' tone is anxious: "The company has a hard instruction, and production must be resumed before 3 pm. I can find you. "Zhu Zhenyuan asked the situation briefly, and he basically knew it. He said to Mei Gong, "Don't worry, I come here immediately."

Sinterns are a key process for steel smelting. The problem of the hydraulic micro gate means that it cannot be uniformly favored, and the sintering machine can only stop running, which will affect the entire smelting project. Zhanjiang sintering machine No. 1 is a Baosteel Group. It is one of the most advanced large -scale sintering machines in China. It has been suspended for one day and loses huge losses.

Zhu Zhenyuan quickly arrived at the scene. From the project commander to the on -site engineer, everyone is anxious to turn. Zhu Zhenyuan learned that when there was no device action, the PLC communication was normal, but as the device moved, the UPS power supply voltage decreased instantly, the communication was disconnected, and the devices stopped. After comprehensive consideration, Zhu Zhenyuan boldly judged that there should be a slight leakage and short circuit in a certain part of the system. In the urgent eyes of everyone, Zhu Zhenyuan adopted the exclusion method to eliminate the possible fault one by one, decisively cut the special cable of the position sensor, and found the fault position. At first glance, it turned out that the fire was not controlled during production, and the cable was baked to cause cable adhesion. Under normal circumstances, this failure is extremely difficult to find. Zhu Zhenyuan quickly replaced the components and cables, the test machine again, the equipment started normally, and the scene was jubilant. At this moment, Zhu Zhenyuan arrived at the scene, but more than half an hour.

Zhu Zhenyuan is 52 years old, medium, thin and upright. At work, he will always wear a blue work suit and walk like wind. Zhu Zhenyuan worked at China Twenty Metallurgical Group Shanghai Twenty Metallurgical Construction Co., Ltd. Installation Engineering Branch, and was the leader of "Zhu Zhen's original Innovation Studio". Entering the studio, the honor and the awarding status occupied a wall -"National Technical Expert", "Central Enterprise Technology Expert", "China Metallurgical Group Advanced Workers", "Shanghai Construction of Excellent Talent Talent Characters", "National Metallurgy Construction Industry Advanced Skills "Experts", "Shanghai Craftsman", "Shanghai May Day Labor Medal" ... Open Zhu Zhenyuan's toolbox, different types of wrenches, screwdrivers, round mouth pliers, pointed clamps, piping clamps, threading clamps ... Essence Open another layer, which is an electric pen, a multimeter, a signal generator, a communication protocol, an electric hand drill. Each tool and every instrument go through a hundred battles. In addition, Zhu Zhenyuan also has a specially prepared toolkit, which is specially used when traveling for facilitation to work at any time.

Back to 1993, the young man Zhu Zhenyuan successfully passed the refrigeration advanced work test and opened a cooling repair shop. He has good skills and enthusiasm, and the business of repairing shop has always been good. His father was an electrician at the China Metallurgy Group (China Metallurgical Science and Technology Group Co., Ltd.). At that time, a child replaced the system. The expectation of his father was Zhu Zhenyuan to pick up his class. After all, in that era, the "iron rice bowl" of state -owned enterprises was fragrant. Zhu Zhenyuan said that he didn't want to go to the factory to work in the factory. He would like to open a shop by himself. In the end, he still couldn't stubborn his father, turned off the repair shop, and became an electrical maintenance worker. The main task was to repair motors, welders, transformers and various electric tools. Divided into the mountains, Zhu Zhenyuan devoted all his enthusiasm to new work. In addition to seriously operating practice, he asked the master with an open mind. He bought many professional books and studied it as soon as he had time. Diligence was rewarded, stipulating that the apprenticeship period of three years, Zhu Zhenyuan changed to righteousness in just one year, and was promoted to the team leader. The motor winding mold that he improved can be applied to a variety of specifications of motors, which greatly saves costs and improves production efficiency.

Zhu Zhenyuan said that since he chose this road, he rushed towards this direction. He won't say anything, and he is willing to do something really. There are many types of electrical equipment, and the technical iterations are changing with each passing day. Zhu Zhenyuan believes that an excellent electrical worker should always maintain a strong curiosity and curiosity like a sponge absorbing water. Within a few months, do not contact the front line, without consulting the latest documents, knowledge will be out of place. On the other hand, no matter how new equipment is introduced, the basic electrical principles and logic will not change. To understand the essence of it, you can do it. The so -called one -li Lingli Liming is probably that.

During the construction of the Baosteel Silicon Steel project, the network was unstable, so that it could not communicate normally, which seriously affected the construction progress. Foreign engineers believe that this is caused by network cable connection. We have repeatedly required us to check the network cable, but it has not been able to solve the problem. Zhu Zhenyuan carefully checked the scene and judged that it was caused by the configuration of the card in the site. Through communication and inspection with foreign engineers and re -modifying the configuration, the network has returned to normal. The on -site intelligent execution agencies responsible for debugging were unable to move normally. After inspection, Zhu Zhenyuan found that the debugging method of the foreign party was wrong. He demonstrated the correct method to foreign personnel to ensure the normal advancement of the project.

During the construction of Wuxi Xuelang Steel Factory, during an inspection, Zhu Zhenyuan found that there was a problem with the control principle of an electric isolation knife, and the equipment was changed at the moment. The adjusted isolation knife can not only achieve the predetermined function, but also better guarantee safety. The equipment was imported from Italy. As soon as Italian experts came, you said that you were wrong. As a result, he dismantled everything and changed it back. Experts have been tapping for two days, and there have been various problems. No way, the expert had to find Zhu Zhenyuan, shrugged, or you came. Zhu Zhenyuan took the shot, and after a while, the equipment was running normally. Afterwards, Italian experts who originally raised eyebrows and vertical noses were orally by the "Signor Zhu". As long as Zhu Zhenyuan was recognized, it would be fine. In the past thirty years, Zhu Zhenyuan is proficient in electrical and instrument debugging in different construction fields such as metallurgy, chemical industry, electricity, and environmental protection. The work content covers the entire process of metallurgy. Every time a new site, he will be familiar with the construction tasks in advance, and the first time the drawing, component manual, and equipment schematic diagram will be turned out. As the person in charge of the debugging team, Zhu Zhenyuan came to the scene as much as possible. It stands to reason that debugging is the latter process, and the debuggers can intervene after the electrical installation is over. Zhu Zhenyuan believes that the process is intertwined. Only by cooperating with the upper and lower work processes can there be good results. He always cooperates with the electrical installation team and deployed in advance to facilitate the installation of electrical installation. He also avoids rework and improves efficiency.

Once the work starts, Zhu Zhenyuan always arrives at the construction site every day. Whether it is the two kilometers of the sintering engineering party, or the casting machine to transform the "snail shell" and complex environment; whether it is a thirty -meter -high pagoda or a six -meter -deep valve station, he has to take one by himself one by one In the circle, the construction progress is made, and then reasonably arrange the debugging task of a new day. The reconstruction project of Baosteel No. 1 Casting machine is due to Zhu Zhenyuan's full preparation in the early stage. It took a five -day dot task (I/O interface test), which was successfully completed in less than two days.

There are two seat belts on the top of the team lounge. The team members said that it was Master Zhu's "special product". Every time I encounter a more dangerous occasion, Zhu Zhenyuan has always been a soldier and insisted on debugging in person. The apprentice Zhang Gelei remembered that during the construction of Zhanjiang No. 1 sintering machine, Zhu Zhenyuan accidentally stomped his feet and swollen like a steamed bun. Nevertheless, he still insisted on staying on the front line of construction and completed the debugging task every day to guide the team through the intercom. Everyone persuaded Zhu Zhenyuan to go back to rest. Zhu Zhenyuan said: "I can't stay in the dormitory. I have to go to the scene. There are fewer tasks. I don't worry." He assured the team members to walk as little as possible every day. Four months later, when the project was successfully put into production, Zhu Zhenyuan's foot injury had not completely cured.

In the eyes of his apprentice, he is a "Dinghai God Needle". As long as the master is present, everyone will feel it. He discovered the problem, he tirelessly explained, how the problem came, what consequences, and which solution was the most efficient and convenient. The apprentice sometimes made a mistake, and he always treated tolerance and never blame it. For many years, Zhu Zhenyuan brought out more than 20 apprentices, almost all of the backbone of the industry.

In the "Zhongye Sky Gongci Cup" electrical installation competition, Zhu Zhenyuan competed with his apprentice Li Jian in the "Zhongye Tiandong Cup" electrical installation competition. Someone said to Zhu Zhenyuan: "You are a master, why do you have to participate with your apprentices. Win, you should have, lose, and have no face." Zhu Zhenyuan just smiled. During the competition, at the critical moment of the installation, Zhu Zhenyuan came behind his body, and he looked back subconsciously. Turn your head again, and the connection line is wrong. When calling, the equipment could not run, and Zhu Zhenyuan's cold sweat came down. Generally speaking, when this situation is encountered in the game, people are covered. Zhu Zhenyuan let him calm down. He turned off the power, restored his calm, and began to analyze the problem. Take out the multi -purpose pen, a few points, the failure will be found. Because of this episode, it was delayed for more than one minute. In the end, Li Jian won the first place, and Zhu Zhen was ranked third. He congratulated his apprentice happily, without taking the so -called face at the same time. "What face is not face", Zhu Zhenyuan laughed. "The apprentice is doing well is the biggest face of the master." In the end, both the teachers and apprentices were awarded the title of "National Technical Expert".

I asked Zhu Zhenyuan: "Has the work for so many years made you feel particularly memorable and particularly fulfilling?" "What's special", he laughed, "I am used to it." After thinking about it for a while for a while He said: "When he was young, he was about thirty years old. For the first time, he independently adjusted the entire set of oxygen stations electrical and instrument equipment and met the production conditions. It is quite interesting to do technology, it will keep doing it all the time. "

At the end of the interview, it was time for dinner, and I hurriedly resigned. The next day, Zhu Zhenyuan will drive more than 800 kilometers of cars and go to new projects. I said, "Master Zhu has worked hard." He showed a iconic smile again, as if he was talking about what was. For an electrical engineer, this is just an ordinary day.

Biography

Zhu Zhenyuan, male, born in May 1970, high school, a member of the Communist Party of China, China Twenty Metallurgical Group Shanghai Twenty Metallurgical Construction Co., Ltd. Self -Control Division's Self -Control Division's Debugging Team, Senior Technician, National Technical Expert, Central Enterprise Technology Expert, Shanghai ConstructionThe outstanding talents of transportation and Shanghai craftsmen in 2016 have deep accomplishments in electrical installation and debugging.About the Author

Lu Ming, university teacher, director of Shanghai Writers Association, etc.

- END -

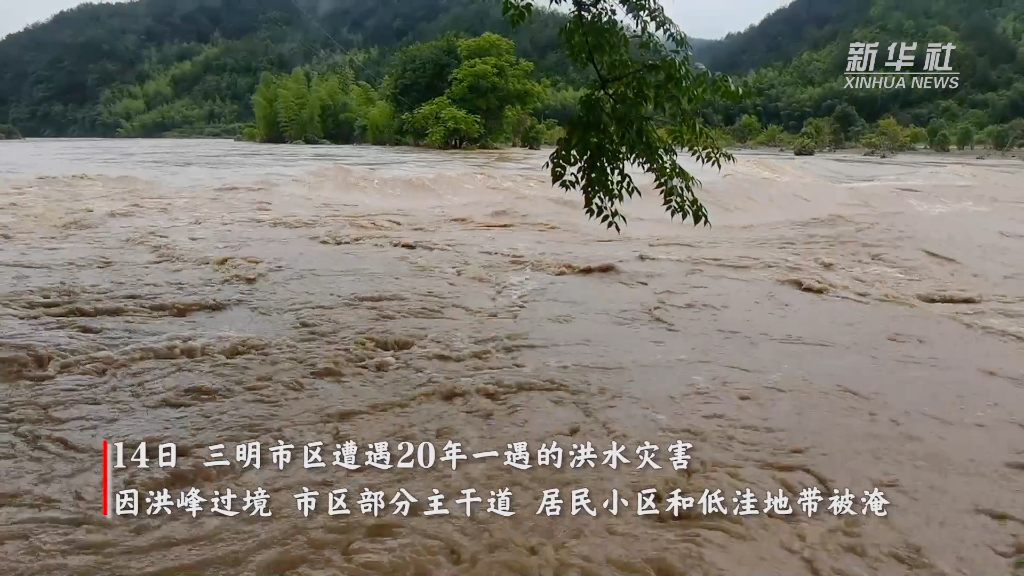

Anti -geological disasters are busy self -rescue -Fujian Sanming actively respond to heavy rain flood conditions

According to the Flood Control Department of Fujian Province, from the 16th to 18t...

Preparation of "Five Levels" to help early to help

According to the preliminary prediction of the meteorological department, the climate of the flood season this year is complicated and the flood prevention situation is severe. In order to do a good j