Strive to build the "Heart" Yucheng Replacement Station of Western Power East to the East of the Western Power East, Jiangsu Province Writing Visual Answers

Author:Yangzi Evening News Time:2022.07.01

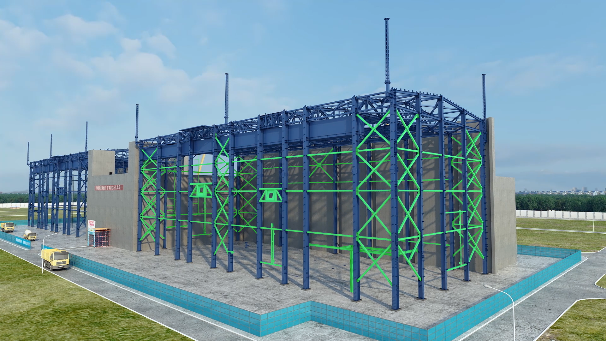

In Jiangnan in June, green fat is red and thin, full of vitality. In Luojiayu Village, Zhangqiao Community, Xinzhuang Town, Changshu City, Jiangsu Province, a large -scale stream of stations are stepping up construction. The gray iron tower, silver cable, and red current transformer are dazzling in the summer sun and full of technology. This is the second (second only to the Three Gorges) in the world's second (second only to the Three Gorges), and the Baihetan-Jiangsu ± 800 kV high-voltage DC transmission project in the world under construction is the Duanyu City replacement station. After the project is completed and put into operation, 312 billion kilowatt -hours of electricity will be transported here from the UHV -in transmission lines from the Baihetan Hydropower Station in Jinshajiang, Sichuan, and then transported to Jiangsu and East China, which greatly helps economic development and environmental quality improvement.

Right now, the construction of the Yucheng Stream Station enters the sprint stage. The pioneer of the party member of the Jiangsu Provincial Power Transfer Company led all the construction staff to work overtime, sprinting the second stage of the operation target. "Su sent" people, listening to the story of the bright and original answer sheet at the hot air construction site.

[Early Heart Answers 1] Technical innovation frequently produces "Soviet Send Model"

The Yucheng changing station is currently the largest high -voltage DC project in the world's largest construction scale and the highest level of technology. The total land sign area is 35.06 hectares, the newly built -built -changing capacity is 8000MW, and the voltage level is ± 800 kV. Change stations. Jin Zhenqiang, the person in charge of the project, told reporters that due to the large construction scale, high technical level, difficult construction coordination, and tight construction period, more than 2,000 people in Jiangsu Province have invested more than 2,000 people to participate in the project. Conversion valve installation, sub -system debugging and partial test work. Facing the glorious mission of building the world's largest and most technological level, party members have rushed to the front line of construction process exploration and innovation, and took out one after another "Soviet -send model".

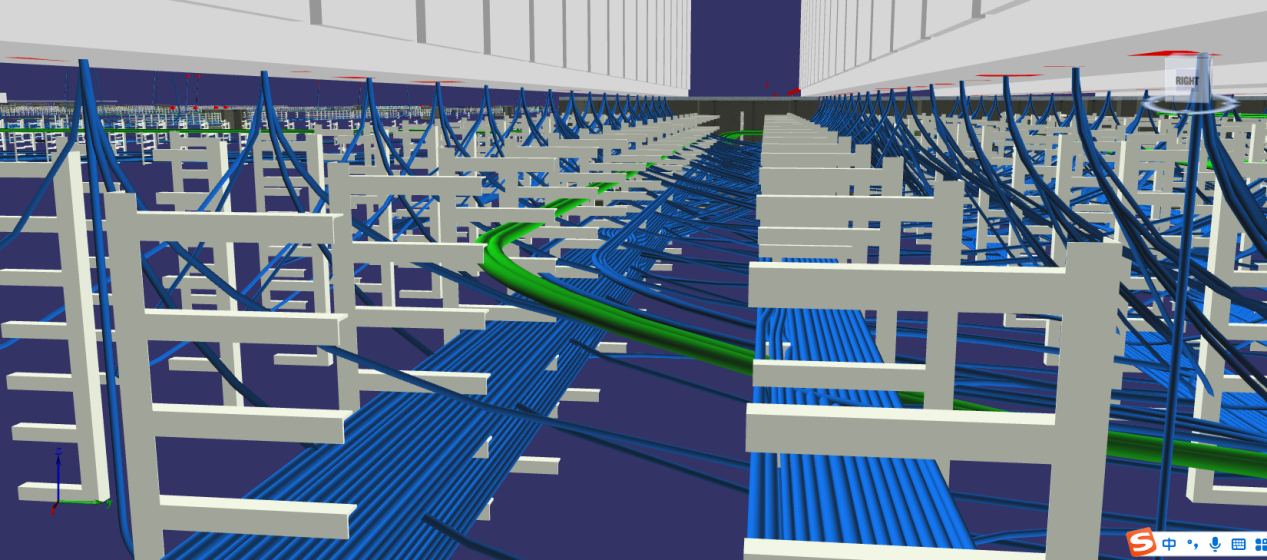

Three -dimensional digital cable laying system to open the "meridians"

The cable is the "blood vessels" and "nerves" of the stream station. The paving of the cables of the Yucheng Streaming Station, there are problems in the number of cables, large cable laying, and high experience in laying experience. The total length of the routine stream stations is about 1300 kilometers, while the total length of the cable of Yucheng Streaming Station is more than 3,000 kilometers. Construction projects are construction projects. The ministry chief worker auspicious and three other chief workers led the research and development. Based on the mature construction experience of the Jiangsu Province delivery company, the three -dimensional digital cable laying system was designed. The cables are arranged and simulated in the channel, three -dimensional visual display on the computer, and supports roaming and positioning operations. At present, some functions of this system have been applied to Yucheng Streaming Station, which greatly improves the quality of cable construction. The construction time has been shortened from 6 months to 4.5 months. The construction period is shortened by about 45 days. At the same time The precise control of the auxiliary materials can be promoted to all substations.

Electronic pressure integrated equipment allows "medical examinations" and "less effort"

As the "goalkeeper" of the entire project, the commissioning branch undertakes the duty of the final control, that is, the quality and wiring of the equipment installation of the equipment are comprehensively inspected by simulation and power -on test, and the project is officially launched to "send electricity preparation". Wang Xiangjun, the chief worker of the debugging branch, told reporters that the "one -time" test has a large workload. The original use of the previously used is relatively bulky, weighs 60 kg, and there are many components. After that, he led the technical personnel of the branch to consider using electronic pressure regulation to improve the streaming equipment. After several months of exploration, the electronic pressure -regulating integrated equipment was successfully developed, with only 20 kg, and the weight was reduced by 2/3. The same workingload was reduced to half of the original. The personnel investment was only 70%in the past, and it also reduced The labor intensity achieved the effect of "less effort".

The Yucheng stream station is a DC stream station. Among them, the low -pressure pressure pressure test of the streaming valve is the key to testing whether the stream -changing valve equipment and the entire control system can work normally, but it has not been found to have a suitable resistance load module and oscilloscope. Essence The original resistor box was particularly large and weighing 250 kg. In order to solve the problem of bulky resistance, at the beginning of the project, Wang Xiangjun led the team to design a resistor box that can flexibly change the resistance value, which weighs only 25 kg, which is reduced to the original 1 /10, it has a voltage function, which can not only meet the load demand during the test, but also ensure the safety of on -site voltage collection. Because the load box needs to bear more than 2,000 volts, and the flexible combination resistance method can reduce the collection voltage. For example, as long as a resistor is used to use 50 volt voltage, the entire voltage waveform can be displayed. In addition, the display wave instrument has also changed from the original hard connection to the collection unit to recording waves through the network cable to effectively improve the security of the test items. The test was used for testing. The original 10 -hour test was only 6 hours, which is equivalent to saving personnel investment.

The cost of saving inspection for the on -site oil and gas laboratory is 520 hours

There are 33 changes in the entire station of the Yucheng Stream Station, 54 stations, 54 oil -immersed current transformers oil samples, and 6799 bottles of hexarin sulfur gas. If the sample is sent to Nanjing 204 kilometers away Testing, it takes 6 hours to go round -trip drive alone. In order to save time and effectively respond to emergencies during the debugging process, Jiangsu Provincial Transfer Company has set up an on -site oil and gas laboratory. This is the first landing project site on the oil and gas laboratory. As a green laboratory, the laboratory uses solar power generation to power the on -site laboratory and transport the excess power to the power grid to efficiently use clean energy to reduce carbon emissions. With this laboratory, there is no need to send a special car to the Nanjing laboratory for physical and chemical analysis. You can conduct tests in a timely manner to save the cost of inspection for nearly 520 hours and save more than 35,000 kilometers. "Matrix Management" mode efficiently coordinates a variety of work surfaces

The work site of Yucheng changed stations is wide, with a maximum of about 32 operations. The construction period, quality, and safety requirements are very high. Zhang Biliang, the person in charge of the civil construction project site, led the team to innovate the use of vertical management and divide by professional division and divide by regional divisions. The combined "matrix management" model combined with horizontal management has given full play to the professional strength and management level of team members. This model is selected as the "13th Five -Year Plan" team of State Grid Jiangsu Electric Power Co., Ltd. to build an excellent typical experience.

[Early Heart Answers 2] Gathering the heart to show the "Su Du Ying"

At the construction site of the Yucheng Stream Station, the construction workers were running the target at the end of June by the end of June. Because of the epidemic, many people have been working on the scene for more than 100 days since the Spring Festival. It was the iron army of the "Su sent".

Benefits: No matter how small the problem is

Jin Zhenqiang, the person in charge of the electrical construction project, was busy running at the scene every day. He was often soaked by sweat. Because of this, every detail on the scene became bamboo. In the daily inspection of the construction site, he can find a lot of safety and quality problems, such as the ground box box is not done, the line hat number is wrong, etc. From finding these subtle problems Beauty and meticulous. In April, on the eve of the first phase of the flow station, he always coordinated various tasks in the face of problems and emergencies. When he found a major defect in the exposure of the cable in the stream -changing oil pool, the solution was immediately proposed, and the slot box was installed at the naked cable, and the gap was blocked with fire prevention materials to prevent oil pollution pollution pollution during streaming and oil pollution pollution. cable. After the problem was resolved, he hurried to the next destination.

It is precise grasp of the project situation that the subsequent power delivery is guaranteed, and the concern for employees and family members has given the Yucheng Project Department with feelings and temperatures. Not long ago, the wife of Li Jingfu on the scene was sick, but she could not go back to take care of it due to the epidemic. After learning about the situation, Jin Zhenqiang immediately coordinated the procurement of medicines and sent it to his home as soon as possible to solve the urgent need.

Gen Xiaojia Gu's overall situation: 24 hours insist on the construction site

On March 10, 2021, the civil construction project of the Yucheng Stream Station was officially broken. Before that, as a high -end valve hall area of the core area of the stream station, the construction of the pile must be completed in advance. Zhang Biliang, the person in charge of the civil construction site, welcomed the difficulties and signed a military order on January 14 to ensure that the 1024 irrigation piles of the high -end valve hall were completed by February 5. He led the project management team to plan in advance, optimize the construction plan, coordinate the arrangement of construction, overcome the difficulties caused by rainstorms and high temperatures, and promote the progress of the project in an orderly manner in accordance with the predetermined target.

At 9 pm on January 17th, Zhang Biliang received a phone call from his wife: "The son seems to be not comfortable and the mental state is not good." Zhang Biliang replied: "Then you pay more attention to observation, I'm still on the scene!" At 12 o'clock in the night, Zhang Biliang received the phone again: "My son has a fever, and my parents have returned to my hometown. Can you help me call me a car first? I put on my son and wait for the car to take him to the hospital." , I call you the car downstairs. If you take your son to the hospital, be careful, what will happen in time! "During that time, the high -end valve hall of Yucheng changed the high -end valve hall was continuously constructed for 24 hours. Manager, as a party member, Zhang Biliang led all the staff of the project department to meet the difficulties and took the initiative to take the initiative to duty to 12 o'clock every night. That night, Zhang Biliang slept all night. His son hung water in the hospital. He organized the construction site to coordinate the construction overnight, breaking the 36 irrigation pile plan of the booking, reaching 40 piles. The next afternoon, his son finally had a fever. When he learned the news, Zhang Biliang still insisted on the construction site. He was relieved and continued to launch an impact on the new work goal.

Under the organization and coordination of Zhang Biliang, the project department invested 12 drilling pile drills and 72 pile foundation workers in one -time. The two -shift system was implemented, which lasted 32 days and nights. It was successfully completed at 3 pm and lived up to the responsibility of the mission, showing the style of the iron army.

Forgotten me: "Rain Night Battle Map" is the best cohesion.

Wang Xiangjun, chief engineer of the debugging branch, is a "young old party member". The 38 -year -old party has been 16 years old. At the project site, he led the team to condense the difficulties. It was him who walked. The construction time of Yucheng's streaming station is very tight. Considering the safety problem, the rising test for the quality of the project can only be performed at night. In order to ensure the progress, it is necessary to work overtime for a week, and it will be 12 o'clock or even 2 o'clock every day. Wang Xiangjun said: "The lift test is performed outdoors. When it comes to rainy days, the first thing comrades think of is the canbar protection equipment, so as to ensure that the test can be carried out smoothly. , Outdoor temperature is very low, the cold rain hit the body without complaints without complaints. I think this is the best portrayal of cohesion. "Taking the project as the home: timely discovering the amount of consumables in time

Taking the project as the home, the construction site as the home, the "Su Du" people have finger and care for the "family". Chen Yan, chief worker of the electrical construction project department, told reporters that during the construction process, the amount of ground materials for a single valve cold equipment were different from the actual cognition. The high -end to the low -end of the bipolar to the bipolar, use laser ranging, steel tape measure and other tools to carefully measure the grounding material of the valve cold equipment, and finally calculate a more reasonable result: the amount of ground material is 2400 meters, and the design dosage is only 1000 Mi, half less! At that time, during the epidemic period, if it was transported to the construction site according to the amount of materials designed in the original design, replenishment will definitely affect the construction period. Chen Yan immediately communicated with the design institute and adjusted the amount of ground materials to avoid the tight purchase time of later materials and could not enter the construction in time.

At the construction site of the Yucheng Stream Station, the night battle of the lights became a daily life. The "Night Class" of the Chen Yan team has a "self -selected action": patrol home. Chen Yan explained that when other professional construction teams or brother units, when construction in our construction area, there is a certain uncertainty and is always a little uneasy. Everyone will take the initiative to the scene after dinner every day. There is no work task, and I also habitually go to the scene to go and take a look to prevent other brother units from being damaged in the valve hall during the construction process because of some errors or operations. Under the careful care of all members, since the construction of the construction area for half a year, the 318 equipment of the Chen Yan team's construction area has good installation quality, and the completed high -end valve hall has achieved "zero defects".

Yangtze Evening News/Zi Niu Journalist Qin Xiaoyi

Edit: Qin Xiaoyi

- END -

Between the inside roll and lying flat: no need to be pessimistic about the mobile phone industry

Title Picture | Vision ChinaHave you ever thought about this problem: You and me, a...

Beijing's first Bitcoin "mining" contract in the second instance of the original judgment maintained

Recently, the Beijing Third Intermediate People's Court sentenced the Bitcoin mini...