Schwarn parent company Hangao Environmental Swending Adhesive solution to promote the industry's green production

Author:China Economic Network Time:2022.06.24

Recently, the green demand of Schwarn's parent company Han Gao Ying's shoes production industry and sports fashion market has launched a more efficient and environmentally friendly water -based type and PUR hot -melt glue solution. Simplify the advantages of solutions and vast resource network layouts, and customize more sustainable shoe business growth maps for customers and partners.

As a sustainable pioneer in the global adhesive market, for many years, deep cultivation and fashion industries have launched a series of high -efficiency and sustainable environmentally friendly shoe bonding solutions with excessive research and development bases and technical products. Partners break the technical misunderstanding and inject green and efficient production kinetic energy.

The birth of a pair of shoes needs to be described as the key to the adhesives and treatment agents that play a composite bonding effect between shoe materials. In recent years, the sports fashion industry is "getting greener" at the speed of visible to the naked eye -consumers have begun to find more environmentally friendly labels that mean lower carbon emissions and more responsible production when buying sports shoes and clothing. To achieve the "doubles" of environmental protection efficiency and economic benefits, shoe manufacturers must accurately cut questions from the aspects of material technology and process processes to find the optimal solution of green and high -efficiency shoe production.

Popular science of shoe making technology: starting with the smell and VOC content of shoe glue

For a long time, in order to better protect the professional safety of workers and purify the production environment, more and more shoe brands have put forward stricter environmental protection requirements for adhesives. To determine whether the adhesive is environmentally friendly, the fundamental question of the selected raw materials is required. Environmental adhesives are based on benzene -free materials and do not contain toxic substances. Among them, the content of volatile organic compounds of water -based adhesives is zero, which can better ensure a safe production environment and protect workers' health.

At present, the industry is mostly one of the authoritative standards for judging the environmental protection attributes of adhesives (hereinafter referred to as VOC) with volatile organic compounds (hereinafter referred to as VOC). According to the definition of the World Health Organization, VOC is a melting point below room temperature, between 50 and 260 ° C, and a total of volatile organic compounds. The general name is that we are familiar with the benzene, two metrics, formaldehyde, etc. Transportation, energy fuel, furniture building materials, etc. are common sources of VOC. For the shoe industry, the traditional oily glue and oily treatment agent commonly used in the production line are also VOC emissions "severe disaster areas".

Because VOC is harmful to the human health and ecological environment, my country began to implement the "Limited Limited Edition of Adhesive Volatility Organic Compounds" as early as 2020 (hereinafter referred to as "national standard"), including shoes, luggage, construction, transportation, etc. The variety VOC content in multiple applications is clearly stipulated.

According to the national standard, the adhesives are divided into solvent -type adhesives, water -based adhesives, and body type adhesives according to their decentralized media and content, and indicate the test methods, inspection rules and packaging signs specified in various types of adhesives in different application areas. Among the three types of adhesives, the water base type is identified as a low VOC adhesive. Therefore, compared to traditional oily glue, water base type, and PUR hot melting glue solution is a better choice for shoe brands to meet the national standard requirements and realize green production.

Han high environmental shoe solution: not only for sustainable and efficient choices

Significantly reduce VOC emissions: Highwater and PUR hot -melt glue solutions do not contain trima and VOC. Compared with traditional solvent -based products, Han high -water products can reduce VOC emissions up to 93%. Calculated by the annual production of one million pairs of shoes, traditional solvent -type products will generate 100 tons of VOC emissions. If you turn to Highwater -based solutions, the saved emission treatment cost is equivalent to 70,000 euros. In terms of VOC's emission reduction, the high -water water nature and PUR hot -melt glue solution are more in line with the strict national standards and European standard standards, helping customers to develop a greater domestic and foreign production market and embrace multiple business opportunities.

Increasing quality and efficiency, the shadow of immediately: Han high water -based solution adopts two -in -one process simplified technology, which is compared to two to three products in traditional production. The glue automation solution, through advanced automated production processes, greatly reduce labor force, each pair of shoes can save 15 grams to 18 grams of glue. It is worth mentioning that, thanks to a substantial simplified production process, the space utilization rate of workshop has also increased significantly, and the total cost of production has dropped again.

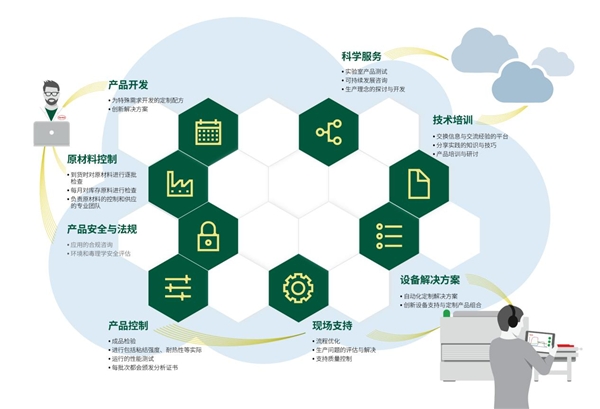

Global layout, closed -loop service: Relying on strong technical strength and a global resource network, Han Gao actively builds a closed -loop service experience for customers, covering product development, raw material control, product safety and regulations, product control, on -site support , Equipment solutions, technical training, and scientific services.

Demand orientation, custom R & D: As a trusted partner, Han Gao has the ability to start customized and precise research and development from the needs of customers based on the needs of customers. Life cycle (LCA) reduces the goals of carbon footprints. This measure can not only promote the green transformation and upgrading of products and ensure production safety, but also a close response to the contemporary my country's circular economy development model.

Han Gao is in action: the green and efficient new change of the shoe making industry

At present, the demand for sustainable development and quality improvement promotes the "acceleration" era of transformation and upgrading. How to grasp market trends and overcome industry challenges are the core issues facing all shoe brands.As a leader in the field of sustainable development, it will not only shape the future of enterprises and create economic benefits with a responsible attitude. At the same time, Han Gao has also made a firm commitment to continue to open up a new solution for sustainable development.In the future, the Han Gao Home Furnishing and Sports Fashion Division will work with more innovative solutions to work together from the climate, circular economy and security three parties to work together to accelerate the green and efficient development of the shoes industry.

- END -

See Mai Huang again

Along with the cry of Xuanhuang Xuan of the cloth bird, the hometown people began ...

The Ministry of Human Resources and Social Affairs announced that the new occupation of 18 new occupations is declared by Zhejiang

Zhejiang News Client reporter Jiang Xinru, correspondent Wang Ling 2Recently, the ...