Is the glass bottle really environmentally friendly?It depends on where you drink the bottle after you drink happy water

Author:Institute of Physics of the Ch Time:2022.06.23

6.22

Intellectual

The Internet

In the production link, the glass with a very high carbon emissions must be increased in the recovery and processing link. Source: pixabay.com

Guide

Bleak

●

○

The glass bottle makes the recycling industry love and painful. Although it is labeling with the "infinite cycle", it is not rising and anti -descending. To achieve carbon neutralization, glass with a high carbon emissions in production links must be paid more attention to effective collection and reuse.

Written article | Jia Yinan

Editor -in -law | Feng Yan

● ● ●

The glass industry often claims that it can be "100 %, infinitely circulating without damage and quality or purity" [1], and "Nature" commented that it is "a treasure material that realizes carbon neutrality" [2]. However, in most countries around the world, the recovery rate of glass is not high.

China is a large glass production country, exported to 25%of the world's glass and glass products [3]. Waste glass is one of the top ten varieties of China's renewable resources [4]. However, today, where other renewable resources recycling and utilization have been greatly improved, the recovery rate of waste glass does not rise and fall. According to the statistics of the renewable resource of the Ministry of Commerce, the amount of waste glass generated in 2019 was about 2.123 million tons, an increase of 10.9%year -on -year, but the amount of waste glass recycling fell by 5.4%(about 9.84 million tons) [5].

People can also echo the above data. Have you ever experienced such an experience? Be careful with various glass bottles and cans, thinking that the glass can be recovered at high value, but when asked about the waste of waste, the answer was "not collected." In fact, there are a considerable part of the bottles and cans around us (the glass source of life) is unattended. Some of them need to be mixed in construction waste to be collected. The final fate is often buried in the ground. [ 6].

1

Happy glass bottles, is it really better than plastic bottles?

In the summer, a bottle of ice and happiness water full of bubbles is the biggest comfort after I receive solar radiation. Although the packaging of happiness is all overwhelmed, from plastic bottles, aluminum cans to glass bottles, how many people, like me, think that the same brand of air bubble water, glass bottle is the best.

Although a brand company has clearly stated that "no matter which kind of packaging, the beverage formula is exactly the same", the packaging will quietly change the bubble water on the shelves but it is true [7].

First, the soul of bubble water lies not only in the ratio of sugar and taste, but also very important bubbles (carbon dioxide). When the bubbles enter the oral cavity, it becomes weakly acidic, stimulating neurons, bringing us a pleasant feeling, bubbles, and bubbles. The existence will also make us feel that the happiness water we drink is more frozen, and it will increase the joy brought by sugar [8].

Bubbles are affected by packaging. Plastic beverage bottles mainly use PET plastic (polyethylene dilate glycol), which is a polymer polymer. During the polymerization process, the polymer chain will be entangled like noodles at will, like this::

Figure 1 The polymer structure schematic diagram of the plastic bottle | source [9]

Such a noodle folding structure is more likely to make the gas transparent than glass and aluminum. Therefore, after a long time, the happy water bubble content of plastic bottles will be a little less than glass bottle and easy tank.

Second, not only plastic bottles are used in plastic, but also a thin layer of plastic coating in the cans of easy -to -pull cans. The coating is to prevent carbon dioxide and metal reaction. Don't worry, they are all safe, but the existence of plastic will slowly absorb the taste of happy water. In contrast, the glass can be said to almost not affect the beverages that are installed at all. Therefore, the happiness water in the glass bottle is the taste of the initial setting of the factory.

2

Is it environmentally friendly with glass?

Due to the advantages of high transparency, stable chemical properties, strong erosion resistance (acid) erosion capacity, glass is widely used in food beverages and cosmetics packaging; because of its easy cleaning and stable enough, many countries around the world have repeatedly used glass bottles to use glass bottles. Stalls selling drinks. In the current wave of plastic reduction [10], glass bottles often appear in the appearance of environmentally friendly substitution. But in reality, the glass bottle is far lower than the former.

If the cycle utilization of the glass bottle is too low, is the glass still environmentally friendly?

This problem is not unique to measure the different conclusions. We talk about several dimensions such as global warming (which can be simply understood as carbon emissions), resource consumption, environmental impact (ecological toxicity, human health).

From the perspective of global warming: glass manufacturing is a high -energy consumption and high -emission industry in the world, and global glass manufacturing produces 86 million tons of greenhouse gas each year [11]. The carbon emissions data in China's glass industry still lacks a unified measurement standard, but some industry estimates show that the manufacturing of daily glass products per ton will bring 0.802 to 0.975 tons of carbon dioxide emissions [12], which means that in China, only daily use in China is only daily for daily use Glass manufacturing produces more than 20 million tons of carbon dioxide each year.

Even so, glass is still called "carbon neutral treasure material" because such high carbon rows are solved.

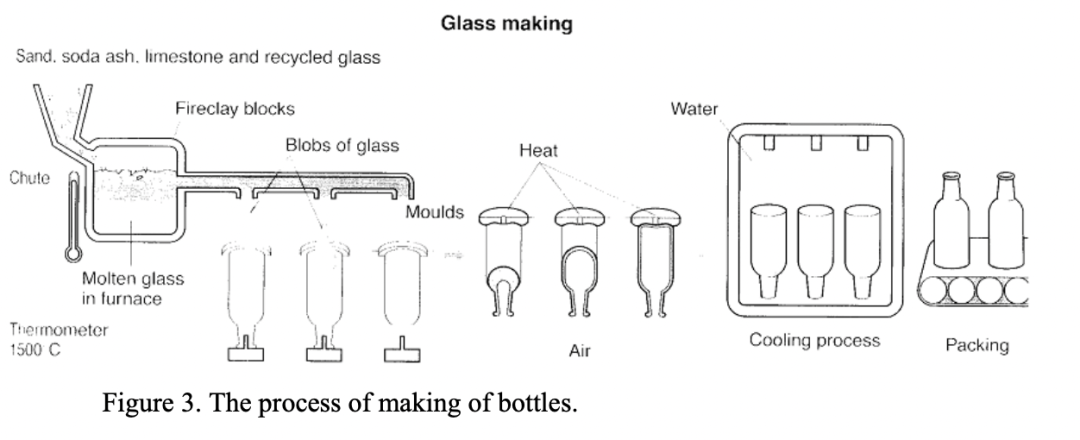

The manufacturing process of glass products includes the following links: raw materials (sand, soda, limestone, etc.) at 1400-1600 degrees high-temperature melting to form liquid glass-enter mold molding-cooling and cooling-transportation. Figure 2 The manufacturing process of glass products | Figure source [13]

Because glass manufacturing requires a high temperature environment, it is currently used as heating raw materials such as coal and natural gas. In addition, the raw materials made of glass are rich in carbon -based (sodium carbonate, calcium carbonate). The process of turning these raw materials into liquid glass will also release a large amount of carbon dioxide [ 14]. Therefore, the firing of glass is one link with the most energy consumption and carbon emissions. Among them, energy consumption can account for more than 70%of the entire manufacturing process, while the carbon emissions during the glass firing process come from the burning of energy, and 36 36 %Come from carbon dioxide from raw material heating [15].

However, the use of recycled glass during glass firing can effectively alleviate the above high energy consumption and high emissions. Based on the estimates of the European Glass container association, each 10% recycling glass is added, the glass manufacturing process can be reduced by 5% [16]. At present, European glass container manufacturing has added an average of 52%of the recycling content [17]. As long as the quality control of the waste glass is good enough, this ratio can continue to increase. If the use of renewable energy is used, glass manufacturing is expected to reach carbon neutralization in the short term. [18]

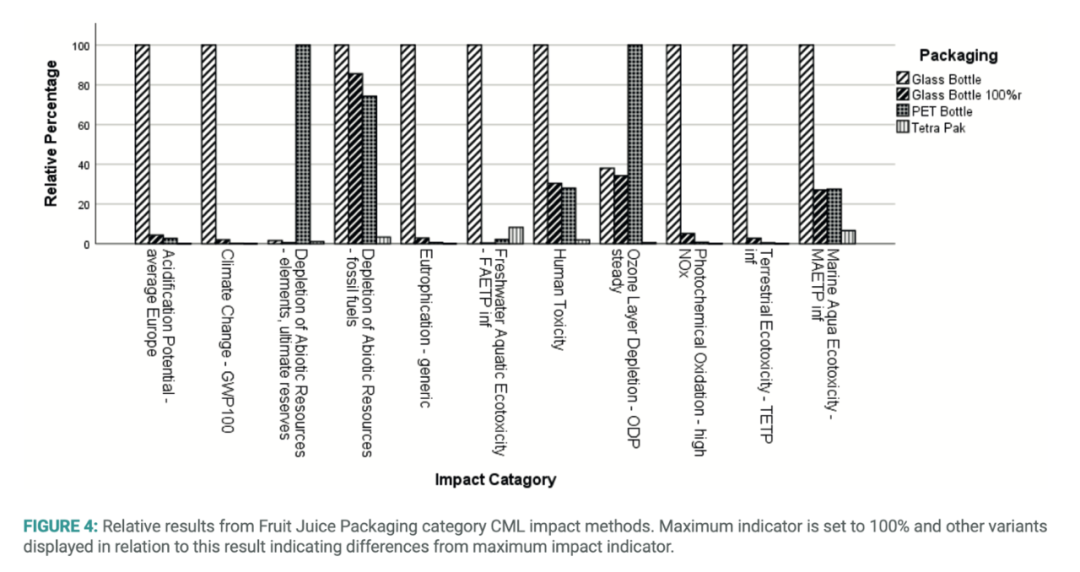

If the calculation includes all links of raw material production-packaging production-product production-packaging-transportation-abandonment, compare the environmental impact of different packaging materials from the full life cycle, glass, plastic, jar, paper-based film (thread bag), etc. As a one -time use, the carbon emissions of the glass bottle will be much higher than other materials [19].

Therefore, if the recovery rate is low, the glass bottle is a one -time packaging, and there is no advantage in the perspective of carbon emissions, which means that it is not environmentally friendly material.

From the perspective of environmental impact: Glass is an irreplaceable material. The time required for natural degradation in the environment is longer than that of plastic, but the glass does not cause soil or air pollution in the environment. "In comparison, if plastic packaging entering the environment will affect the health of the soil and cause marine pollution, the chemicals contained in it may also affect the health of animals and plants and human body." "Of course, there are other alternative materials, such as paper and wood such as paper and wood in the degradability. If it does not contain toxic and harmful chemicals, the harm of entering the environment is less harmful."

From the perspective of resource conservation: the glass industry often says that "glass is a material that can be infinitely circulated" [20], low recycling loss, guarantee of quality, and high use efficiency. The American Glass Association said that the glass from the recycling box to became a new packaging, which only took less than a month [21].

Calculated by one ton, recovering one ton of waste glass can save 720 kg of quartz sand, 250 kg of soda soda, 60 kg of long stone powder, and use 10 tons of coal to save 400 degrees of electricity. After a ton of waste glass, it can renew 20,000 500 grams of wine bottles, and the production cost of new raw materials can be saved by 20% [22]. Therefore, the glass is only used as a one -time instead of recycling, and it is unreasonable from the perspective of resources.

Figure 3 Comparison of the full life cycle parameters of different materials for different materials. The glass (columns of the slash) used at one time have a greater environment than other materials.

3

What if the packaging is not used at one time?

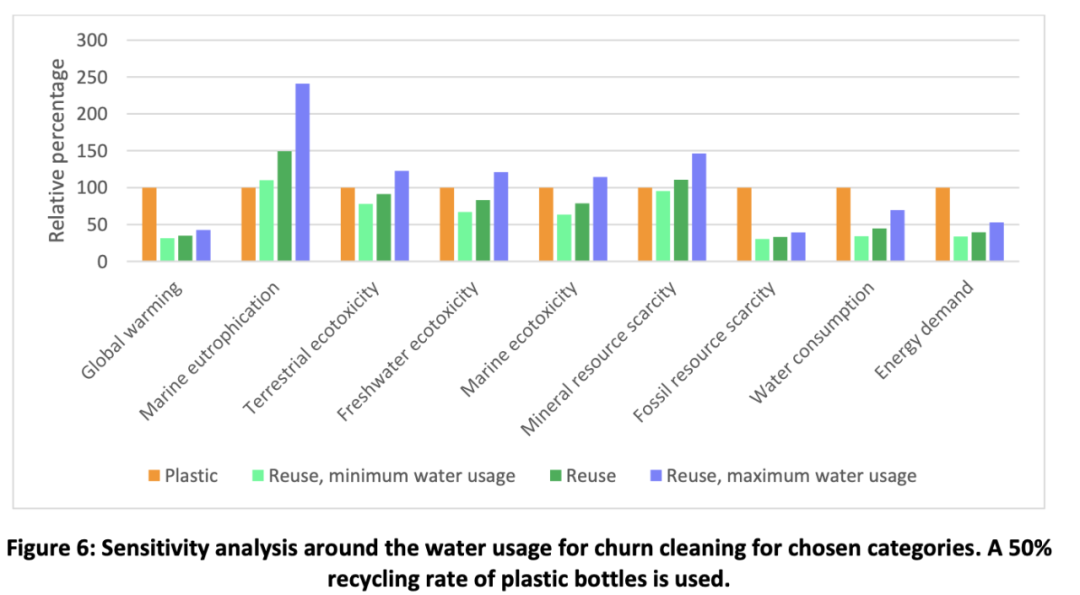

Although the market share of reassembly bottle beverage market is not as good as before, this model is still not uncommon at home and abroad. Especially with the expansion of cycle economy solutions in recent years, more and more regions and brands have begun to re -explore the reuse model to reduce the production of packaging waste [24], and more related life cycle research has also appeared. Essence

These studies basically use the method of "from the cradle to the grave", and the calculation includes all links of raw material production-packaging production-product production-packaging-transportation-abandonment. The comparison environmental impact index also covers the level of global warming, resource consumption, ecosystem impact (ozone layer consumption, acidification, ecological toxicity, etc.), human health (human toxicity) and other levels.

These studies are divided into several directions for a certain product, such as Brazil's soft drinks, Italian beer, French wine, British milk, etc.:

● Compare the environmental impacts of packaging materials such as glass, plastic, jar, and paper -based film (threads) from different dimensions. Essence

● The proportion of packaging and one -time packaging is compared to increase or decrease, and the best proportion of balanced environmental and economic benefits is found.

● How many times do you need to evaluate the duplicate use of packaging and the best environmental benefits.

Because each product is different in each region, the comparative conclusion of the research cycle of life cycle is not the only one. The key factors that affect the final result can be summarized as: the duplicate use rate of packaging, the self -weight of the packaging, and the recycling after the packaging abandoned. Utilization rate. In summary, most research conclusions believe that reused packaging will be better than one -time packaging environment [25].

Take Brazil's soft drink as an example. Studies have shown that the reuse rate of glass bottles has reached 40 times better than other packaging environment [26], while Italy's research on red wine packaging proposes that the glass bottle reuses 15 times, and you can then you can. Have the best environmental performance [27]. In summary, if the glass bottle is used only for one -time, due to the high energy consumption of weight and production process, it cannot be comparable to other materials on the environmental impact index. It is a packaging material with great environmental impact. But as reuse, it can be a good choice.

Taking the research results of milk packaging as an example [28], if the milk glass bottle is reused and washed in the water saving model, compared with the disposable plastic bottle on multiple environmental indicators, it is better:

Figure 4 All life cycle comparison: Milk disposable plastic packaging VS reusable water -saving model, normal model, and no water mode of glass packaging

Earlier, a study of Britain's carbonated beverage packaging showed that if the glass bottle was reused once, the emission reduction benefits could reach 40%; reused more than 8 times, and the emission reduction contributed 65% [29]. The whole life cycle study of a beer packaging in Portugal shows that the proportion of reuse of packaging is not necessarily the better. If the glass packaging sold in the region is 20-50%of it (the rest still uses the remaining ones still use Disposal packaging), as long as the beer glass is reused once, it is reduced than the environmental impact of one-time packaging; if the proportion of packaging is increased to 60%, the reusable use requires 3-4 times to see a better one. Environmental benefits; and when the proportion of packaging is increased to 85%, reuse will actually bring greater environmental impact more than one -time packaging [30].

4

There are many benefits, what is the situation now?

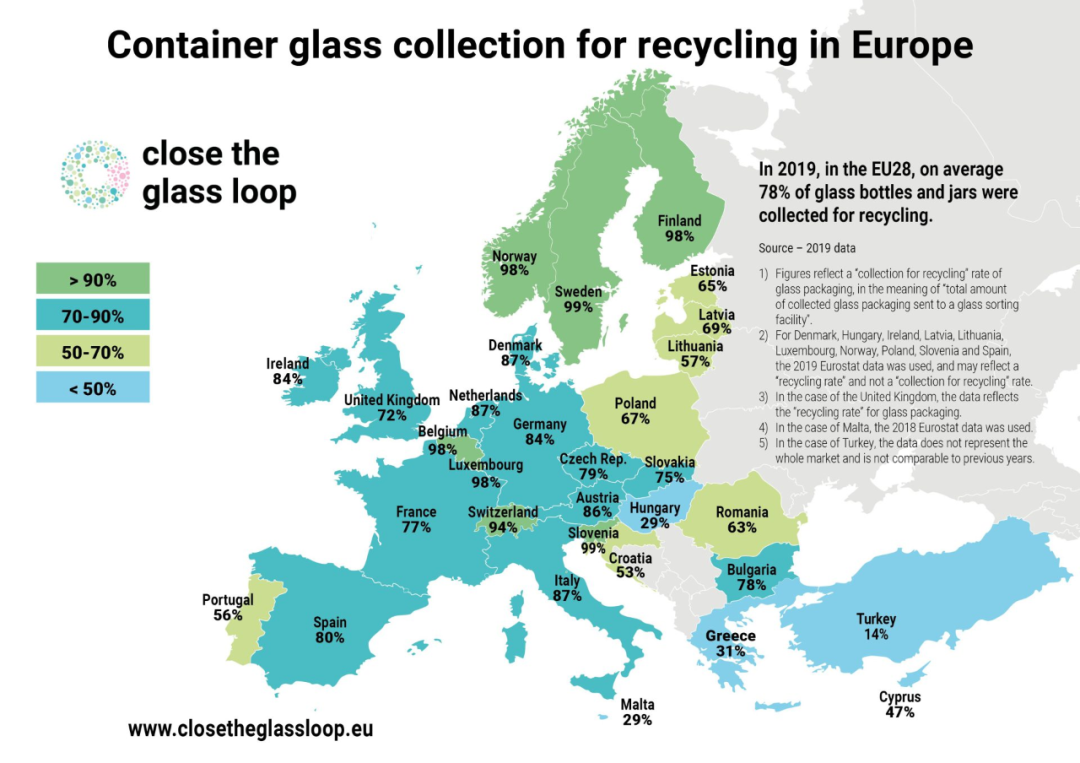

At present, the average collection rate of glass containers in the European Union is 78% [31], and the goal of the EU Glass Industry Association is by 2030, and the collection rate of glass containers after consumption will reach 90% [32]. Some countries in the European Union in glass containers are also very beautiful in the reuse and repeated filling. Take Germany as an example, developed a mature deposit return system to effectively collect glass bottles. The glass bottle repeatedly fills 50 times. [33 ].

The deposit return system is the practice of "taking 5 pieces of soda bottle and drinking 4 pieces here" beverage bottle deposits. When buying a drink, pay a certain deposit for the packaging. Essence In some European countries, the deposit return system has developed more mature, and the cooperation of brand merchants and large supermarkets has expanded the scope of bottle return.

Figure 5 The recycling of glass containers in Europe | Figure source [34]

The deposit system is an effective recycling policy in Europe and the United States. According to statistics from the American Glass container association, the average recovery rate of glass bottles in the United States is about 31%(3.1 million tons) [35]. In the state with a deposit return system, the recovery rate of glass containers can reach 63%; in the state without a deposit return, the average recovery rate is only 24% [36].

In China, the recovery rate of daily glass is about 30%, and the recovery volume has declined year by year, and the market price of waste glass is low.

Chengdu Aobei Environmental Protection Technology Co., Ltd. has been paying attention to the field of recovery for a long time. Its founder Wang Jianchao told "Intellectuals" that "the recovery price of scrap glass per ton is 200-500 yuan, which is compared to a cardboard of more than 1500 per ton and 1800-2500 yuan per ton. Plastic bottle, low glass recovery price, heavier, less income per ton, sometimes even losing money, which is considered to be "hard -working" recycling. "

Glass is defined as recyclable in municipal waste classification, but because there is almost no profit for glass recycling, traditional recycling channels are unwilling to collect. Stay to the construction industry and become a building material for paving and building buildings. In the context of the overall downturn in China, there are also practitioners who sell waste glass to Africa and other places [37].

At present, the main force of glass recycling is more companies that are positioned in the construction of garbage resource -based channels like Aobei Environmental Protection. However, the number of comprehensive utilization enterprises for waste classification and recycling is limited, and waste glass containers are very scattered in the city. It also means that a large amount of waste glass has no channels to be retracted, and there is no stable waste glass supply. Cost and difficulty.

Investigating the fundamental, the low recovery rate of the glass is due to the decentralization of the user, the small recycling channel, and the high cost of the cost. High costs; insufficient back -end market demand, decreased manufacturers engaged in glass processing, and low recovery prices.

"More than ten years ago, a beer bottle recycling price could be 3 cents, because some people would be cleaned and reused after recycling. But now, it is not referred to as the weight. The diversification of packaging and packaging also increases the difficulty of reuse. In addition, the glass bottle reconstruction process requires that the cost of glass regeneration is high and the regeneration is more expensive than the original material, which directly leads to the no market for glass bottle recycling. "Wang Jianchao said.

Glass container also has similar recycling problems in other countries. For example, in Malaysia, due to the low demand for recycling and regenerative glass, no recycling profits, and lack of recycling of waste recycling for manufacturers. 38]. Du Huanzheng suggested that the recovery of glass needs to be improved to improve the collection-processing system. Taking Shanghai as an example, 800-1 million tons of waste glass generated in Shanghai each year, about 60%of them come from residents' domestic waste, about 25%of construction waste, and about 15%of the processing plants [39]. According to different sources of waste glass, different recycling methods are adopted, typical enterprises such as Yanlong Foundation have established a three -level acquisition network of waste glass. Fixed -point recycling.

In addition, the recycling cost of waste glass is not low, and the large -scale and sustainable development of the industry requires stable funds. However, the current profit of market profits cannot be supported, and government subsidies are not long -term. Therefore The responsibility extension system, the establishment of glass container manufacturers and user payment obligations, and providing long -term stable financial support for the recycling system of waste glass to ensure the steady development of glass recycling and reuse industries.

In view of the many reuse benefits of glass bottle, the policy should also clearly give priority to the development of reuse, guide the market to establish a more effective system to promote the reuse rate of glass, and encourage local life cycle research to guide various industries to set up in specific business models to set up in specific business models Determine the most suitable reuse rate.

"If the amount of packaging cannot be reduced from the source, the effective collection and processing of waste cannot be achieved, and no matter which material is used, it cannot fundamentally solve the problem of waste incremental and environmental pollution." Du Huanzheng said.

As a consumer, let us enjoy the purest and most happy and happy water brought by the glass bottle, and remember that the bottle that blends the money must be returned, so that it can be repeatedly used; Please put it in a recyclable box for the bottle and let it circulate again.

References: (can be browsed up and down)

1.https://www.gpi.org/benefits-OF-GLASS-PACKAGIN

2.https://www.nature.com/articleS/d41586-021-02992-8

3. Https://www.worldstopexports.com/top-glass-nd-glassware-Exports-di-country//

4.http://ltfzs.mofcom.gov.cn/article/ztzzn/201605/20160501320275.shtml

5.2020 China Renewal Resources Recycling Industry Development Report

6.http://m.news.cctv.com/2020/08/23/Arti7EdezCTFERU0URALCPDT200823.shtml

7.https://www.myRecipes.com/how-/why-glass-kke-bottles-taste-better

8.https://www.popsci.com/sclence/article/2013-07/fyi-carbonated-water-dDictive/

9.http://read.nxtbook.com/wiley/plasticSengineering/september2016/ConsultantScorner_plastics.html

10.https://www.theatratic.com/ideas/archive/2022/05/se-plastic-chemical-recycling-disposal/661141/

11.https://www.nature.com/articleS/d41586-021-02992-8

12.https://mp.Weixin.qq.com/s/kz2lgcg3Ghjidti9nn3n5eg

13.rajab, nadine n .. "The proces of macking glass bottles." (2016).

14.https://www.sciencedoze.com/2021/02/manUFACTUR

15.Michael Zier, Peter Stenzel, Leander Kotzur, Detlef Stolten, A review of decarbonization options for the glass industry, Energy Conversion and Management: Volume 10, 2021.16.https://www.nature.com/articles/d41586-021- 02992-8

17.https://feve.org/wp- content/uploads/2019/07/recycled-feve-posity-june-2019.pdf

18.https://www.nature.com/articleS/d41586-02992-8

19.Brock, Alice Williams, Ian. (2020). Life Cycle Assessment of Beverage Packaging. Detritus. 13.47-61. 10.31025/261135/2020.14025.

20.https://www.gpi.org/benefits-OF-GLASS-PACKAGIN

21.https://www.gpi.org/benefits-OF-GLASS-PACKAGING

22.https://www.chinacace.org/tech/view? ID = 9954

23.Brock, Alice Williams, Ian. (2020). Life Cycle Assessment of Beverage Packaging. Detritus. 13.47-61. 10.31025/261135/2020.14025.

24.https://www.packworld.com/isSues/sustainability/article/21196402/reusable-nd- refilistic-packaging

25.https: //zerowasteeurope.eu/wp- content/uploads/2020/12/zwe_reloop_executive-summary_reus-Vse-packaging

26.Almeida, C.M.V.B.; Rodrigues, A.J.M.; Agostinho, F.; Giannetti, B.F. Material Selection for Environmental Responsibility: The Case of Soft Drinks Packaging in Brazil. J. Clean. Prod. 2017, 142, 173–179

27. Ferrara, C.; DE Feo, G. Comparative Life Cycle Assessment of Alternative Systems for Wine Packaging in Italy.

28.Błażejewski, T., Walker, S.R.J., Muazu, R.I. et al. (1 more author) (2021) Reimagining the milk supply chain: Reusable vessels for bulk delivery. Sustainable Production and Consumption, 27. pp. 1030-1046. ISSN 2352-5509

29.Life cycle environmental impacts of carbonated soft drinks, David Amienyo Haruna Gujba Heinz Stichnothe Adisa Azapagic30.Carlos Costa, Life cycle assessment of different reuse percentages for glass beer bottles, The International Journal of Life Cycle Assessment, 2021

31.https://feve.org/glass_recycling_stats_2019/

32.https://packagingeurope.com/eu-glass-packaging-notustry-aims-5-90-reycling-collection-raate/2836.rticle

33.https://www.dw.com/en/how-does-germanys-deposit-scheme- )-50923039

34.https://feve.org/glass_recycling_stats_2019/

35.https://www.epa.gov/facts-nd-figures-about-waste-and-recycling/glass-material-specific-data

36.https://www.gpi.org/glass-recyCling-Facts

37.http://www.xhby.net/index/202205/t20220520_7549766.shtml

38.https://www.thestar.com.my/news/nation/2022/05/19/no-market-recycled-glass-bottles

39.http://ltfzs.mofcom.gov.cn/article/bb/2018080802773488.shtml

Reprinted content only represents the author's point of view

Does not represent the position of the Institute of Physics of the Chinese Academy of Sciences

Source: Intellectual

Edit: Cloud Kaiye

- END -

The Liangshan Prefecture Market Supervision Bureau has carried out in -depth inspections of large -s

In order to fully implement the spirit of the TV phone conference on the national ...

Nanjing Liuhe Urban Pipeline Bridge Squadron: Carry out a centralized rectification action to clean up small advertisements

In order to further improve the level of refined management in the jurisdiction an...