These wastes can "turn waste into treasure" in engineering construction?Intersection

Author:Institute of Physics of the Ch Time:2022.09.24

""

While the continuous development of human society and the continuous enrichment of industrial and agricultural products, a large number of industrial and agricultural wastes are constantly producing. These wastes not only occupy a large amount of land, but also cause severe pollution to the ecological environment. If you want to develop sustainable, you must find the right destination for them and make them "into waste into treasure." The construction of the project plays an important role in it. What are the wastes? How did they be used? Let's find out together.

Coal ash

Flyash

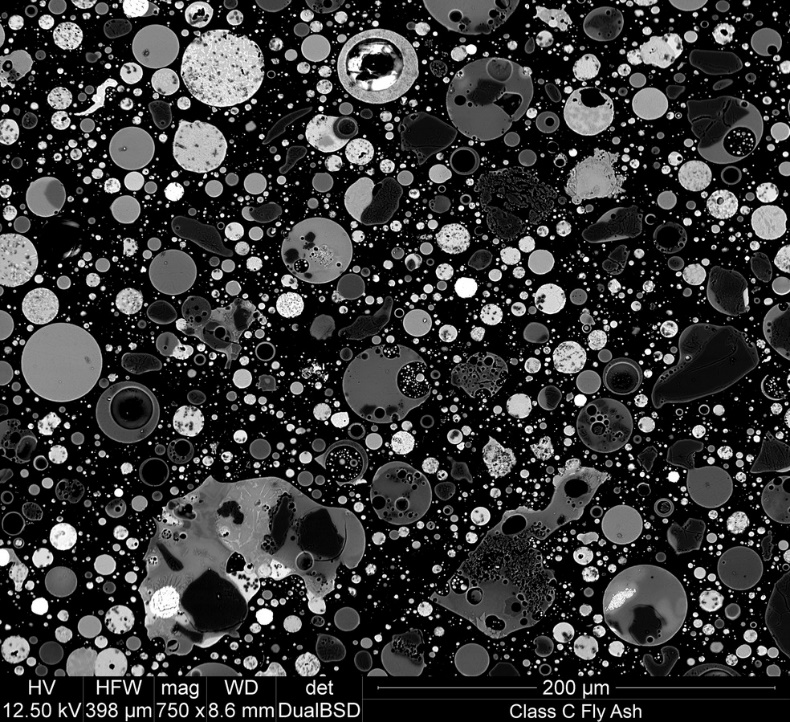

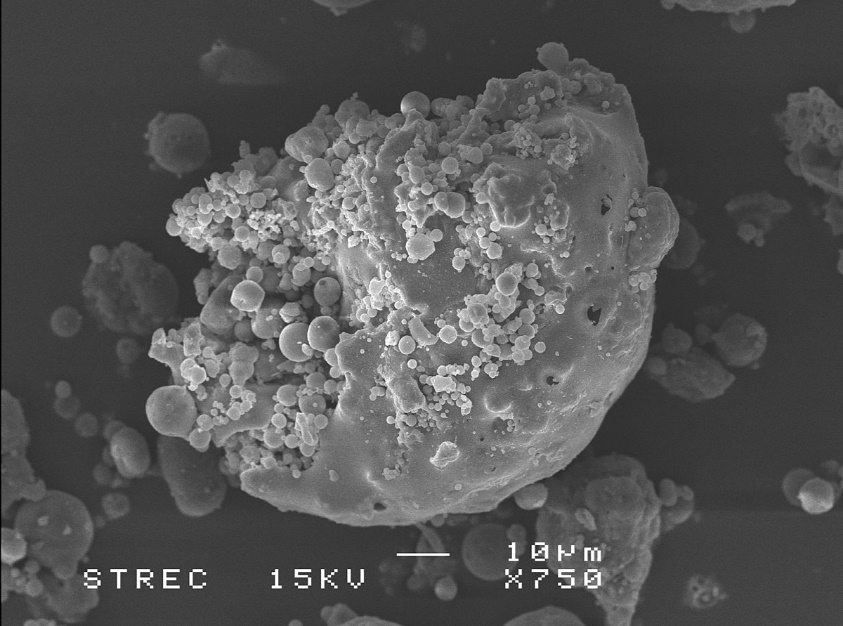

Flyash (Flyash) is a small gray grain produced during the combustion of fuel (generally coal). It is generally gray -white to gray -black, and is also called "fly ash" or "tobacco ash". Its main ingredients are silicon oxide (SIO₂), alumina (al₂o ₃) and iron oxide (Fe2O3), and also contain a certain amount of calcium oxide (CAO) and magnesium oxide (MGO), and other substances. The size of the particles is generally 0.5 ~ 200 μm. No. Because of the surface tension after the cooling process, its shape is generally ball -shaped. Some of them become honeycomb -shaped combined particles because they collide with each other.

Figure 1 The flour ash particles under the microscope are spherical. (Image source: wikimedia Commons)

Figure 2 The flour ash particles are honeycomb -shaped due to collision and adhesion during the formation process. (Image source: wikimedia Commons)

As the world's largest coal producer and consumer country, my country produces about 80,000 to 900 million tons each year, while the current utilization rate is only about 70%. A large amount of flour ash has accumulated around the power plant for a long time, entering the atmosphere and water, which causes serious harm to the ecological environment and human health [1]. As of 2021, the cumulative accumulation of flour and coal ash in my country has reached 3.1 billion tons, which has increased its efforts and is imminent.

Figure 3 The flour ash enters the atmosphere, causing air pollution. (Image source: wikimedia Commons)

In fact, as the product of fuel burning, the flour ash itself has a lot of excellent properties and can be used in various aspects such as industrial and agricultural production and engineering construction. Its loose pores are larger than the surface area, so they have strong adsorption capacity and strong insulation resistance. For example, the coal -to -coal ash bricks made of flour ash, light quality, high strength, high strength, insulation and refractory resistance, which is an excellent material for construction projects. The use of flour ash as a base and building fillers, not only good filling, but also high strength.

Figure 4 Mans and coal ash tile

Powder ash can be used as additives such as cement, concrete and other materials to improve material performance. A variety of active substances contained in it, gel substances are generated after mixing with cement and lime, which greatly improves the strength and anti -penetration performance of the material. Adding flour ash to the concrete can reduce the amount of water mixing concrete, significantly reduce the heat insulation of the concrete during the solidification process, thereby avoiding the production of cracks. This is particularly suitable for the construction of large -volume concrete projects. For example, the world -famous Three Gorges Dam project consumes more than 1.7 million tons of flour ash, which makes the dam to solid the gold soup, and there is almost no cracking after construction.

Figure 5 The Three Gorges Project uses a large amount of flour ash to effectively prevent cracking during the cooling process of concrete cooling. (Image source: wikimedia Commons)

Phosphopide

Phosphogypsum/Ardealite

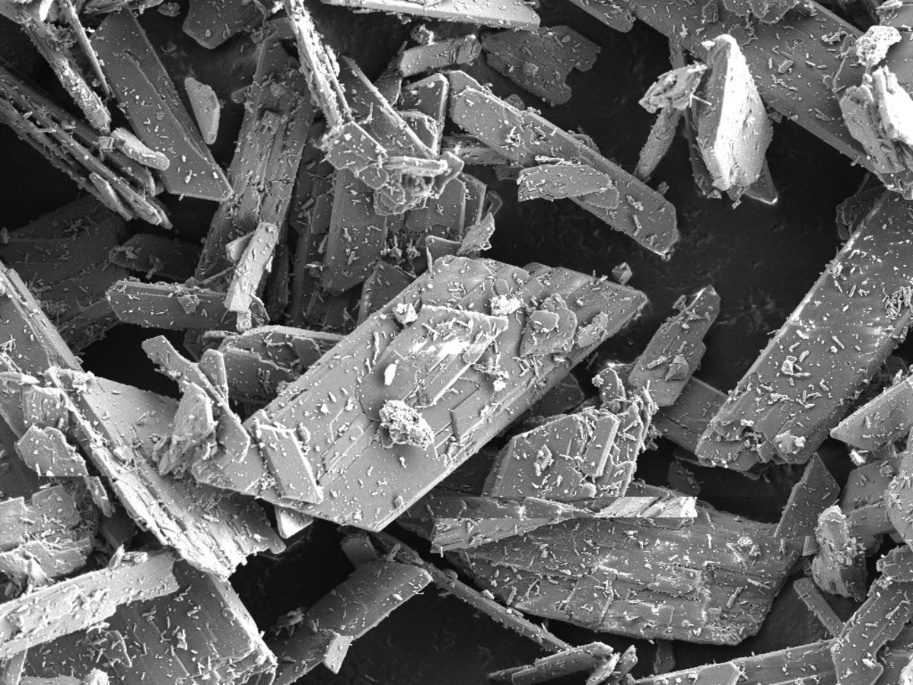

Phosphorum is a by -product of the phosphate process of wetting process. It is gray -white to gray -black powder solid particles. Its main component is calcium sulfate (CASO4 · 2H2O), and also contains a large amount of harmful substances such as heavy metal elements, fluorine, organic matter, and radioactive elements.

Figure 6 The main component of phosphide gypsum micro -image is calcium sulfate (CASO4 · 2H2O), mainly plate -shaped crystals. (Image source: wikimedia Commons)

The output of phosphide gypsum is large, and every 1 ton of phosphate produces 4 to 6 tons of phospholoside, and my country's annual output exceeds 78 million tons. However, the utilization rate is low, my country's comprehensive utilization rate is only about 40%, and the stacking volume is as high as 800 million tons. As a solid waste, a large amount of stacking will cause a series of problems such as heavy metal pollution, nutritional water, and air pollution. The accumulated phospholosypsum can reach tens of meters in height, and there is also the risk of landslide disaster at any time.

Figure 7 Near Fort Meade, Phosphorol plaster piled up outside the Fort Meade. (Image source: wikimedia Commons)

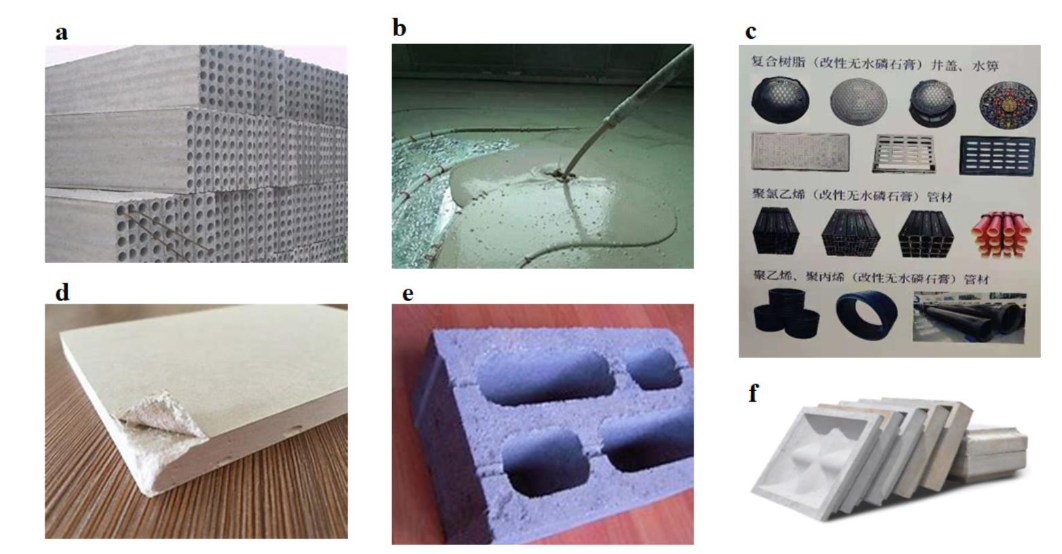

Phosphor gypsum contains a large amount of impurities, which need to be purified before use to reduce its danger. In terms of use, phosphopide is currently mainly used in the field of construction engineering. For example, phosphide gypsum can replace natural gypsum as a cement slowing agent, delay cement solidification, and strive for concrete mixing and pouring; it can be used to produce building materials such as powder brush gypsum, gypsum plates and other building materials. Slope protection et al. [2].

Figure 8 2015-2020 The survival and use of phospholosypsum in my country and its use. It can be seen that most phosphopide is applied to the engineering field. (Picture source: Literature [2])

Figure 9 Various building materials made by phospholosypsum: (A) Phosphorum gypsum buildings; (b) Phosphor gypsum foundation from flowing mortar; (C) fillers of phospholosypsum for polymer materials; Board; (E) Phosphor gypsum building block; (F) Gypsum mold box (phospholoscentry). (Image source: Literature [3]) Figure 10 Mix the phospholosifying with the soil for the slope engineering. (Picture source: Photo by the author)

Coal

Coal Refuse/COAL WASTE

Coal vermiculite is a kind of accompanying mineral of coal, which produces the process of mining and washing and washing. Compared with ordinary coal, coal gangsters have the characteristics of low carbon content, low thermal value, and hard texture. Generally stored in a stacked manner. At present, my country's coal piles have reached 7 billion tons. A large amount of accumulation will cause disasters such as spontaneous combustion, sour rain, underground penetration, silt river channel, photochemical smoke, and mudslides.

Figure 11 is located in the coal pile of coal piles west of Trevorton (Pennsylvania). (Picture source: wiki media commons)

As a kind of rock accompanied by coal seams in coal mining, coal gangue also contains a certain amount of combustible charcoal and metal and non -metallic minerals. By crushing coal vermiculite into small particles, coal can be recycled and mineral materials can be recovered. The combustion calories of coal vermiculite can also be generated.

Figure 12 Shanxi Jinhua Palace Coal Mine, people are selecting the useful coal -fired in coal stones. (Image source: wikimedia Commons)

In terms of construction engineering, coal vermiculite is widely used. Coal gangsters themselves are a stone, so it can be used as a concrete aggregate for brick -making and production hollow blocks. In the process of using coal vermiculite to burn bricks, coal gangsters themselves can burn and heat, so it can save fuel. In addition, coal vermiculite can also be used as fillers for coal mines to prevent the collapse of air, as well as backfill for roadbed backfills.

Figure 13 coal gangue brick (picture source: literature [3])

Figure 14 Fill the roadbed with coal vermiculite. (Picture source: Literature [4])

slag

Slag

The slag is a silicate of impurities such as silicon dioxide (SIO2), alumina (Al2O3) such as silicon (SIO2), alumina (Al2O3) in iron ore during the iron refining process of the iron ore. After the melting material, after the cold treatment, the porous non -fixed structure is presented. Depending on the position of the ore, about 0.5 ~ 0.9 tons of slag is generated for each ton of steel. At present, my country ’s annual metal smelting has a slag of about 735 million tons, but the utilization rate is only about 69%, and the slag reserves exceed 5 billion tons [5].

Figure 15 and 16 slag cooled in the melting, showing a porous structure with different forms. (Image source: wikimedia Commons)

FIG. 17 The smelting plant poured the molten dregs in the garbage dump. (Image source: wikimedia Commons)

In the field of engineering, slag is widely used. The blasting granulated blast-family stch (GGBS) that is made of slag crushed slag, which can be used as additives for cement and concrete. Adding slag powder to cement and concrete can not only reduce the amount of cement dosage saving resources, but also improve its strength and durability. However, there are also defects with low early intensity. (Wiki)

Figure 18 The slag micro powder produced after grinding and so on. It is widely used in the building. (Image source: wikimedia Commons)

Add gel material to the slag to suppress the slag brick of production, high strength, is a good building material, which has been used for more than 100 years; the slag cotton cotton cotton made by melting, high -speed centrifugal or blowing is light, light quality, resistant to resistance, resistant to resistance, resistant to resistance Corrosion, freezing fire prevention, is excellent masonry, sound insulation, and insulation materials.

Figure 19 The outskirts of Hasselfors (SWEDEN), Sweden, were built in an abandoned house in the first 20th century and used bricks made of blue slag in nearby steel plants. (Image source: wikimedia Commons)

Figure 20 Mineral cotton made of slag. (Image source: wikimedia Commons)

In addition, the application of blast furnace slag is still pioneering. Because the slag contains a large amount of silicate minerals, it produces microcrystalline glass, wear -resistant floor materials and porous ceramic materials with slag, which has a wide range of prospects [5].

High molecular waste

Polymer Waste

High molecular waste is a complicated structure, composed of high -molecular organic matter, and typical: waste plastic, waste rubber, waste paint ink, asphalt, animal and plant fiber and protein, fat, etc. The large accumulation of these wastes will cause severe pollution to the environment. In the field of engineering, they also have many uses.

Plastic plastic (Plastic)

At present, plastic pollution has become the world's second largest focus environment after climate change. The characteristics of large output and difficulty degradation have greatly affected the ecological environment. According to statistics from the United Nations Administration of Environmental Planning from 2021, from 1950-2017, a total of about 9.2 billion tons of plastics were produced around the world. By 2050, the estimated output will increase to 34 billion tons, and an average of 300 million tons of waste plastics will be generated per year. Figure 21 On the ACCRA Beach (Ghana) in Ghana, plastic garbage is covered. (Image source: wikimedia Commons)

A large amount of waste plastic can also become waste into treasure if it is handled properly. Using waste plastic, you can produce regenerative plastic, produce fuel, synthetic ammonia, adhesive and other chemical products. The waste plastic itself can also be used as fuel. In the field of engineering, waste plastic can also be used to produce building materials. For example, industrial waste PVC can be used to produce lightweight concrete. Waste foam plastic can be made into cement water reducing agents. Plastic pillow wood is used for railway laying [7].

Figure 22 Shopping bags made of recycled plastic. (Picture source: wikipedia)

Figure 23 Pillow wood made with abandoned plastic. (Picture source: wikipedia)

Rubber (Rubber)

my country is a large country of rubber utilization, and rubber consumption accounts for about 30%of the world's total consumption, and has ranked first in the world for many years. While using rubber, a large amount of waste rubber is also generated, and 70%of the total amount of waste rubber comes from waste tires. In 2020, my country's waste tire output was 13.9 million tons. A large amount of waste rubber is accumulated together, not only occupying land, polluting the environment, but also the risk of inducing fires [8].

Figure 24 The waste tires accumulated like mountains. (Image source: wikimedia Commons)

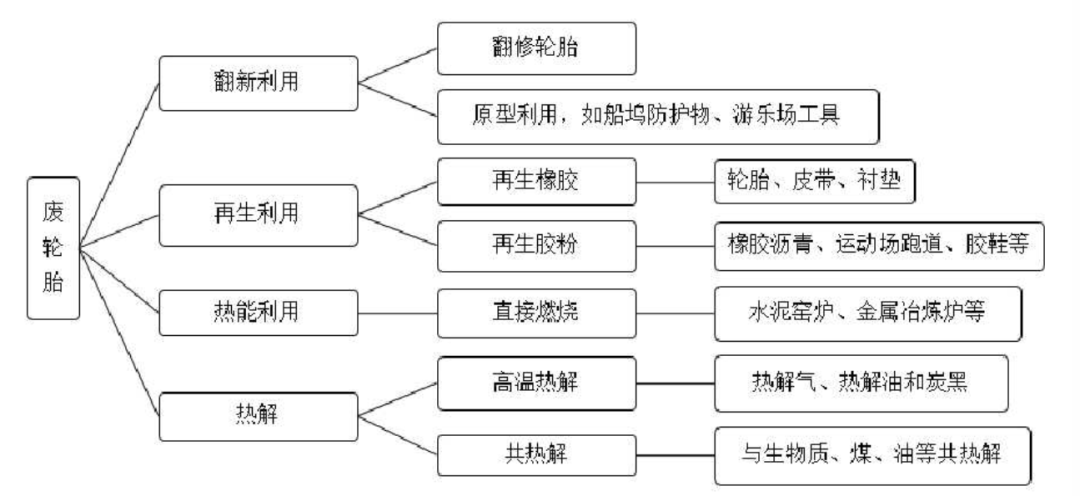

Like waste plastic, the cycle of rubber is also used for renovation or processing, renewing, production regeneration rubber, as a fuel, and production chemical products after decomposition. In terms of engineering, the characteristics of the waste rubber itself are elastic and stable, and the waste rubber is simply processed and used to be used in engineering construction. For example, the rubber particles processed by waste tires can be used as a buffer of artificial lawn or filled in the subgrade; the rubber powder made of rubber and grinding can be used to produce regenerative rubber and waterproof coils. ; In terms of slope protection, the waste tires are used for the fixation of the soil of the slope and the buffer of the falling stone roller, which has good results.

Figure 25 The main cycle utilization method of waste tires. (Picture source: Literature [9])

Fig

Figure 27 Tire for the slope, solid earth planting (picture source: literature [10])

Figure 28 uses waste tires as the cache in front of the wall to cushion the ability to roll the rock and reduce damage. (Picture source: Literature [14])

Natural fiber (natural fibers)

Plant fibers such as straw, banana, shredded coconut, bamboo, palm, etc., are produced in a large number of agricultural production in each year, and their disposal often becomes a headache. The incineration treatment often used in traditional agriculture will produce a large amount of smoke pollution air; if the filling is used, it will not only occupy the land, but also the risk of fire. In fact, natural plant fibers have huge utilization value and are widely used in various fields.

Figure 29 The straw on the farm is full of straw (picture source: wikipedia)

Figure 30 Coconut fiber and its products (picture source: wikipedia)

Using natural plant fibers, a series of products can be produced. For example, fibers such as straw can be used for production of feed after microbial decomposition; after suppression of carbonization, biomass charcoal can be produced as fuel; it is not necessary to say Experience [11].

Figure 31 Paper made of banana fiber (processed by banana stems). (Image source: wikipedia commons)

In terms of engineering, natural fibers instead of artificial fiber as a tendon material have been widely used. Adding fiber such as wheat straw to the soil can greatly increase the strength of the soil and does not cause any pollution to the soil; adding plant fibers in cement and concrete and lime soil has the same effect [12]. These achievements are widely used in the construction of roads, foundations, bridges and tunnels.

Figure 32 Add fiber soil with wheat straw (picture source: literature [13])

references

References

[1] Huang Qian. Analysis of the status quo and development prospects at home and abroad [J]. China Wan Mine Salt, 2011, 42 (04): 41-43.

[2] Zhang Jun, Xie Weimin, Dong Xiongbo, etc. The comprehensive utilization of phosphopide materialized research progress [J]. Materials Herald: 1-24.

[3] Shangdong. Ecological appropriate technical research based on the southern Hebei region architecture [D/OL]. Hebei University of Engineering, 2015 [2022-09-02]. Https://oversea.cnki.net/kcms/detail/detail .aspx?dbcode=CMFDdbname=CMFD201601filename=1015375619.nhuniplatform=OVERSEAv=i5vp-A4WlXG9Ch47f4kN5aOI22C-Ifwlxb50Fcq37HfRC1ydQ_Ag1CqKJFPdZjNc.[4]狄升贯. 高速公路煤矸石路基路用性能研究[D/OL]. 长安大学, 2008[2022- 09-02]. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CMFDdbname=CMFD2009filename=2009066170.nhuniplatform=NZKPTv=s5J_2Fx0_Oul9BO3leenmKDRpPLm5ceV1btZykkG0YDzXaGDOhbWLawXKkZYFjy3.

[5] Yang Ting, He Xi. Research status and outlook for the use of scum resources of blast furnace slag [J]. China Environmental Protection Industry, 2020 (03): 65-68.

[6] Yu Chengfeng. China's waste plastic recycling and utilization in the world [j]. Environment, 2022 (06): 59-61.

[7] Qian Bozhang, Zhu Jianfang. The current status and technological progress of waste plastic recycling [J]. Chemical industry, 2008, 26 (12): 33-40.

[8] Tian Xiaolong, Guo Lei, Wang Kongshuo, et al., Waste Tire Cycle and Resource Use Development Status [J]. Chinese Materials Progress, 2022, 41 (01): 22-29+66-67.

[9] Research on heavy oil and waste tire powder treatment and co-refining process [eb/ol]. [2022-09-02]. Https://chn.overa.cnki.net/kream2/reView?platform=OverseapRoduct= CMFDfilename=1021667130.nhtablename=cmfd202102type=DISSERTATIONscope=trialcflag=overlaydflag=pages=language=chsinvoice=kxBzzG%2Bc8jaw2RdGbcMH4LOG92ZJJuWcqo3URsP2s6m%2FtOu3LQ2XrdMTH5SgSo1durghVLE7JXg7BIqdJZVVotHiv9rhxHhoI7D0S8DMl2uSIieuAQxJVf6ykJ7qDWbDz2dc2oxFwwZSpk81TEeP3mrsppfaSGl%2FstJaQIKu9V4%3Dtrial=nonce=3145298BFE4D4919AC923A97C0B1503A.

[10] The application of Zeng Zhonghe. Waste tires The application of soil planting grass in weathered rocky slopes [J]. Construction technology, 2019 (S1 VO 48): 1214-1216.

[11] Zhang Chenglong. The current status and prospects of the resource use of agricultural waste [J]. Environmental protection, 2002 (01): 22-23.

[12] Research and application of plant fiber in different actual engineering [J]. Sichuan Building Materials, 2018, 44 (01): 116+130.

[13] Chen Jia. Research on pressure performance of modified soil material and adobe masonry [D/OL]. Xinjiang University, 2009 [2022-09-04]. Https://kns.cnki.net/kcms /detail/detail.aspx?dbcode=cmfddbname=cmfd2010filename=2009196181.nhunipLatform=nzkptv=6vnerih9gpjqnfbmz2jdoney5fvny

[14] Editor -in -chief of Yin Yueping, typical landslides in China [M], Beijing: China Land Publishing House, 2007.12: 14

Beautiful editor: Xu Hongxi

School pair: Jiang Xuezheng Liu Qi County

Reprinted content only represents the author's point of view

Does not represent the position of the Institute of Physics of the Chinese Academy of Sciences

If you need to reprint, please contact the original public account

Source: Geological Earth Institute of the Chinese Academy of Sciences

Edit: Shepherd

- END -

Check 23.78 tons of fireworks and firecrackers

Recently, Meishan Customs, which belongs to Ningbo Customs, was manually inspec...

Don't believe it, ice cream is better than ice cream

To ask how to distinguish ice cream and ice cream, everyone has their own tips:Som...