33 million "planting trees" a year! This construction industry has gradually become a "carbon reduction household"

Author:Hubei Daily Time:2022.09.23

The industrial waste replacement of cement in Wuhan alone can reduce carbon dioxide emissions by nearly 600,000 tons, which is equivalent to planting 33 million trees

The pre -mixed concrete industry is expected to become a large carbon emission reduction household

Hubei Daily All Media Reporter Zhang Aihu

The pre -mixed concrete industry that is rarely received in normal times is expected to become a large carbon emission reduction household in the construction industry.

On September 22, the province's pre -mixed concrete industry's high -quality development on -site observation meeting was held in Yellowstone, the theme was "planning and leading, green concrete, innovative development".

Pre -mixing concrete refers to components such as cement, collective material, water, and outer agents and mixtures mixed as needed as needed. According to a certain percentage, it is sold after the centralized mixing station (factory). Settlement compounds transported to the location within the specified time.

Zheng Tao, chairman of China Construction Commodity Concrete Co., Ltd., introduced in a speech that Wuhan produced 45 million cubic meters of concrete a year in Wuhan, and calculated based on the average of 50 kg of coal ash per square of concrete, which is equivalent to replacing cement 120 with once industrial waste. The remaining 10,000 tons, a reduction of nearly 600,000 tons of carbon dioxide emissions, which is about 33 million trees. These green plants are distributed, which can cover the area of Sicai Mountain in 3 Huangshi City.

As we all know, the construction industry is a large carbon emission household, accounting for about 40%of carbon emissions in the whole society. Developing green buildings and reducing carbon emissions is imperative.

Zheng Tao said that the concrete industry has always been considered a low -end industry with low standardization, high pollution, and poor dirty. This stereotyped image has caused great trouble for the investment, financing, personnel introduction, and task acceptance of concrete companies, and restrained the development of the industry. But few people realize that the concrete industry is also a "big household" absorbing and digestive carbon emissions. It is precisely because of the existence of the commercial industry that a large number of abandoned industrial waste and tail materials that constitute a huge environmental safety risk, such as flour ash, water residue, iron tail mine, phosphorus slag, saw mud saw powder, etc., etc. Can be re -incorporated into the circular economy.

As the chairman of the provincial pre -mixed concrete association, China Construction Merchants Company also explores a new method of standardization of product, explores a new path of green development, and achieves fruitful results: 16 pre -mixing plants achieve solid waste "zero clearance", which has reduced solids in total, and cumulative solids will be reduced. Waste 400,000 tons, which is equivalent to reducing a large -scale solid -waste mountain with a height of 16 floors. Through a mixer truck and forklift, "oil change electricity" can be achieved. The carbon dioxide absorption of a big tree one year.

The day before the meeting, Huangshi Zhongdu Concrete Co., Ltd. ushered in many observants. At the entrance of the factory, the spray gun is cleaning the transportation vehicle; in the large factory building, the ground is clean, and the slag waste liquid in production is recovered and used to "eat dry and squeeze". Everyone praised its green, environmentally friendly, clean, and efficient production.

Considering factors such as urban development and traffic control, Huangshi Zhongdu Concrete Co., Ltd. has invested a new "Green Environmental Protection Fair", and the Nissan capacity reaches more than 10,000 square meters. After the company's 6 -party host is put into production, it can gradually reduce the time of pouring concrete. At present, a 1000 -square project, the traditional concrete mixing station takes at least seven or eight hours, and the company is poured for 2 hours to complete.

Huangshi Zhongdu Concrete Co., Ltd. and manufacturers innovatively developed the "sinking three -dimensional material warehouse" and "intelligent material supply system" to ensure the distribution of aggregate and apply for a national patent. In the 50,000 -ton three -dimensional material warehouse, the aggregate, through 120 measuring instruments and 60 measuring buckets, rely on the aggregate self -weight, and quickly transport the 6 horizontal belt at the bottom of the three -dimensional warehouse to the main belt to ensure the accurate measurement of the aggregate. With real -time supply, the overall production efficiency is 120%higher than that of traditional concrete companies, and unit energy consumption is reduced by 27%.

Relevant parties said that through advanced models, we must also see gap and development potential. From the perspective of the province, the production capacity utilization rate of the commercial industry needs to be improved: At present, there are 834 pre -mixed concrete enterprises in the province, with about 1,400 production lines, an annual design production capacity of about 380 million cubic meters, and the cumulative supply of concrete in 2021 Mi, the average capacity utilization rate of enterprises is about 40%. In terms of green production, the province's proportion of green production logo companies is only 27.5%.

The relevant person in charge of the Hubei Provincial Department of Housing and Construction pointed out that it will take the initiative to take the initiative to optimize industrial layout, standardize quality behavior, strengthen green production, promote industry intelligence, and promote industry intelligence around high -quality, high -level safety, green, digital intelligence, digital intelligence, digital intelligence, digital intelligence, digital intelligence, digital intelligence, digital intelligence, digital intelligence, digital intelligence, digital intelligence, digital intelligence, and scientific and technological innovation. Development, improvement of supervision efficiency, attach importance to the development and application of rural areas, and promote the high -quality development of the pre -mixed concrete industry in the province.

The Hubei Daily client, paying attention to the major events of Hubei and the world, not only pushing the authoritative policies for users, fresh hot information, and practical convenience information, but also launched a series of features such as reading newspapers, newspapers, learning, online interactives.

- END -

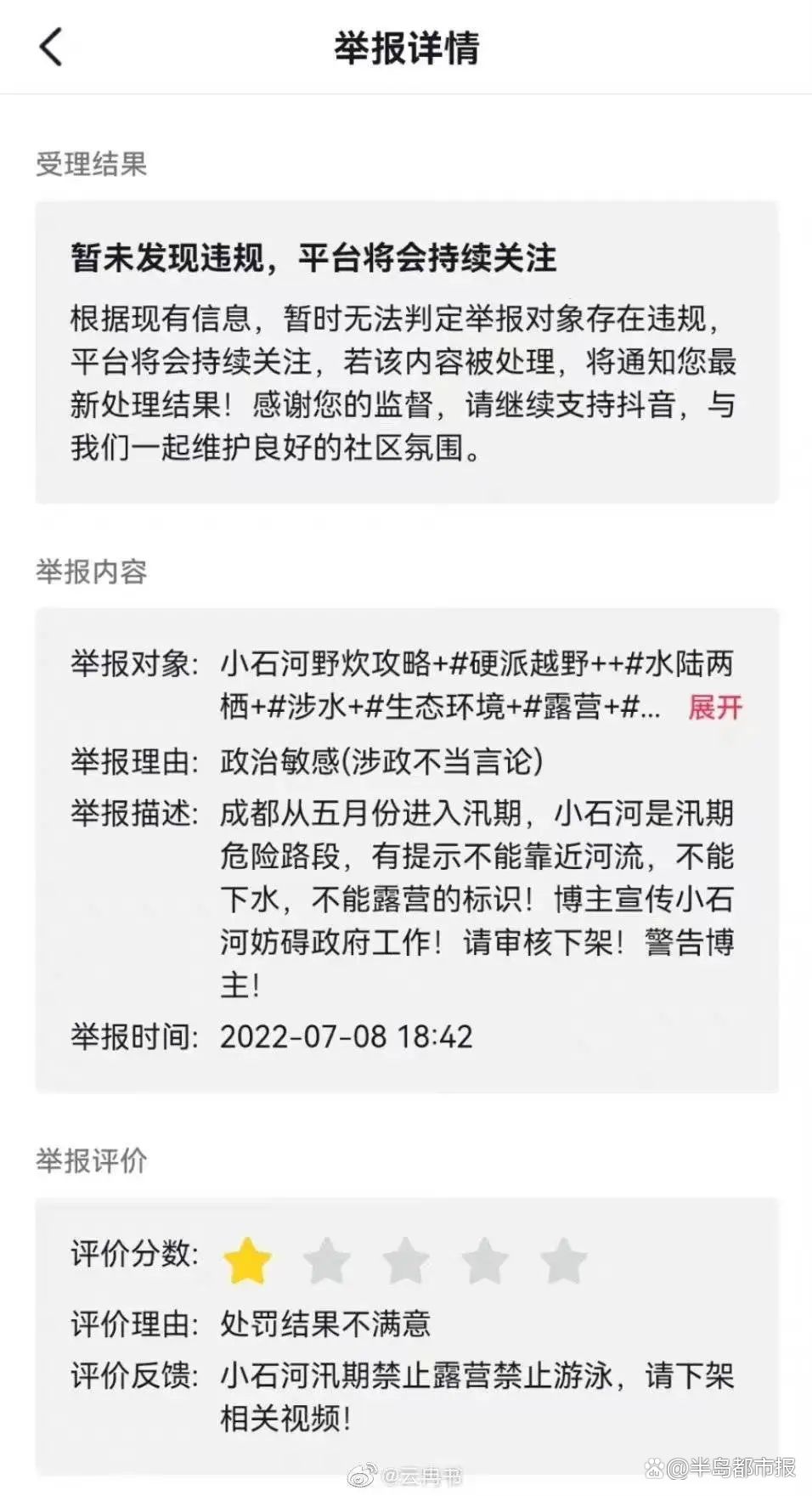

Feading nature and cherishing life, wild "net celebrities" must not "plant grass" blindly

Yesterday, the news of the sudden floods in the Longconggou area of Pengzhou a...

"Flying to the Luding Bridge -like rescue"!The first -line special police talk about live details

September 5thA magnitude 6.8 earthquake occurred in Luding County, Ganzi Prefectur...