The "dialogue" of the Chengdu -Chongqing Railway and the Zhengyu High -speed Railway 70 years

Author:Listening to FM Time:2022.06.20

Today, the high -expected Zhengyu high -speed rail was officially opened.

At this time, the first railway built by the New China, which was opened to traffic in 1952, the Chengdu -Chongqing Railway, for a full 70 years.

In 70 years, from the Puchai Railway at a speed of 450 kilometers per hour, to a high -speed railway with a speed of 350 kilometers per hour, the Chinese railway construction has achieved a large leap, and China's high -speed rail mileage has ranked first in the world. This magnificent history of railway development can be condensed in a "dialogue" of the Zhengyu high -speed railway and the Chengdu -Chongqing railway across time and space.

The Chengdu -Chongqing Railway Cement was imported by import, and I dare not open it at all.

A Pengxi River Bridge of Zhengyu high -speed rail consumed 20,000 tons of cement

Less than 10 seconds! The train galloped on the Bridge of the Pengxi River in Zhengyu's high -speed rail.

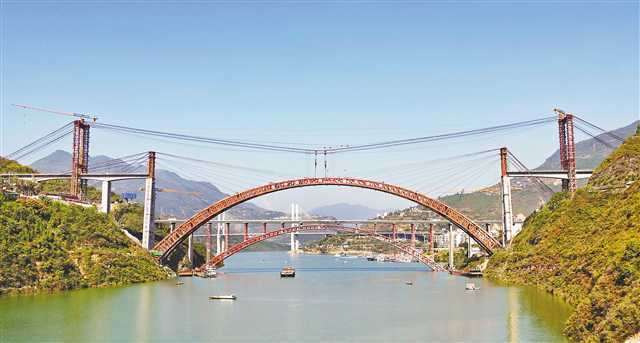

Above the Pengxi River in the Yangtze River, the bridge rose in the air and stunned things, and it was spectacular under the blue sky and white clouds.

The Pengxi River multi -line bridge located on Yunyang is connected to Yunyang Station of Zhengyu High -speed Railway at one end, and the other end connects the Zhengyu high -speed railway Wanzhou people and tunnels. It not only has the largest steel coffin on the entire line -equivalent to more than 10 floors height, weighs more than 2,000 tons, but also has the first deep rail deep railway pile -deeper into the river bed for 55 meters.

Zhengyu Gao Railway Meixi River Double Line Steel Gonghelong. (Data Picture) Photo Conferry of the Chengdu Railway Bureau

Why is this bridge so powerful? Peng Yangpin, deputy chief of the 9th bidding project of the Chongqing section of China Railway 11th Bureau, said that it mainly depends on a "reinforced iron bone" -the bridge consumed 18,000 tons of steel and 20,000 tons of cement!

Steel and concrete are the main materials for railway construction, especially bridges and tunnels. However, when the Chongqing Railway was built 70 years ago, the cement was still rare. At that time, most of the cement in Chongqing came from Shanghai, Wuhan and other places, and it was necessary to use ships to transport through the Yangtze River.

In order to ensure the cement supply of the Chengdu -Chongqing Railway, on the one hand, relevant departments purchased from the middle and lower reaches of the Yangtze River through shipping; on the other hand, the production of Chongqing Cement Plant was restored.

The Chongqing Cement Plant was established in 1936. It is located on the Agen Creek on the south bank. It was the first cement plant in the southwest. It had been discontinued before liberation. After restoring production, the products produced by this cement plant are specifically for the Chengdu -Chongqing Railway. There are special supervision from feeding to factory transportation. After a few years, the Chongqing Cement Plant provided 50,000 tons of cement for the Chengdu -Chongqing Railway, and also won a prize.

However, due to the limited supply, the cement dare not be open at all. Building the Chengyu Railway also requires local mining stone as a substitute for cement. There are 28 new tunnels on this railway, all of which are stone -building; tunnel arch ring, 23 are stone arch. The entire railway bridge culvert project accounts for more than 60%, only 8.6%of the concrete, and 827 stone arch bridges on the entire line.

The Chengdu -Chongqing Railway raised a fibrous rattan rod as a torch, holding the steel buns little by little

Zhengyu high -speed rail smart three -arm rock -cutting trimmed car drilling cloth to set up artillery eyes

"The sky is not bright, and the army name has echoed in the valley. Without a lamp, the fiber vine rods with tung oil as a torch are held; if there is no mechanical, just hold the steel hoe and smash it little by little ..." Chengdu -Chongqing Railway builder Sun Yizheng described the labor scene when he described the construction of the Chongqing railway that year.

Sun Yizheng told reporters that due to the lack of technology and less equipment, in order to improve efficiency, save labor, and reduce tool wear, explosives have become essential materials.

However, at that time, explosives were also scarce, and they were only used when they encountered large rocks, or the terrain could not be used for artificial excavation. Whenever the children living nearby have to fire at the construction site, they will meet to see the excitement, and feel stronger than the New Year.

In order to use as little explosives to repair more ways, the builders also came up with a lot of new tricks. For example, the single -person steel tincture method has increased the efficacy of the blasting cannon eye workers more than doubled; the artillery method is overwhelmed, which can save a lot of explosives.

In Zhongyi Town, Ziyang City, Sichuan Province, the train was driving on the Wang Erxi Bridge of Chengdu -Chongqing Railway. Wang Erxi Bridge was once the longest railway stone arch bridge in the country. (Photo on June 27, 2019) Reporter Long Fan Photo/Visual Chongqing

Nevertheless, the artificial excavation of the cannon eyes and detonation are easy to cause casualties. Even in the links that do not use explosives, the risks brought by tunnel collapse and water seepage are great. According to the "Summary of the Chengdu -Chongqing Railway Project", the Maidianzi Tunnel supports the falling stone and the cypress tunnel ceiling, etc. The construction of 14 tunnels such as cypresses alone, 15 people were killed, and 69 were seriously injured.

The builders of the Chengdu -Chongqing Railway may be difficult to imagine that the Zhengyu High -speed Railway, which was opened to traffic 70 years later, can use robotic arms to open eyes and fill explosives during the construction process.

According to Zhu Jianguo, the Civil Engineering Chief Worker of the Little Three Gorges Tunnel of the China Railway Tunnel Bureau, the project they are located have customized two smart three -arm rock -loving platforms. This kind of construction machinery has three long arms, which automatically retract according to the geological conditions encountered, and the positioning is accurate. The rear refers to where to set up artillery eyes. In 3 hours, it can automatically drill a row of rows of cannon eyes with uniform lines and smooth lines on the supporting sub -surface of about 200 square meters.

In the construction of the Three Gorges Tunnel, in addition to advanced equipment such as intelligent three -arm rock -cutting car, there are also wet spray units, hydraulic self -moved stabs, automatic pouring template vehicles, overall mobile grooves, semi -automatic spray maintenance maintenance Stranging and so on. Relying on these equipment, the construction site can meet more than 10 operating lines to dig at the same time, so that the tunnel can be connected for one year in advance.

Use equipment to replace people, while greatly improving efficiency, the casualties have been reduced to zero. When the Chengdu -Chongqing Railway is blocked by natural landforms, the route hovers along the hillside

Zheng Yu's high -speed rail tailoring straight, basically encountering mountains and caves

More than 90 % of the Zhengyu High -speed Railway Xiangwan Duan is a bridge tunnel, with 91 new bridges and 57 tunnels across the board. In the bridge, the Meixi River Bridge and the Daying River Bridge set the industry in the industry at a speed of 350 kilometers per hour. The Little Three Gorges Tunnel is currently the longest high -speed rail tunnel in Asia. The bridge tunnel of the Chengyu Railway has a short length and a small span. The longest tunnel is only 622 meters.

Facing the barrier of natural landforms, the solution of the Zhengyu high -speed railway is to cut straight. Basically, when the mountains are digging holes and a water frame, it has created a shocking bridge and tunnel ratio. The solution of the Chengdu -Chongqing Railway can only be built on the "exhibition line", that is, the line hovers along the hillside.

After the Chengdu -Chongqing Railway, other railways built by New China also adopted a large number of "exhibition lines". Taking the "exhibition line" of the Guanyin Mountain of Baocheng Railway as an example, the railway enters the Qinling Mountains and circled the roundabout along the Qingjiang River. 3 floors, the height difference is more than 800 meters.

From the "exhibition line" 70 years ago to today's hill digging and watering bridges, behind it is the enhancement of national financial resources and the leap of road construction technology. For example, the third long tunnel of the Zhengyu high -speed rail -about 13.5 kilometers of Fengjie Tunnel is typical of tackling and innovation.

Liu Jianhua, chief engineer of Zhengyu High -speed Railway 6th bidding project, responsible for the project in charge of the project, described the crushing geology of the Fengjie Tunnel with "seeing the wind into powder and making water into mud". "We are like digging holes in tofu," he said.

In July 2017, the excavation of the Fengjie Tunnel was promoted for about 30 meters. Monitoring personnel found that the concrete rupture and lump of the tunnel supporting sub -lining appeared, and the steel arches flexed and deformed to "Z". With the tunnel digging, the width of the cracked width of the top of the cave is up to 20 cm, and the tunnel cave's vaults and walls in the tunnel cave have a large deformation, with a maximum sedimentation of 70 cm.

In order to solve this problem, Liu Jianhua and colleagues explored a set of combination of "VC -type support+retractable arch+two -step four -step construction method+temporary elevation arch" and other combination construction methods. This is equivalent to "tofu" Libu has three rows of uplifting arches to increase tunnel stress and elasticity, while increasing support density. question.

Activated with controllable fences in "Tofu" to support a space. This method not only ensures the safety of construction, but also shortens the construction period by 3 months.

The Chengdu -Chongqing Railway artificial rail, dozens of people sang the name and carried the rails forward

Zhengyu's high -speed rail paving machine easily hangs the rails and accurately falls on the road base

In the Zhengyu high -speed railway Wanzhou storage lot, the straight rails extended to the distance. It is called "EMU Hotel", which provides temporary parking, inspection and maintenance, emergency rescue services such as temporary parking, inspection and maintenance, and emergency rescue.

Du John, deputy manager of the Chongqing section of the Chongqing section of the Chongqing section of the 11th Bureau of China Railway, told reporters that the average rail paved by the Zhengyu high -speed rail weighs 122 tons, and only about 380 kilometers from Wushan to Wushan. Rail.

In order to make the high -speed rail more smooth, after the installation of these rails was installed on the spot, another process -welded, that is, welding the rail into one without leaving the gap. Voice.

Time goes back 70 years ago. When the Chengdu -Chongqing Railway was launched, China could not produce a one -inch rail.

Chongqing Industrial Museum, located in the original area of Chonggang, has a treasure of the town hall -8,000 horsepower steam engines. The first steam engine rolled out of the New China was purchased from Britain by Zhang Zhidong, a representative of the Westernization Movement in the early last century. During the War of Resistance Against Japan, from Yichang to Chongqing, due to the bombardment of the fleet, the imported axis of the important component on the steam engine sank into the bottom of the river. This steam engine was once idle on the side of the Dadukou Yangtze River.

When the construction of the Chongqing railway was built, in order to solve the problem of the rails, the technicians and veteran workers of Chongqing 101 Iron and Steel Factory were brought to good benefits, and invited experts recommended by the Ministry of Industry to come to "consultation". After hard work, by early September 1950, the first 12.5 -meter -long rail in New China was finally rolled.

To this day, China's annual steel production has exceeded 1 billion tons, the world's first steel output for more than 20 consecutive years, and has built the most complete and largest steel industry system in the global industrial chain.

It is difficult to produce steel rails, and it is not easy to pave the rails. Sun Yizheng recalled that at the time, he mainly used manpower to transport. In order to cooperate with the pace, dozens of people need to sing the hoods forward, and the shoulders and backs have deep marks. The fixed rails need to rire the sledgehammer, knocking on the rivet with a hammer and one hammer. Even the cold winter moon, the workers will be sweaty.

In the eyes of the Chengdu -Chongqing Railway builders, the laying of the Zhengyu high -speed rail rail can be described as incredible -the rail panel loading with a riveting rail, and the long truss is extended along the road base, which is equivalent to setting up a on -site built one on the scene. Dragon Gate crane, the rail was hung out, and accurately fell on the road base.

The Zhengyu high -speed rail also pioneered the cross -line launch technology of "walking a single -line paving and double -line". That is, after the first railway line is laid, the rail panel machine does not need to turn back to the station. Instead, it directly laid the rails on the neighboring line. The guide device can automatically guide the long rail, which saves about 40%. 182 million yuan.

Digital reading >>> The difficulty and technological innovation of the construction of the Zhengyu high -speed rail Xiangwan section

350 kilometers

The total length of the northern section of Xiangyang East to Wanzhou is 434 kilometers.

98%

The ratio of Xiangwan section bridge is as high as 98%

33 places

There are 33 places involving or neighboring environmental sensitive areas in the territory of Xiangwan Duan Chongqing, including 11 nature reserves, 5 scenic spots, 9 forest parks, 2 geological parks, 6 water source reserves

18.9 kilometers

The Wushan Little Three Gorges Tunnel is about 18.9 kilometers in length, which is the longest speed of 350 kilometers per hour in Asia

16.57 kilometers

The Wushan Tunnel is 16.57 kilometers in length. It is the second long tunnel of the Chongqing section of the Zhengyu high -speed rail.

340 meters

The full length of the Meixi River Bridge in Fengjie is 688.3 meters, the main span is 340 meters, and the maximum height difference is 200 meters. It is the maximum span of the high -speed railway at a speed of 350 kilometers per hour. The construction of the bridge has obtained 30 domestic patents and 2 overseas patents

282 meters

The Wushan Dinghe Extra Bridge is 372 meters long and 282 meters. It is the maximum span of the high -speed railway in China at a speed of 350 kilometers per hour. The basic form of vertical piles, significantly reduce the excavation of the arch of arch

200 meters

Yunyang Pengxi River Multi -Line Bridge is a continuous rigid structure of 200 meters -arch bridge. The main pier foundation uses steel hanging box cofferdam to be constructed to be the largest cofferdam of the Zhengyu high -speed rail.

4 achievements

Xiangwan Duan Chongqing's construction exploration of 4 aspects: The complex terrain of the database area is 350 kilometers per hour 350 kilometers high -speed railway large -crossing basket arch bridge construction key technologies; Design and construction technology; method of evaluation of the site of the scum field in the canyon area on flood prevention and surrounding environmental impact

Source: Chongqing Daily reporter Yang Yongqin organized

- END -

Yanting County Meteorological Observatory lifted lightning yellow warning signal [III level/heavier]

Yanting County Meteorological Observatory, June 08, 2022, at 16:41 on June 08, 2022, at 13:38 on June 08th, a lightning yellow warning signal at 13:38.

Yongde County Meteorological Observatory lifted the red warning of heavy rain [Class I/Especially se

According to the latest meteorological data analysis, Yongde County Meteorological Station was released at 08:50 on June 8, 2022 to release a heavy rain red warning signal at 05:50 on June 8, 2022.