Uniqlo and ZARA's SPA model comparison

Author:Everyone is a product manager Time:2022.07.21

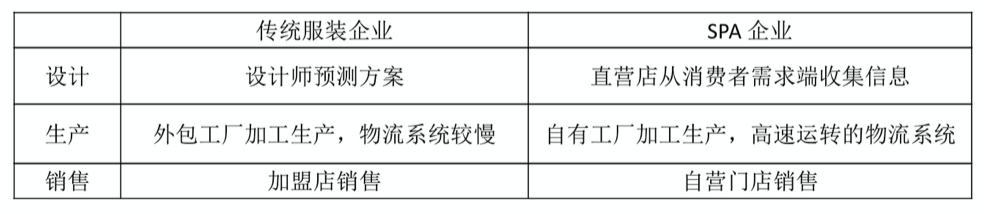

Both companies use the SPA flexible supply chain model. Zara and Uniqlo are successful companies using SPA models. Compared with the overview of the SPA model of ZARA and Uniqlo and their applications, I found that the two companies exist in the development and design of products during the application SPA model, collect purchasing information from the consumer end, fast logistics turnover, fast product update, etc. Advantages, but there are also differences in the specific application SPA model.

1. What is SPA? What are the characteristics

SPA is a supply chain model created by the US GAP company. To this day, the SPA model is no longer limited to the clothing industry, and its application scope has expanded to manufacturing and manufacturers and suppliers.

SPA (Specialty Retailer of Private Label App) refers to a "vertical integrated" business model that the company participates in the whole process. In this model, enterprises need to strictly control the products from all aspects of product planning to sales, reduce the cost of outsourcing, and manage the entire process from the source of the plan to production to the customer's hands. Essence

This model not only shortens the process of the supply chain, but also collects consumer information in all aspects, which further reduces the distance between enterprises and customers. While adjusting the company's strategy and improving product quality, it provides consumers with more comprehensive services.

The traditional clothing industry, from clothing planning, design, production, processing, logistics to the final store sales, it takes 9-12 months. The product development time is long, and the clothing industry is an industry that has been updated frequently. The trend of the market will be eliminated.

The SPA supply chain model has created new development space in the clothing industry. By shortening the product from design to sales, the products are sent to customers faster, so that they occupy an advantage in the clothing market. Compared with traditional clothing companies, the SPA supply chain model has obvious advantages in collecting consumer information, rapid production, and shortening logistics, which can save a certain cost and make the capital flow of enterprises smoother.

It can be seen that effective information systems and rapid reaction supply chains are the key to the success of SPA. By collecting feedback from consumers of store terminals, companies can get information about market demand in time. Therefore, the effective information system is an important support for SPA, and the fast supply chain can shorten the time of product production and logistics and ensure the rapid newness of the product.

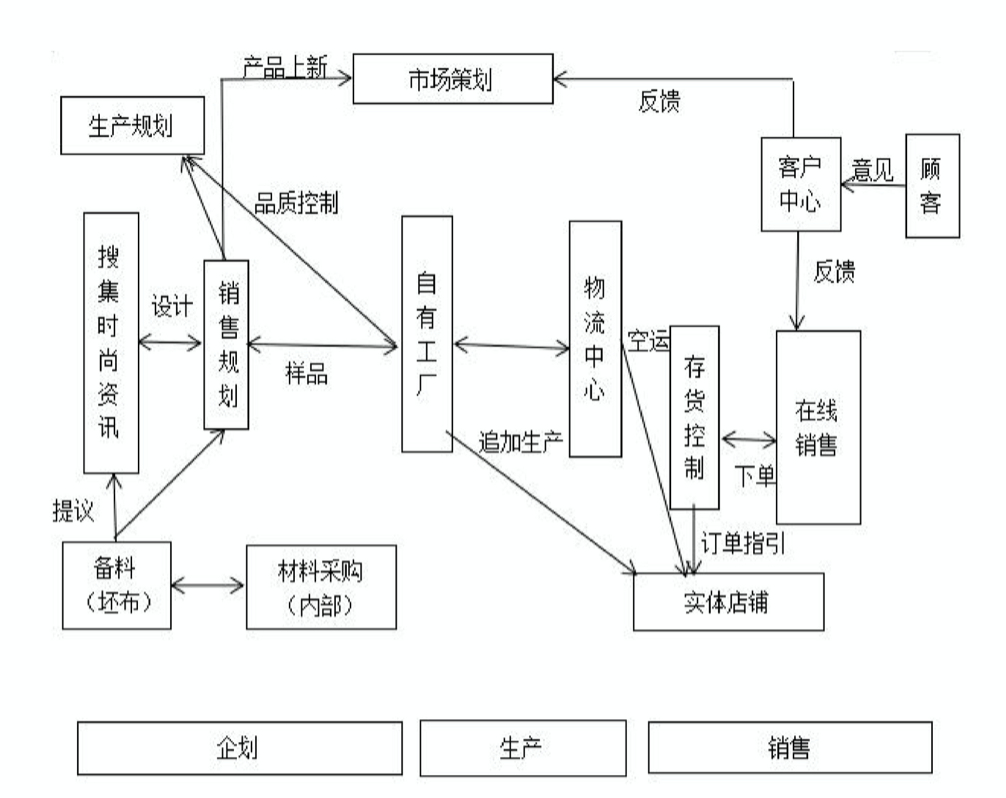

Second, ZARA's SPA mode

ZARA adopts a popular clothing SPA model with high turnover and high gross interest rates. Its supply chain model is divided into three stages: design, production, and sales.

1. Product design stage

ZARA will first collect fashion information from various channels such as stores, fashion shows, fashion magazines, etc., and then the design department will integrate the collected information and predict the trend of clothing. Design scheme research sample.

After the costume version of the clothing is passed, the version of the version is made on the computer software. The well -made version will be sent to the production factory in the form of a CAD diagram, and the factory will be tailored and produced by the factories. After a series of inspections, the production of the samples produced is qualified after passing the review.

The company will determine the specific price of the product and the delivery period based on the cost of the product and the production process, and eventually put the goods into production. During the sales period, Uniqlo will continue to improve the goods according to the customer's response to the goods.

The main target customers of ZARA are professional women, showing "style" through the matching of European popular clothing styles. Its son brand is divided into different ages and lifestyles. For customers of different ages, it provides clothing that meets the needs of various occasions and enriches ZARA's product group.

2. Product production stage

ZARA adopts a small amount of production strategies of multiple, multi -varieties. ZARA is a SPA enterprise from the processing manufacturing industry, so it has a supporting factories with production capacity.

ZARA is located in Barcelona's branch, Kangdier, is responsible for ZARA's fabric production. Before each production, ZARA will book 65%of the raw materials to Conidel. Procurement, but warehouses are generally prepared before adding orders before adding orders. Several major processing plants of ZARA are located in neighboring countries such as Portugal, Spain, and Morocco. Although the production cost is higher than Asia and Southeast Asian countries, due to geographical geography The location is close to ensure the timely delivery of the goods.

After the order is generated, print and dye directly to the fabric to accelerate production efficiency.

In the actual production process, ZARA usually produces 25%of the clothing series in advance for small batches of production. Small batches of production will not only speed up delivery, but also save inventory costs, reduce inventory backlogs, and bring many convenience to enterprise sales.

After the production is completed, it will enter the logistics link. The Zara parent company Inditex consumes a lot of financial resources and material resources. The most advanced logistics centers are built in the surrounding areas of Spain. It is transported to Europe and other countries, and for Asia and the Americas, the air transportation method is used to provide ZARA's rapid transportation convenience and save a lot of time. 3. Product sales stage

Direct stores are the last part of the supply chain system. ZARA chooses to open a store in shopping malls or high rental stations, and reduce production costs through the SPA model to cope with high rent costs. ZARA believes that consumers are not only clothing buyers, their ideas represent the trend of clothing sales. Consumers' choices and suggestions have played a good reference for future clothing design.

ZARA set the sales process to the surroundings. The product with poor sales situation is displayed in the position that the customers are easy to find, and the attention of customers can be attracted by clothing. The new products launched on Monday and Friday were re -displayed, so that every customer who walked into the store had a new feeling, aroused the desire to buy customers.

The mixing display of the store has given customers a good matching suggestion, and also helps the store can realize the desire to match the sales. Therefore, on the one hand, the manager of the ZARA store must order new and replenish products to the headquarters based on the sales plan of the store. On the other hand, it is also necessary to reflect the sales of the store and the customer's purchase suggestion to the headquarters. Design provides reference.

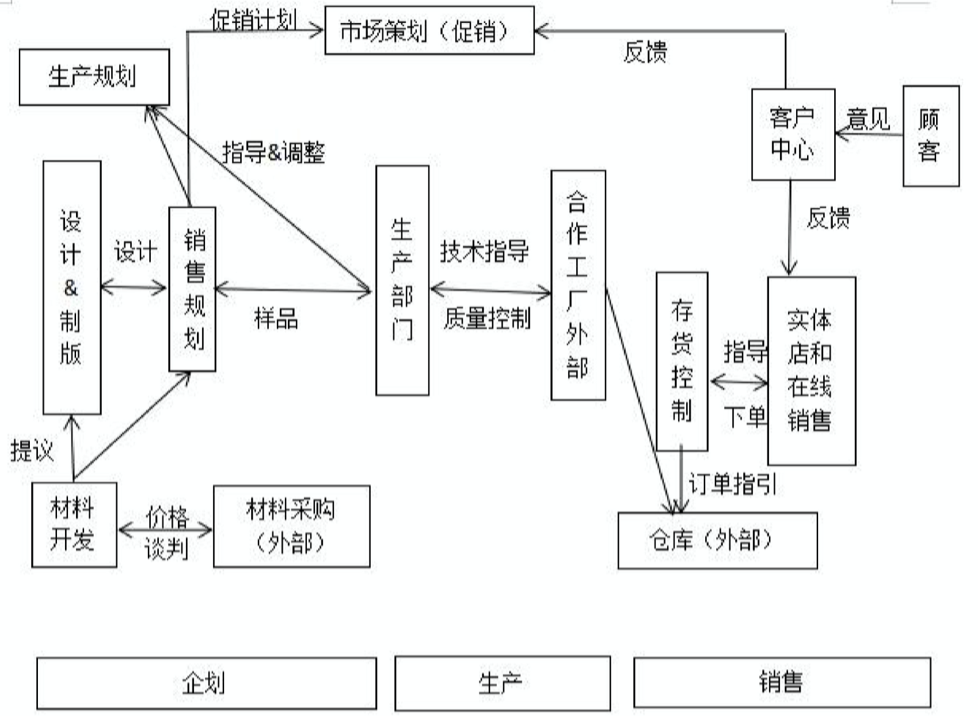

Third, Uniqlo's SPA mode

As a representative company successfully applied to the SPA model, the Uniqlo SPA model is also divided into three stages: product design, product production, and product sales. Unlike other clothing companies, Uniqlo realizes low prices, high quality and high performance in the application SPA model.

1. Product design stage

In terms of product quality and performance, Uniqlo surpass other similar companies. It does not distinguish between the age of the target customer, and the basic casual outfit that most people can wear, is versatile and comfortable. Uniqlo has invested a lot of manpower and material resources in the development and design of fabrics. It is unique to ensure the technological and comfort of the product.

To this end, Dongli, the largest synthetic fiber manufacturer at the time, formulated a long -term strategic cooperation plan and established a long -term strategic cooperation relationship. Uniqlo will provide its store sales data. Essence For example, Underwear products launched by Uniqlo in summer use AIRISM fabrics. It is a fabric developed by Dongli Group in 2012. It has the function of sweating and drying.

In the winter, the Heattech series products are launched, and its fabric depends on the special ultra -fine fiber developed by Dongli Group. This fiber can absorb the trace water steam emitted by the human body and transform the water steam into thermal energy. Therefore Function.

By using four different fiber weaving fabrics, multiple air holes can be formed between fibers as the thermal heating layer to achieve the function of preventing the heat from being divergent, comfortable, soft, and warm -lasting. After the fabric research and development proposal passed, the designer referred to the consumer purchase intention and sales information of the headquarters to design the clothing style, and then discussed with the board of the board to solve the details of the clothing version, size and other details. Design and version.

After the design scheme is passed, the next production plan is formulated, including the number of products, color, and delivery period. Uniqlo does not show customers the latest clothing style, avoiding the seasonal fashion clothing that other companies would rather be sold and sold, and highlights the basic clothing produced in all brands, and branded it as the main product.

In addition, its product line expands from women's clothing, men's, children's clothing to men's and women's and children's underwear, and also adds underwear products that are not affected by fashion factors and can be worn. The reason why Uniqlo's customer group can continue to grow is precisely because the products it designed is not affected by the trend.

2. Product production stage

Large -scale production is different from the small and small variety strategies of ZARA. Uniqlo adopts the strategic method of "a single product of a single commodity" to reduce costs. In other words, when Uniqlo places orders in the factory, it will reduce the types of commodity production, and for a piece of orders of tens of thousands to hundreds of thousands of pieces at a time. After receiving the order, the production department will put the order to the cooperative production plant, and urge the production progress of the factory to test the quality of the product.

After the production of the manufacturing plant completes the order, the goods will be sent to the designated warehouse of Uniqlo, and the warehouse will be uniformly allocated and distributed to each store. Considering the cost of production, Uniqlo basically adopts the form of outsourcing in product production, and commissioned production to foundries in China and Southeast Asian countries for production.

In 2019, the half -year financial report shows that as of May 14, 2019, Fast Metro Groups have 242 foundries in 11 countries including China, Indonesia, and Myanmar. Essence In order to reduce production costs and also reduce dependence on China's manufacturing industry, Uniqlo is planning to transfer production bases from China to Southeast Asian countries in the next step. The implementation of the "craftsmanship plan", Uniqlo attaches great importance to product quality. The company has carried out the "craftsmanship plan", that is, the technical talents with clothing production of more than 30 years of work experience from the Japanese domestic network, allowing them to teach the workers in foreign foundries to teach textiles and textiles. A series of operating technologies such as weaving, tie -dyeing, processing, and shipment.

This "textile craftsman team" was gradually developed from a small organization of the initial 13 people, and then slowly developed to the scale of 40 people. It is precisely because of these experienced professionals to guide the guidance that Uniqlo's high -quality clothing can be guaranteed. A large number of products in a single product have made the product production stage achieve low prices. The craftsman plans to ensure the high quality of the product and enable the product to achieve "cheap and good quality."

3. Product sales stage

After receiving the clothing from the production plant, the warehouse will be sent to each store according to the order of each store. After the product arrives at the store, the manager is displayed and managed the sales progress in the store according to the color and size according to the weekly sales plan. The headquarters managed the inventory department will issue the next supplementary or return instructions according to the sales and deposit on the store.

When the sales performance of the store does not meet the goal of the sales plan, the headquarters will instruct the price reduction, adopt two methods of "limited time excellence" and "super -value selection" to attract consumers to buy and achieve sales. In response to the imbalance of inventory when each store is discounted, the director and store manager responsible for the regional stores will be delivered to the stores that are sold slowly to the corresponding product sales performance after communicating. The inventory of discount products will be improved to increase sales.

Those products that have less inventory and can be sold by each store themselves can be reduced again after deciding by the manager, and they are sold on mobile shelves around the store to attract customers. Uniqlo takes customer satisfaction as the primary goal. It is believed that by collecting consumer information, especially to improve the consumption satisfaction of customers in stores, it is the most important. Therefore, it has always advocated providing customers with a good shopping experience.

Fourth, comparative analysis of ZARA and Uniqlo SPA model

Through the introduction of the SPA supply chain model of ZARA and Uniqlo, it can be found that ZARA's product is strong, and its production and logistics turnover speed is stronger, and the profit margin of product sales is higher. Uniqlo is mainly based on basic clothing, versatile fashion, and has unique advantages in the development and quality of product fabrics.

During the product design stage, both enterprises are designed by establishing direct -operated stores from the sales data of direct -operated stores and the fashion information collection information of the show. Both of them have invested a lot in the early R & D and design links of the products.

The difference is that ZARA is re -designed through the clothing of the fashion show. Its main trendy women's clothing, the audience is smaller and easy to be affected by the market trend, while Uniqlo is mainly based on the basic clothing, which is less affected by the fashion trend. The types of goods are richer and the audience has a wider range of products. Because of its scientific and technological research and development of fabrics, the quality of goods is better than other companies in the same industry.

During the product production stage, ZARA is a small number of products. According to the sales situation, it is added in the season. The goods are processed and manufactured in Spain's own factories, and transported to various stores through air transportation. This can ensure that the goods can be new in time. Uniqlo is a production plan for the initial year of the first year. Its production strategy is a large number of single products production. It is produced in foundries in China and Southeast Asia.

By comparing the comparison, the model of ZARA multi -variety and a small amount of production has reduced the inventory pressure to ensure the profit margin of the product. The production of its own factory saves costs and accelerates the capital flow. ; High -speed logistics systems ensure the rapid newness of goods and win market opportunities.

During the product sales phase, ZARA has timely adopted the product with incompletely removed numbers and launched a new product twice a week to attract customers. The price reduction rate of the product is low. And Uniqlo adopts to avoid the products that avoid the shortage of the product and make up at any time. It is used to digest inventory by adopting a limited -time excellent and price reduction sales strategy and online and offline sales channels. In contrast, ZARA's production model has made its inventory less backlog, the price reduction rate is low during the later sales process, and the turnover of turnover profit is more.

At present, there are some shortcomings in the SPA mode:

(1) High construction cost in the early stage

The SPA model requires a lot of capital investment during design, production and sales. Product research and development in the design stage, the construction of its own factories and logistics systems in the production phase, and the construction of direct stores during the sales phase must consume a lot of funds and labor costs.

(2) Great inventory risk

During the production stage of the SPA model, enterprises will produce large -scale production in advance in accordance with the product design plan. Once a mistake of market judgment will cause a large amount of product backlogs.Sales situations formulate price reduction promotional measures in a timely manner, and combined with online sales to digest inventory.5. What time is inspiration

Increase product research and development efforts, participate in the development and design of early fabrics to improve their own brands, and the style of clothing style and display brand style improves production and logistics, improve store self -service services to broaden online sales channels, improve online and offline services synchronization

Public account: Twenty -three summer (ID: yingbaodexiaowo)

This article is published by@本 本 本 本 is a product manager. It is prohibited from reprinting without permission.

The question map is from UNSPLASH, based on the CC0 protocol.

- END -

Science of Epidemic Prevention | What is the difference between home health monitoring and home isolation medicine observation?Take you understand

Source: Healthy China

Yajiang County Meteorological Observatory lifted the rain and blue warning [IV level/general]

Yajiang County Meteorological Bureau June 08, 2022, at 16:49 on June 07, 2022, at 17:40 on June 07, 2022.