Cross -time and space collaboration weapon -infrastructure BIM platform based on life cycle management

Author:Bridge magazine Time:2022.06.21

The security and stability of infrastructure have always been an important factor affecting the development of the country's economic and social development. In the past few decades, due to the inefficiency of the traditional infrastructure management system and the waste of resources, people have increased their demand for technological improvement, and hopes to manage aging infrastructure more economically and effectively. The construction information model (BIM) technology has been recognized as the preferred tool for management of construction engineering, project owners and operators. At present, there are more and more research on infrastructure areas such as roads, bridges, tunnels, and the construction industry.

New attempts in the general data environment

BIM has the advantages of infrastructure from planning to construction and maintenance, and the full life cycle management advantages. The introduction of BIM during the planning phase can systematically strengthen the collaboration between project management and stakeholders. At the same time, BIM also helps collaboration at the design stage, improve design quality and reduce errors. In the construction stage, BIM can improve production efficiency and workflow by reducing the waste of time and resources. In addition, the infrastructure BIM data stored in the planning and design phase can be used for later maintenance. Integration through BIM and advanced technology, such as robots and UAV systems with digital cameras, 3D laser scanning and light detection and ranging (LIDAR), 3D model construction algorithms and artificial intelligence algorithms can effectively maintain infrastructure Essence

By 2027, the global BIM market size will expand to $ 15.06 billion. The United States, Canada, Germany, Britain, China, Japan, India, South Korea, Singapore and many other countries have adopted and developed related BIM tools. In South Korea, the Ministry of Land and Transport (Molit) announced in December 2020 that BIM was introduced in infrastructure projects in the construction industry. "Basic Guide to the Construction Industry" and "BIM Activation Road Map of 2030" pointed out that through the information of the planning, design, construction, and maintenance phase of the construction industry through sharing the construction industry in the construction industry, it is a good way to manage the life cycle of infrastructure Prepare to maximize productivity. In addition, in the "Bid Guide of the Construction Industry BIM (2020 Edition)", it also requires BIM's procedures for architecture, the main standards and general data environment defined by BIM. Therefore, it is recommended to use international standard formats, such as IFC formats and scalable markings XML in industrial basic categories to manage infrastructure in the universal data environment. Because infrastructure management projects involve different interest -related stakeholders, different software programs, such as Autodesk Bim 360, Trimble Connect, Bentley, etc., are usually difficult to achieve data exchange. Therefore, the latest technologies of infrastructure management have been systematically analyzed in this article. A BIM -based life cycle management method is proposed. By using infrastructure BIM platforms, the stakeholders in the universal data environment can cooperate in construction management. Through the regular inspection database based on infrastructure BIM platforms, the systematic management of time analysis, damage growth forecast, maintenance and demolition decision -making, etc., to achieve the full life cycle management of infrastructure.

Application of multiple cutting -edge technologies

Third -stage infrastructure management

Although the infrastructure will go through many stages in its life cycle, it can be mainly divided into three stages for analysis: planning, design, construction, and management. In the planning stage, BIM can help decision makers effectively and quickly determine the best solutions in many scenarios. BIM has been applied from large projects, making communication simple, and at the same time, it has strengthened collaboration among different stakeholders. BIM is also applicable to reducing design errors in the design stage, improving quality, inspection quality and conflict. HASSLER and BORRMANN proposed 14 quality parameters to establish standardized design quality verification methods. Park and others proposed an extended IFC model, but they were still unable to complete the steel box beam bridge. They developed an IFC -based steel bridge information model during the design stage. Borrmann and others have developed a multi -scale BIM shield tunnel model based on IFC, using multi -scale models in CityGML to convert. NATH and others have proposed BIM -based prefabricated workshop drawings to enhance workflow. Girardet and Boton have developed a parameter file to design and generate any type of bridge to solve the difficulty of application in the bridge engineering in the BIM mode. A complete BIM model is of great significance in the planning and design stage, which can not only reduce construction errors, lacks, and conflicts, but also improve construction quality and processes during the construction stage. Shin et al. Using 7 construction projects to verify the advantages of BIM at the railway construction site. Lee and others have developed a bridge BIM model to combine the design of the prefabricated box beam bridge. LIU and others have developed 4D Geobim to combine BIM with geographic information system (GIS) to ensure construction efficiency and safety. Koch et al. Put up the tunnel information modeling framework for the construction of a security tunnel. Of course, the time, cost, and resource management of the construction phase are also important. Mawlana and others proposed 4D BIM to build and rebuild highways in order to prevent the probability of potential space -time conflict. DING and others have developed a multi -dimensional modeling technology to integrate the work decomposition structure (WBS) and other construction structures such as rail transit construction. After construction, infrastructure needs to be regularly monitored to ensure its functionality and security. In the United States, the National Bridge Inspection Standard (BNIS) requires highway bridges to check at least every two years. In South Korea, infrastructure has been managed regularly in accordance with the "Special Law on Safety Control and Maintenance" since 1995. The structural health monitoring of infrastructure is the main content of life cycle management. Valdependas et al. He developed BIM for port maintenance. Lee and others have developed the BIM-3D GIS system framework to effectively maintain the comprehensive pipe gallery. Sharafat and others have developed the BIM-GIS framework for the underground public business management system. Boddupalli et al. Put up a SHM-BIM digital platform for automated health monitoring of infrastructure. Kaewunruen and others proposed 6D BIM for the time plan management, cost estimation and carbon footprint analysis of the bridge's life cycle. The latest technology for three -dimensional model construction

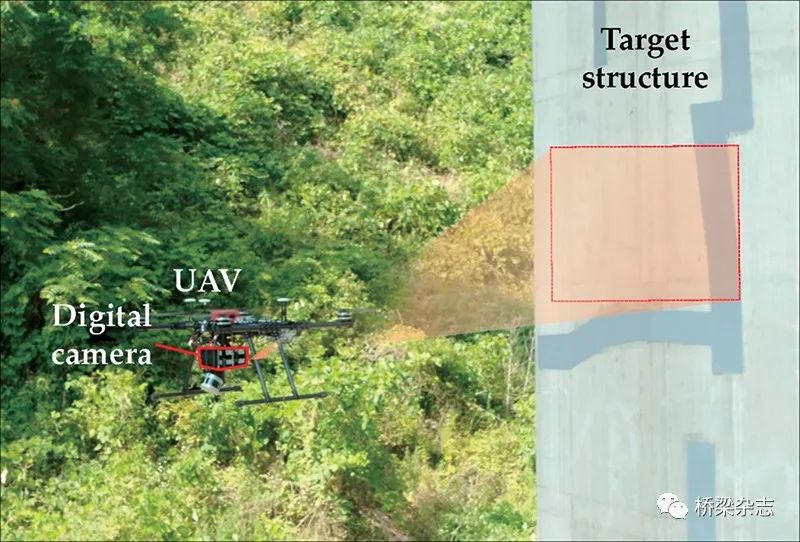

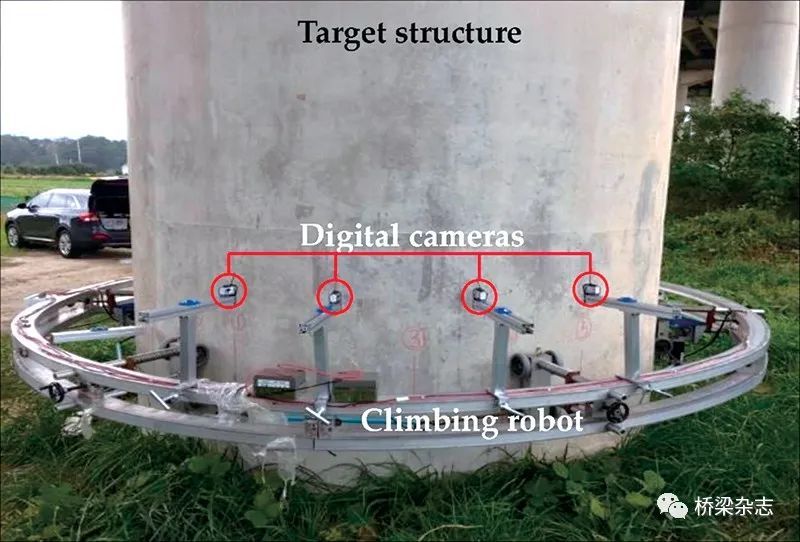

It is difficult and dangerous to check large -scale infrastructure, especially in areas where inspectors are difficult to enter. Therefore, there are many experiments to apply sensors on robots and drones, such as digital cameras, laser radar, etc. Kim and others have developed a drone system for the monitoring of concrete bridges. Jiang and ZHANG developed a kind of crawler on the wall to detect the surface cracks of the concrete bridge. Ribeiro and others proposed a structural health monitoring system that uses drones for high -level communication towers. JANG et al. A number of camera climbing robot systems for the assessment of concrete bridge crack assessment. The data collected from the sensor on the robot is used to create a 3D model. Lidar is widely used in the establishment of a built -in infrastructure 3D model in the digital field. The photography measurement algorithm can also use digital images to create a three -dimensional model, and the BIM model can also be generated using three -dimensional cloud data.

Evaluation of automatic injury of infrastructure based on deep learning

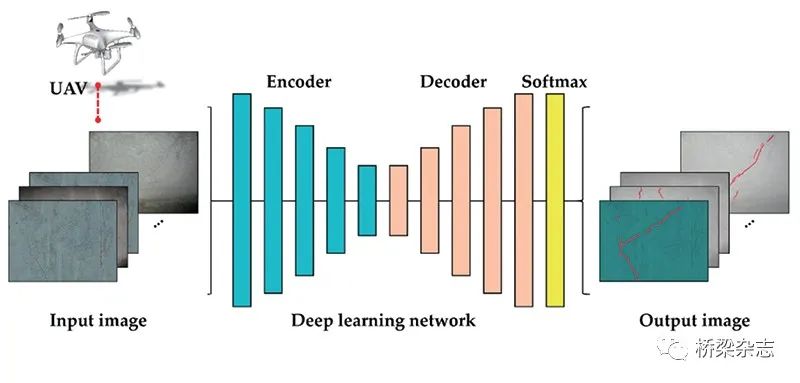

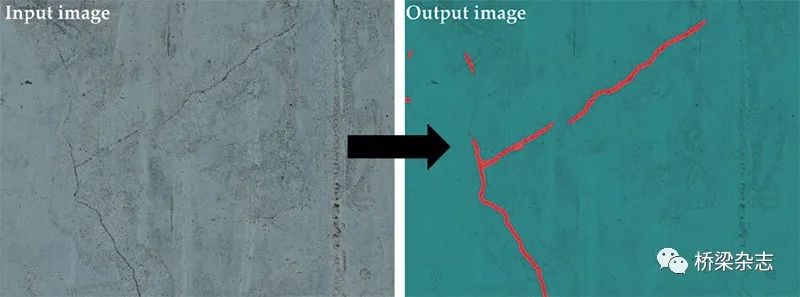

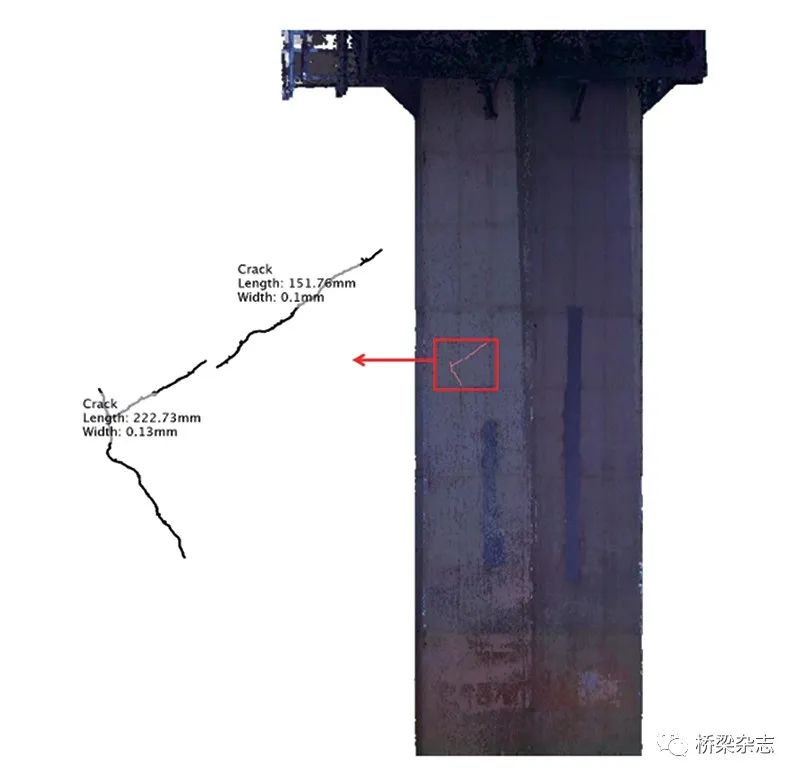

In order to discover the damage of infrastructure as soon as possible, the visual inspection technology has been widely accepted in the past few decades. However, visual inspection is unsafe, time -consuming and unreliable. In order to overcome these problems, the image processing method is proposed as a replacement method for visual detection, but the harsh infrastructure environment interferes with the application of the image processing module. Recently, people have proposed deep learning damage assessment technology, which can automatically make decisions based on reliable damage evaluation results. Damage classification technology based on convolutional neural networks (CNN) has been proposed. CHA and others proposed CNN's crack detection of sliding window technology. Kim and Cho used Alexnet's migration learning technology to develop a "vulnerability detection network". Jang et al. Put up a concrete crack detection network using a hybrid image scanning system. Dorafshan et al. Verifically verified the concrete crack detection method based on deep learning, which has better performance than image processing methods. Hoang et al. Also confirmed that the effect of road crack detection based on deep learning is better than the image processing method. In addition, the regional convolutional neural network (R-CNN) has been used for automatic positioning damage. CHA and others have developed a faster R-CNN to classify and locate multiple damage, such as cracks, corrosion and bridges/buildings. ZHANG et al. He developed a YOLO -based algorithm to classify and locate a variety of damage to the bridge. The semantic segmentation network has been widely used in pixel -level damage areas. FENG et al. Followed the crack CDDS network of the dam structure segment based on semantic segmentation networks. LI and others proposed a multi -damage segmentation network that combines Naïve Bayes data fusion methods with FCN. CHOI and CHA propose SDDNET for real -time crack detection. Deep learning technology is usually used for automatic damage detection software for robot systems. Kang and CHA developed a CNN for crack detection for drones (UAV) system. Kim et al. Use R-CNN to develop bridge crack positioning for drone systems. Jiang and ZHANG developed a real -time crack segmentation network for climbing robots. Jang et al. He developed a crack division network for climbing robots. Efficiently and accurately simulate the whole life cycle of infrastructure

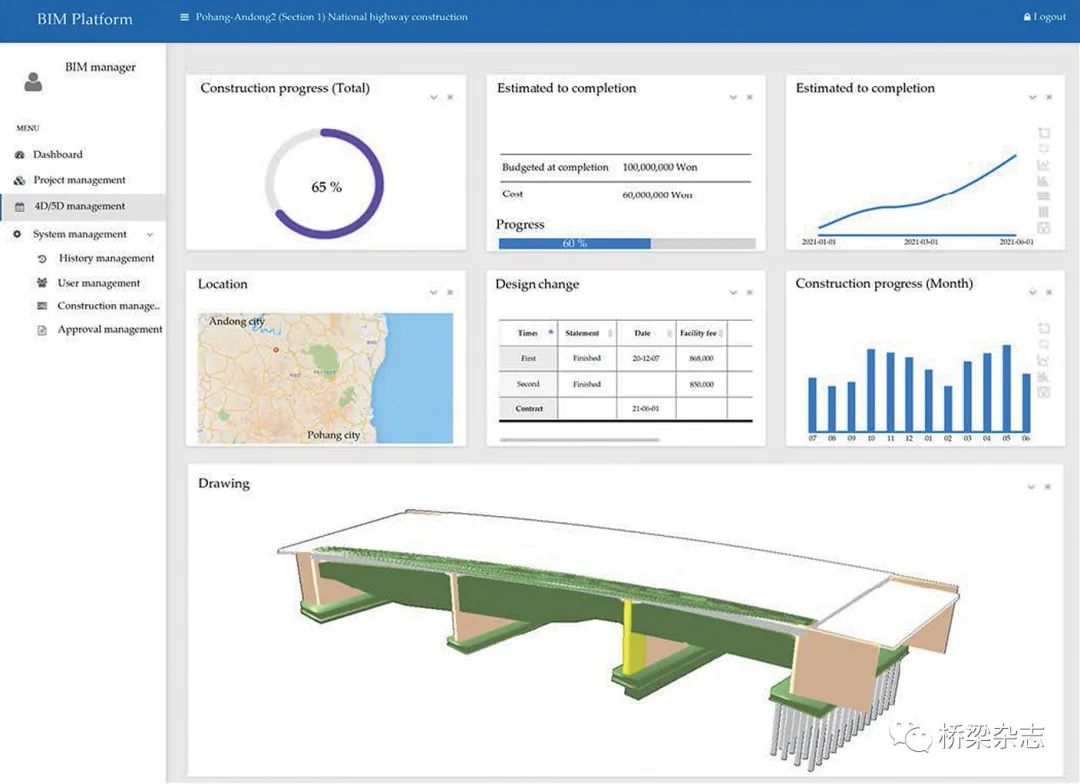

On the basis of many data algorithms, the BIM and the most advanced technology are combined to propose infrastructure BIM platforms. Infrastructure BIM platforms are mainly composed of 5 parts: planning and BIM model design; construction management and monitoring based on 4D/5D BIM; scanning to BIM, use data collected from the built -up infrastructure; Automatic injury assessment and charts; annual grades of infrastructure for life cycle management. For the construction of a general data environment, the platform is based on the web architecture, covering the full life cycle from planning to demolition from infrastructure. First of all, the 4D/5D BIM model is established based on the 2D design model, work/organization/cost decomposition structure; then systems are systematically used using 4D/5D BIM models. 4D/5D BIM models are used as international standard formats (IFC and XML) and interests Related parties shared. After completion, use sensors of embedded robots to collect data and scan the establishment of texture mapping BIM models. Use the trained deep learning network to automatically detect the damage in the data collected. Establish a damage mapping BIM model by mapping the detected damage to the BIM model. The infrastructure is regularly classified and managed by the laws of various countries. Therefore, the BIM model is updated regularly, and the outdated BIM model becomes a reference model, and then explains the special part of the infrastructure BIM platform.

Access at anytime, anywhere

An infrastructure BIM platform should be developed into a network -based platform, which is compatible with the habits of many different stakeholders, such as customers, BIM managers, construction managers, and safety managers. In addition, a network platform that does not require other software aids can meet users to visit anytime and anywhere. Using a network platform in a general data environment can significantly reduce information, cost loss and errors during communication. When infrastructure projects begin to build, all participants in the project register on network -based infrastructure BIM platforms. Every step and information of the project will be updated and shared with you. IFC and XML files are uploaded after the plan is determined, and the IFC checker and the viewer automatically check the design of the design mode of the design. If the uploaded file is accepted, the construction progress, location, date, cost, etc. will be displayed on the dashboard. The progress and cost of infrastructure construction are managed based on the working decomposition structure and cost decomposition structure, and have been embedded in the computing module of the infrastructure BIM platform. Therefore, when uploading IFC and XML files, the number, progress and cost will be automatically calculated by the calculation module.

Use the most advanced technical management infrastructure

After the infrastructure construction is completed, the damage already exists or occurs immediately. Therefore, the infrastructure must be checked, and then you can refer to the built BIM model. Various robots are widely used. For example, the climbing robot scanning bridge table with a built -in digital camera is used to update the collected data to the BIM model. Similarly, the drone with only one digital camera can also scan the entire bridge surface, combining the collected data with photography measurement algorithm to create a 3D model. Detect damage in the collected data through deep learning networks, and train this network to detect multiple types of damage, such as cracking, peeling, rust, and reinforced reinforcement exposure. Then use the segmentation area in the output image to calculate the length and width of the damage using the image processing algorithm. Save the results of quantitative analysis and map it to the BIM model. The future of digital twin models

Establishing a digital twin model is the goal of infrastructure life cycle management. However, digital twin models are still applicable to data sharing and visualization. Use the historical time data stored by infrastructure BIM platforms to establish an artificial intelligence -based injury growth forecast algorithm. Then, through the most advanced technology, the life cycle management of infrastructure can be realized in the digital field. In the general data environment, the BIM -based collaboration with the stakeholders can effectively realize the life cycle management of infrastructure. Related stakeholders can use Web -based BIM platforms to access and exchange the necessary information in real time, thereby improving the efficiency of infrastructure life cycle management. Recently, advanced automation technology has been widely used in the field of infrastructure management. Especially through drones, climbing robots, etc., the automation of data collection is realized. In addition, machine learning or deep learning networks make the corresponding data processing fully automated. However, using the web -based BIM platform, the life cycle management of the system is still difficult. Although there are a lot of tests in the initial stage of the data management of infrastructure modeling, real -time or periodic data updates are still technically challenging. In order to achieve technical requirements, the data collection system and timing data processing system that is updated in real time is needed. As a promising follow -up study, the author's team is currently developing a digital infrastructure twin modeling and automatic update technology, integrating with the current BIM platform.

This article published/ "BIM Vision" magazine 2022 The 21st author of the 22nd issue/ Keunyoung Jang, Jong-WOO KIM (Korean) and other authors/ Korean Sejong University Construction Engineering Department, UDNS Co., Ltd., Korean civil engineering and construction technology Research institute

- END -

"Former Guerrilla Member" was elected President of Columbia

Xinhua News Agency, Bogo University, June 20th. The preliminary counting results a...

A major immigration tragedy in the United States: at least 46 people died in the truck to rush to the scene

Live map (WOAI TV)Overseas Network, June 28th. On the 27th local time, a major imm...