The "Bridge Make" appeared!Building a bridge can be so simple

Author:China Railway Time:2022.07.07

Highway bridge construction you have ever seen

Is it like this?

Footwork Lin stands

Crane

Low construction efficiency

Long construction cycle

Bridge construction 2.0 era

The traditional bridge machine is used

Can only be set up beams

now

China Railway is developed

A "Bridge Creation Artifact"

The world's first pile beam integrated intelligent bridge machine "Communist Number"

Promote the construction of bridge into the 3.0 era

Today, the little blacksmith will take you to know it together!

Panorama of homework

"Communist Number"

92 meters long, 13 meters wide, 575 tons from weight

Effective span is 48 meters

Adopt Beidou positioning system pile

Realize the hole, pile, beam

Formation of "air" operation in the assembly pier

It is especially suitable for shallow water lakes and swamp wetlands

Environmental protection zone, urban prosperous area, etc.

Areas that cannot be exhibited in traditional construction methods

Eight national invention patents have been applied for

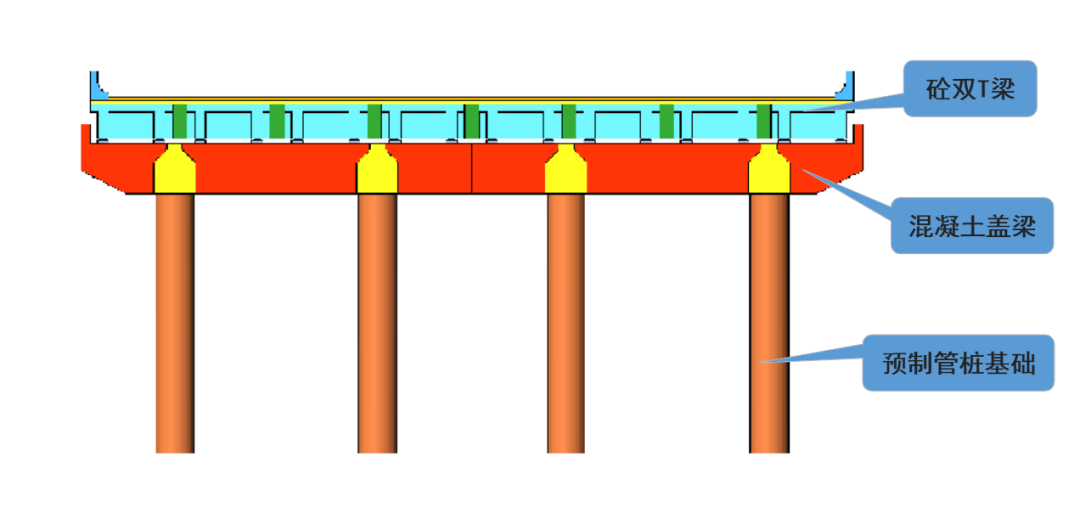

Below is the composition of prefabricated highway bridges

The upper, middle and lower structures are respectively

Premium premature concrete dual T beam

Pretending reinforced concrete cover beam

Prefabricated pipe pile foundation

So how does the "co -worker" be above

What about highway components?

To facilitate everyone to understand intuitively

Little blacksmith brought decomposition action

Piling device horizontal shift

Diamond pipement operation

Two 10 -ton sky car lift the hanging pipe pile

Piling device for pile pile pile operation

60 tons of sky car hanging up the cover beam for installation

The whole machine is over -the -hole operation

T beam installation

to here

As soon as a cross -road bridge is completed

Are you super liked?

In recent years, the national environmental protection requirements are high, the construction period is tight, and the construction environment is complex and changing, which has led to the demand for prefabricated buildings. China Railway Science and Technology workers boldly innovated, extended the advantages of moving to the pavement to the field of prefabricated building equipment, and developed a number of construction equipment for prefabricated buildings. In addition to the "Communist Number", China Railway Science and Technology also developed the first domestic building component assembly robot and the first domestic installation of the assembly process and equipment of the full -fitting subway station, which provided technical support for the development of prefabricated buildings.

The first domestic building component assembly robot "Chisha"

In June 2021, China Railway Science and Technology Research and developed the first domestic building component assembly robot "Chisha", with a total length of 80 meters and a weight of 120 tons. The effective span reached 69 meters. The "legs" of independent movements can independently retract each leg and walk horizontally and vertically to meet strict construction requirements such as passing unpopular steps, tower cranes, and paddling hollow. Construction of vehicle sections.

In addition to giving full play to the advantages of the beam machine, the "Chisha" robot also sets up a number of keen "eyes". It only needs 1 driver operation and 1 person command to achieve functional humanization, automation and intelligence. The upgrade of the assembly operation from "line" to "surface" components was guaranteed. Compared with the traditional construction method, not only greatly reduces the labor intensity of personnel, saves a lot of manpower, has increased its efficacy by more than 1.5 times, but also greatly reduces the generation of construction noise and dust.

The first domestic installation and matching subway station assembly process and equipment

Recently, the first domestic full -duty subway station assembly process and equipment jointly developed by China Railway Science and Technology and other units were successfully applied to Pingxi Station on the fourth phase of the Shenzhen Metro Line 3, which brought new changes to the construction technology of the subway station.

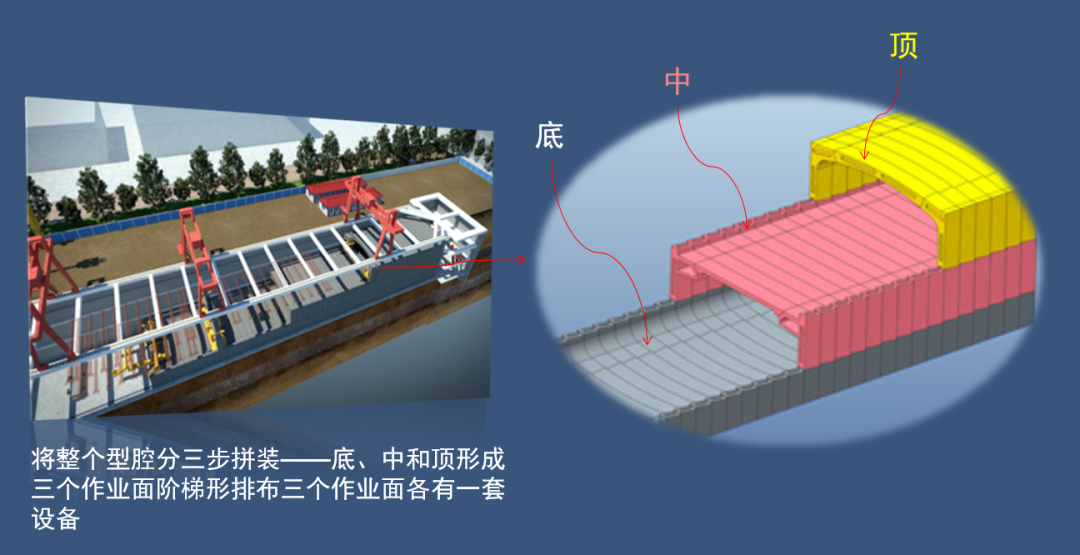

Equipment subway station composition

The construction equipment of this set of stations created the first three operating surface staircase distribution and the three assembly machine synchronous construction models. The three assembly machines stitched the modular prefabricated parts in accordance with the top, middle, and bottom layers. The weight of a single prefabricated piece is light, which is convenient for flexible transportation in the city. During the installation process, the device can rely on the GPS high -precision positioning system to achieve the precise, flexible, efficient, and safe of the prefabricated component assembly assembly and adjustment process.

Underground assembly machine construction

Construction of middle -level assembly machine

Construction of the top layer assembly machine

Compared with the traditional paddling construction method, this construction method has decreased by 80 %, and the construction efficiency has increased by more than 2 times. Trends, with broad application prospects.

How about it?

"Building blocks" in these architectural circles

Is it amazing to you? Intersection

In the future, China China Railway

It will continue to lock the industry's frontier technology

Create more and better tooling equipment

To promote the high -quality development of the construction industry

Contribute China Small Wisdom and Power

Editor -in -chief 丨 Li Yuan, Shen Su

Editor -in -chief 丨 Shao Jun, Xu Huimin, Pan Wanqi (Science and Technology)

Content source 丨 China Railway Industry

China China Railway Finance Media Center

- END -

How strong is the Fujian ship?Even American experts are jealous ...

my country's third aircraft carrierFujian Shipcoming!June 17thmy country's third a...

"Do you understand Chinese?", "I don’t understand" ... Pakistan frigates and soldiers are in interest in Chinese with Chinese

Do you understand Chinese? I don't understand. During the co-starring stage of Oce...