Sad!He is gone, only 48 years old ...

Author:Hubei Daily Time:2022.09.25

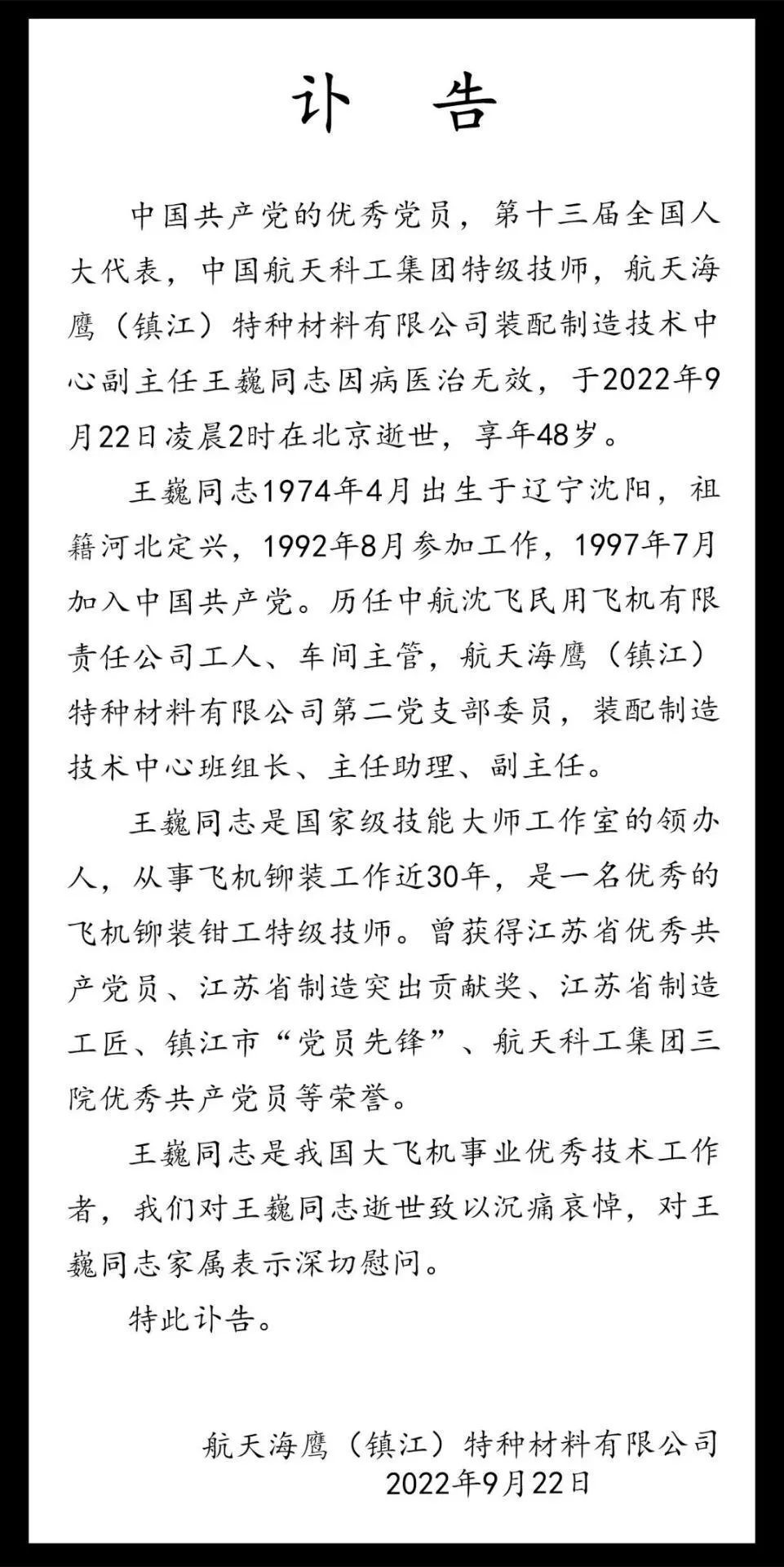

On September 22, the Aerospace Sea Eagle (Zhenjiang) Special Materials Co., Ltd. issued a notice that Wang Wei, a special technician of China Aerospace Science and Industry Group, died in the early morning of the day at the age of 48.

Wang Wei has won a number of honors. He is a leader in Jiangsu Province manufacturing craftsman and a national skilled master studio. During his lifetime, he exceeded many difficulties in the field of aircraft assembly and made a great contribution to the delivery of the first large domestic aircraft.

Wang Wei's workmates before lifetime

Overcome multiple technical difficulties

Started the front line for two consecutive months

In the second half of 2015, Wang Wei received the assembly mission behind the fuselage after the C919 passenger plane. He said, "The complete independent C919 large aircraft is a new thing. Many technical issues during the assembly process are also the first time I touched it arrive."

There are hundreds of parts and tens of thousands of standard parts in the back of the fuselage of the C919 passenger aircraft. It is necessary to complete 15 -hole test projects, involving more than 1,800 composite material test films, and the number of holes reached more than 20,000. In order to ensure the smooth delivery of the back of the fuselage after the first machine, under the circumstances of heavy tasks, no foreign aids, and the difficulty coefficient, Wang Wei gave up holiday rest. , Solve various technical problems. In the end, the development and assembly work of the post -rear stage after the C919 was successfully completed, and it contributed a huge contribution to the delivery of the first large domestic aircraft.

Wang Wei studied hard before his lifetime, and he was improving. The technical difficulties of the aircraft assembly riveted were overcome by him one by one:

Successfully solved the technical difficulties of composite materials and holes;

By improving technology and optimizing the inspection process, the component assembly cycle is shortened by more than 30%, and the research results will be promoted and applied in the assembly of other composite material components in C919 to be highly recognized by the Chinese COMAC experts;

Participated in the research and development of digital manufacturing technology based on digital testing, which reduced the manufacturing cost by 30%-40%, the product development cycle was shortened by 40%-60%, and the technology was applied to the assembly of the rear fuselage behind the first machine;

The hole -making experiments of the composite material parts were performed to meet the requirements of the process compliance with composite composite material -based structure -made holes in composite materials. supplier.

Since becoming a representative of the National People's Congress, he has proposed a number of suggestions such as "improving the introduction of skill talents and retaining talents", "improving the protection of grassroots courts", "strengthening the supervision of short video APPs" and "proposals to abolish relatives".

farewell!

The Hubei Daily client, paying attention to the major events of Hubei and the world, not only pushing the authoritative policies for users, fresh hot information, and practical convenience information, but also launched a series of features such as reading newspapers, newspapers, learning, online interactives.

- END -

Long March 7 changed the shipping rocket to achieve a new breakthrough

The launch preparation time further shortens the Long March VII to the Rocket Rock...

Back to the hometown to board the car, the gift package of "Iron Fist" is really warm

Text 丨 Zhang Yongqiang, Li SongFigure 丨 Zeng Shunhua, 图 华 顺Another year of re...