I did not expect that icing had a great impact on the aircraft flight!

Author:Institute of Physics of the Ch Time:2022.08.15

""

The scenery of the northern country is frozen thousands of miles, and the snow fluttering. The world of the ice and snow in Chairman Mao's verses is so vast and magnificent, but you have understood that the "silver -wrapped" under the frozen is a nightmare of flying lingering.

01

Flying "Ice"

Have you ever encountered such a situation: In winter, when you are in a hurry to sit on the flight to fly to your destination, you are told that the flight is delayed. Flying is mainly "safe", and icing will bring major flight safety hazards. The accident caused by icing accounts for about 12%of the total accident, of which 60%occur during aircraft cruise and entering the field. On November 21, 2004, a CRJ200 was frozen shortly after taking off, causing a crash, causing 53 people on the plane and 2 people on the ground. On June 3, 2006, a transport-8 aircraft in Wuhu, Anhui was due to Frozen crashes caused 5 members of the aircraft and 35 top radar experts to sacrifice; in January 2018, a 8th aircraft transported by a aircraft in Guizhou died due to flat -tail ice.

Studies on aircraft icy can be traced back to the beginning of the last century. In the 1930s, people invented the initial aircraft ice removal device. In 1948, Preston and Blackman completed the first aircraft icing test. The results showed that the ice -cutting resistance increased the flight resistance by 81%, and the pilot felt that the entire aircraft was out of control. With the requirements of new aircraft design and new performance, aircraft freezing and sailing will only become stricter. In the Appendix C of the Appendix C Regulations of the Federal Aerospace Administration (FAA), there are strict regulations on transport aircraft and drones. The assessment of airplane's aerodynamic characteristics after the natural freezing was once the last "blockbuster" in the ARJ21 aircraft aircraft availability. The C919 large aircraft faced with freezing and availability problems faced after the first flight, which also made research related to icing a research hotspot.

02

The strange ice shape and the mechanism behind it

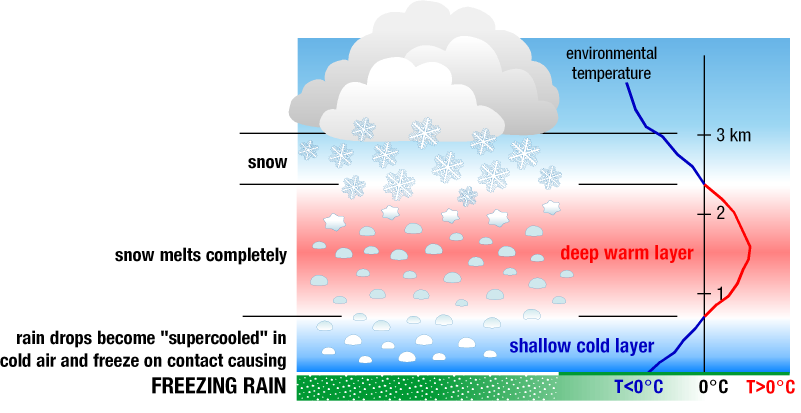

We know that the water will freeze when the temperature is lower than the freezing point (0 ° C). However, there is such a group of uneasy water droplets in the air. Because of the lack of consolidated tuberculosis, they can still keep liquid when the temperature reaches -20 ° C. This small water droplet is also called cold water droplets, as shown in Figure 1. In the high altitude, when ice crystals or snow falls, when you encounter warm air melting, cold water droplets will be formed. This situation is more likely to happen when the cold and cold air ball meets and forms a temperature layer.

Why do you say that cold water droplets are restless? Because this group of over -cold water droplets is very unstable, and the energy of the object with low energy will form an ice instantly. If the energy is higher, the energy will overflow along the object until the energy is exhausted and frozen. The impact of the "base" frozen, and some escaped to the surrounding frozen to form a "trend of Liaoyuan", which eventually led to a strange ice shape. According to the shape of the ice and its impact on the aerodynamic characteristics, the aircraft can be divided into frost ice, ice, and ridge ice.

Figure 1 The cloud droplet and the cloud that bred it

(Picture source: NSSL)

"Short, flat, fast," Frost Ice: Frost Ice is usually formed in a cold atmospheric environment. The corresponding freezing process is relatively simple: when the cold water droplets hit the lift surface, it instantly freezes into ice, and there is almost no overflow. In the short time, the frost ice is attached to the flat layer of the front edge of the wing type, which can still maintain the shape of the streamlined body, as shown in Figure 2.

Figure 2 Swatch diagram of frost ice ice and its flow field

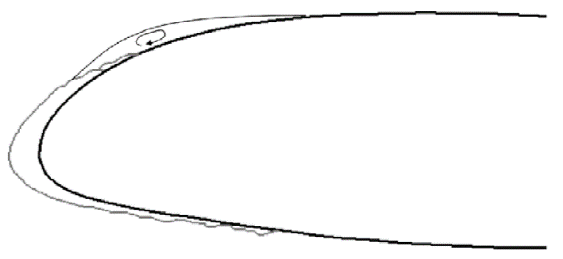

Stubborn and dangerous Akimoto: Akimotive is a transparent ice, and it is also a kind of dangerous ice. The atmospheric temperature of the environment is relatively high, the size of the cold water droplets is large, and the liquid water content is high. Flying speed. The shape of the ice ice is shown in Figure 3. The density of Mingbing is usually large, and the Bingbing on the wings is very strong and it is not easy to be removed.

Figure 3 Ming Ice Ice shape and their geometric characteristics

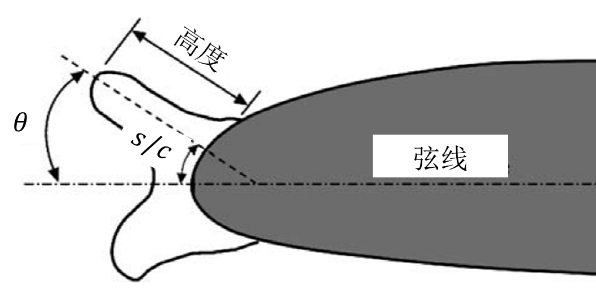

"Invincible" ridge ice: Most of the spine ice accumulates under the conditions of over -cold water droplets (SLD). Too cold water droplets refer to too cold water droplets with an average droplet diameter (MVD) greater than 50. Usually after the spine ice accumulation is in the front edge ice removal device, when the front edge of the wing is opened, %Evolly the water or ice melted in the impact, and the water will flow backwards along the surface of the wing, and reinserate the accumulation of ice in the non -protected area, as shown in Figure 4. The harm of the ice type to the pneumatic characteristics is the largest of several ice types.

Figure 4 Spinal ice -shaped

03

How to predict the airplane freezing?

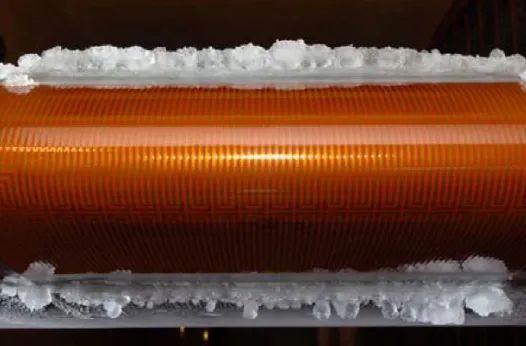

Ice wind cave test simulation: Frozen aircraft is a complex process of solid, liquid, gas flowing, heat exchanging, and phase transformation coupling. It is the most reliable method to simulate the ice -winded ice ice. The icing tunnel (IRT) wind tunnel (IRT) wind tunnel (IRT) and Italy's icing wind tunnel (IWT) of the United States Aerospace Aviation Agency (IWT) is a well -known ice -winded cave in the world. The FL-16 of the 3m and 2-meter icing wind hole of the China Air Power Research and Development Center has also played an important role in the freezing test of multiple models in my country.

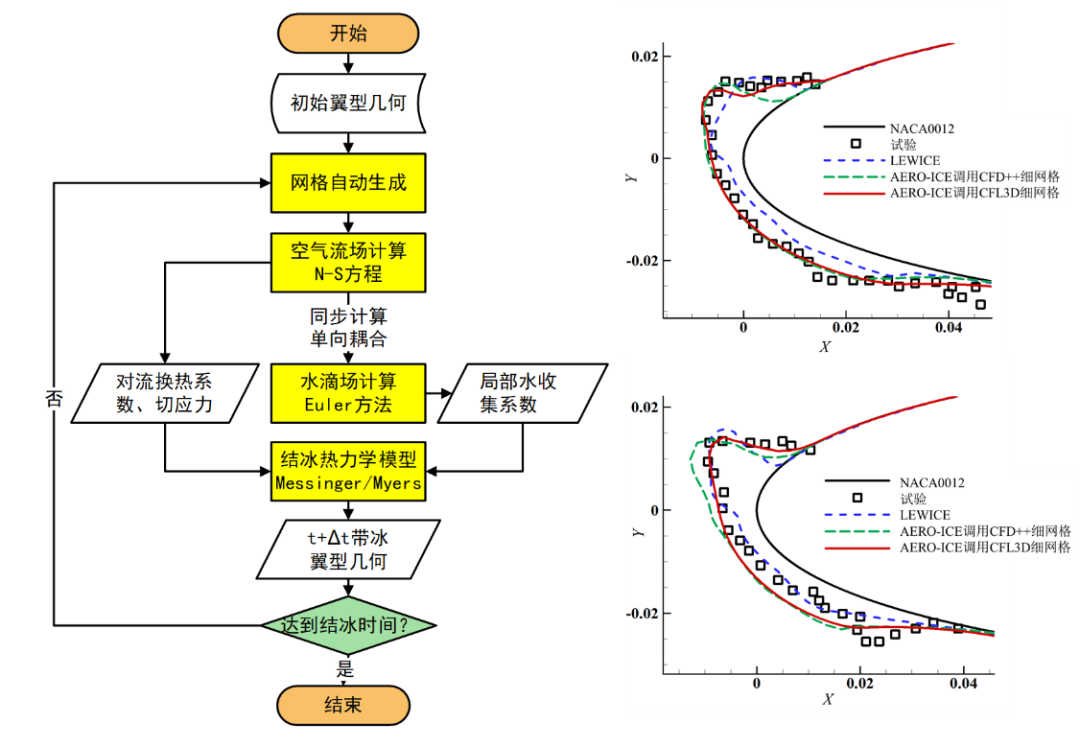

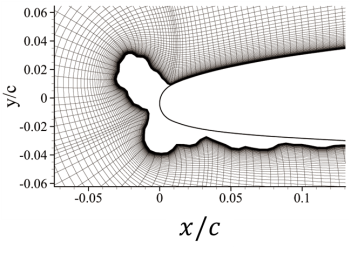

Software numerical simulation: Numerical simulation has the advantage of low cost and short cycle compared to wind tunnel tests. From the 1950s and 1960s to the present, a large number of freezing value calculation research has been carried out in Europe and the United States, and a number of mature software has been formed, including: Lewice and Lewice3D software developed by NASA in the United States; Fensape-developed by Canadian NTI companies ICE software has been acquired by ANSYS; ICing Code, France's ONERA; Plimice in Italy; Trajiced developed by DRA in the UK. The development of icing software in my country started from 20 years ago. The more typical freezing software includes NUAA-ICE3D developed by Nanjing University of Aeronautics and Astronautics. The CFD method is used to calculate the air field, and the Euler method is used to calculate the water drop field. Thermodynamic analysis model can calculate two -dimensional and three -dimensional freezing. The common freezing value calculations such as Lewice and Fensap-ICE are not accurate, and their convergence needs to be improved. The establishment of the freezing and icing value platform in my country is not sufficient, and the three -dimensional freezing value simulation method still has many difficulties that require breakthroughs. Aerolab, a San-dimensional complexyfirming prediction, has fully independent intellectual property rights for three-dimensional complex configuration prediction. The software consists of four modules: the grid automatically generates, the air flow field is calculated, the water drop field Euler calculation, and the icing thermodynamics analysis, as shown in Figure 5. The software uses the flow field shiny, the second-order MUSCL space discrete, and the LU-SGS hidden time promotion and other methods to improve the value stability. In the icing thermodynamics analysis module, Aero-ICE software has the MESSINGER and Myers model at the same time, and the wall temperature estimated by the MESSINGER model is used as the boundary condition of the Myers model, thereby solving the experience of the temperature setting of the MYERS model. The ice height predictive accuracy is increased by 6%relative to Lewice. Aero-ICE software also supports multiple grids, multiple grid acceleration technology and large-scale parallel computing.

Figure 5 AERO-ICE software flowchart and its predicted ice shape

04

The effect of freezing on aircraft performance

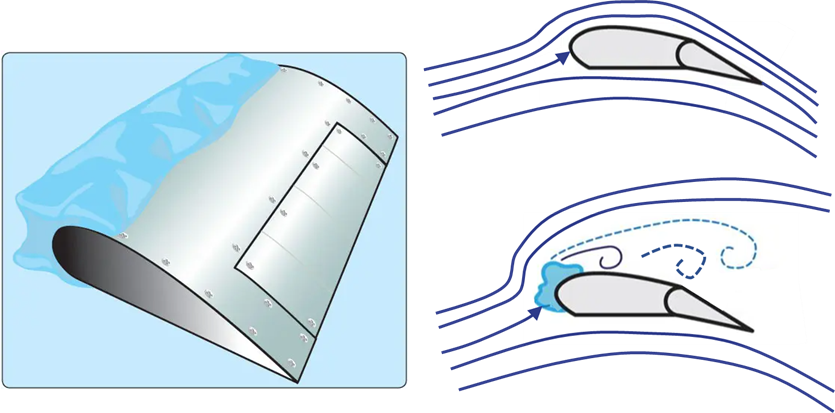

Frozen aircraft will cause the streamlined shape of the lift surface to become a non -streaming shape, which will cause the vortex separation, as shown in Figure 6. The ice in the front edge of the wing will significantly affect the original pneumatic performance, resulting in a significant decrease in lift, a substantial increase in resistance, and nonlinear changes in torque. Sicing also affects the defeat characteristics of the aircraft. After the ice, the aircraft's stall attack angle is advanced, and the maximum lift coefficient also causes large losses, which greatly reduces the red line of the flight.

Figure 6 Sirchemism of the flow field after icing

When the flat tail is iced, its impact on the characteristics of fucking may be greater. The flat tail of the aircraft is a negative lift wing type. During the flight, the aircraft provides a low -headed torque generated by the head of the aircraft to balance the main wing. Because the flat -tailed wing strings are small and the head radius is relatively small. The icing is larger. When the flat tail with ice is working in the negative attack angle, the surface of the lower surface will produce a large flow separation, which will affect the flat ability of the aircraft. When the pilots face the main wing or flat -tailed icing, they need to make different reactions, and they must quickly make a correct judgment even under the complex freezing conditions. When the main wing is frozen, the action that the pilot should do is press the rod and the flap. The purpose of this is to reduce the flight attack angle of the aircraft, increase the maximum lift coefficient of the wing, and stay away from the stall state. When the flat tail is frozen, the response that the pilot should make is the tie rod and the wing wings. The purpose of the lever is to increase the corner of the flat tail to alleviate the separation of the flat tail; The negative attack angle felt in Pingwei increased.

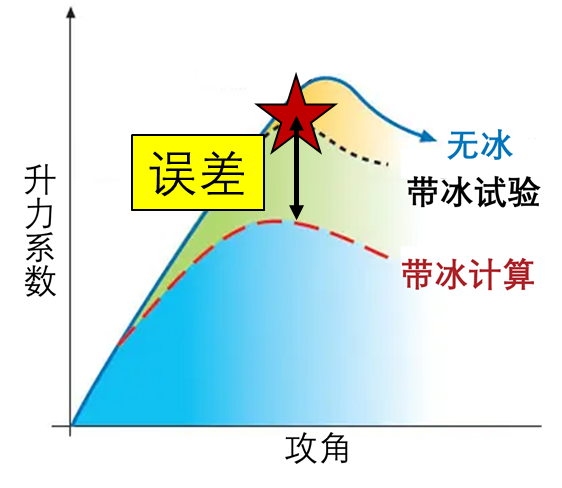

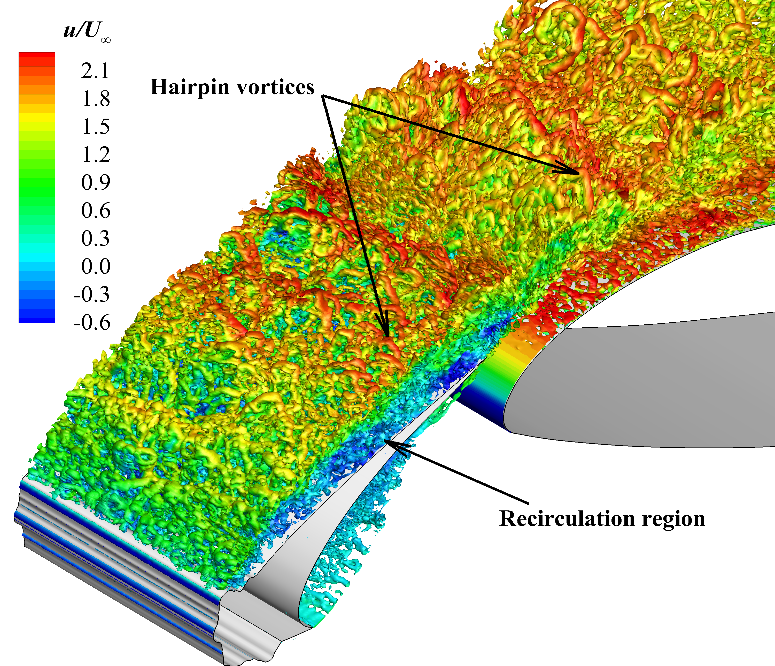

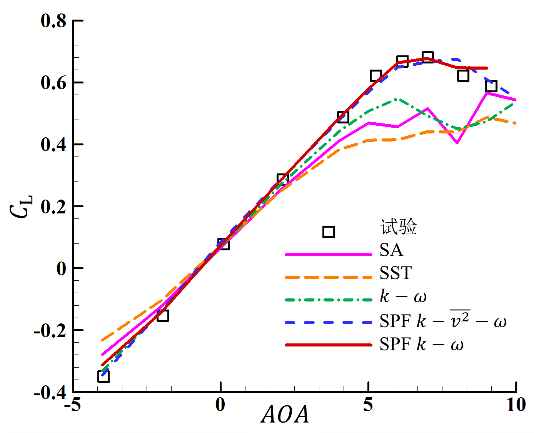

The influence of predicting frozen on the aerodynamic characteristics of aircraft is essentially a large separation flow of predicting non -streaming geometric geometry. A large number of studies have shown that the numerical simulation accuracy of the separation flow depends mainly on the turbulence model, and the traditional Rans (Renault average) model is used in the attachment stream, and it fails to be completely included in the strong inverse pressure gradient. The non-balanced characteristics of turbulence, which makes the existing project unable to accurately simulate the icing separation flow field with the RANS method. The prediction error of the maximum lift coefficient in the key indicator in the airline is even as high as 20%-40%, as shown in Figure 7. The accuracy of the separation of the flow field after icing is calculated by the method of using LES (large eddy simulation). As shown in Figure 8, but the LES calculation overhead is large, and it is currently difficult to apply in the daily design cycle of the project.

Figure 7 The lift coefficient error of the traditional RANS method prediction

Fig

In order to achieve fast and accurately predicting the aerodynamic characteristics after the aircraft was frozen. The research team studied the non -balanced characteristic mechanism of the cutting layer of freezing and separation, and developed a new type of RANS model SPF and SPF, which reduced the predictive error of the maximum lift coefficient of the wing type to within 3%, as shown in Figure 9 Show. This model has been applied to the research on the performance of large -scale passenger aircraft in my country, and its pneumatic characteristics prediction results are well consistent with the results of the wind tunnel test.

Figure 9 uses different turbulence models to predict the GLC305 wing type 944 ice -shaped lift coefficient

05

"Rong Jie" ice starts from the source of design

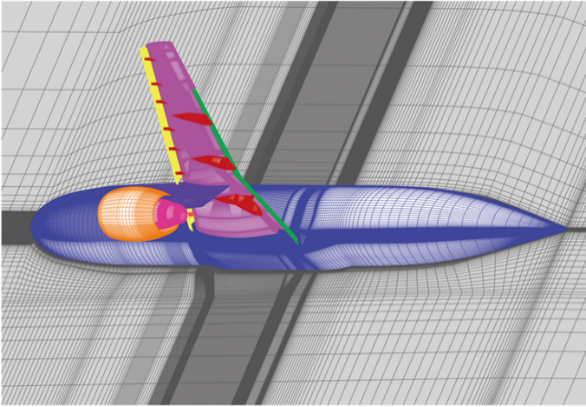

There are three main aspects of NASA's aircraft ice prevention planning: one is to avoid aircraft freezing, the other is to develop freezing aircraft, and the third is to understand the atmospheric state of the aircraft icing. For the development of freezing aircraft, the design unit usually considers the anti -ice and ice removal direction of the wing, and does not consider the pneumatic characteristics after the wing design process. Taking the supercritical wing design as an example, the supercritical wing type is widely used as a wing type widely used by modern civil airliners. Its optimized design system focuses on its performance of the cruise height and speed. The performance during the reduction process, but its aerodynamic characteristics will decrease sharply after the supercritical wing type is frozen, so it seriously relies on the protection of the anti -(except) ice system. During the aircraft design process, due to weight, power consumption, etc., the freezing protection area does not cover all lift surfaces. The icing protection zone of the A320 passenger aircraft focuses on the head of the aircraft: atmospheric data probes, windshield glass, engine anterior edge of the engine, and wing wing section; while the inner wing section of the wing, flat tail control surface, and vertical tail are not protected. Chen Haixin, Zhang Yufei, etc. proposed a new concept of pneumatic design optimized by the wing Rongbing, and used in the design of large aircraft supercritical wings and drone wings, as shown in Figure 10. There are two main driving factors for the wing Rongbing design. The first is to improve the ice flying capacity of the lift surface of the wing without anti -ice protection. Pressure is guaranteed to fly safety when the anti -ice device has not started or work intermittent. The assessment of Rongbing's design capabilities is also reflected in the availability regulations. When CCAR-25-R4 Appendix C stipulates that when freezing, freezing routes, waiting for freezing, freezing, landing and freezing, "the applicant" Should demonstrate the most critical freezing conditions on the surface of the aircraft and the most critical icing conditions on the surface of the normal working surface of the anti -icing system. " Far) The front unit did not start the aircraft ice prevention system. "

The wing's Rongbing design system does not evaluate the Rongbing capacity separately, but to add Rongbing design to the existing wing high -low -speed collaborative optimization system. While ensuring high -speed and low -speed performance optimization, it meets the Airlines Regulations The requirements for Rongbing's ability, so the optimization of Rongbing is essentially multi -goal and multi -design optimization. It has put forward relatively high requirements for the selection of optimization algorithms and the ability to design the entire aircraft.

The icing of the wing is highly uncertain, the unpredictability of the atmospheric environment, and the diversity of the flight state make Rongbing design must face the problem of robustness. In the selection of Rongbing design points The critical condition or uncertain analysis required by the aviation required. Through the verification of the optimized design and wind tunnel test verification, the large aircraft Rongbing wing has obtained an increase of 8.8%of the maximum lift coefficient with the maximum lift at the cost of less than 1%, and the maximum lift coefficient corresponds to the stall attack angle delayed. 4 ° performance improvement.

Figure 10 Rong Bing optimization

Conclusion

Flying in an environment full of cold water droplets, the aircraft may cause freezing, causing the streamline to be completely destroyed, induced the flow separation, which leads to a decrease in lift, increased resistance, and the stability has deteriorated. Severely causes the aircraft to destroy people. Introduce the mechanism of icing aircraft, and the independently developed AERO-ICE software for three-dimensional complex configuration. Because the traditional RANS model is not fully included in the influence of turbulent non -balance effects, the error of the calculation of the pneumatic characteristics of the Ice rear wing type is very large, and the improved SPF model can accurately simulate. The new concept of pneumatic design of the wing Rongbing optimized design was proposed, and pre -research work was carried out in large aircraft supercritical wings and drone wings.

The turbulence model, freezing computing software, and the Rongbing optimization system introduced in this article have been tested in the design of the aircraft model, which has high engineering application value.

Author | Li Haoran

Capture | Wang Xinyang Luo Yuan

Review | Fu Yujie Chen Xing'an Xu Helin Cheng Zezheng

Reprinted content only represents the author's point of view

Does not represent the position of the Institute of Physics of the Chinese Academy of Sciences

If you need to reprint, please contact the original public account

Source: Tanzhen Technology Review

Original title: Super Critical Wing Rongbing Optimized Design: "Silver Wrap" air catastrophe

Edit: Cloud Kaiye

- END -

The third aircraft carrier in my country is named!

The picture shows the launching ceremony. Xinhua News Agency reporter Li Gang by L...

Live video!Naval task ships have arrived in the east of Taiwan Island to book waters

Data-version = 0 data-vwidth = 1920 data-vHeight = 1080 transcoding = 1 style = wi...