US media: China installation is close to the Americas and Europe twice

Author:Global Times Time:2022.09.20

American "Wall Street Journal" September 18th article, original title: As the labor force decreases, the Chinese factory accelerates the robot's offensive

The number of robots installed by the Chinese factory last year is almost as many as the other parts of the world. As the domestic labor age is reduced, China is accelerating to automate and strengthen the dominant position of the manufacturing industry. According to the new data of the International Robotics Federation, in 2021, the shipment of industrial robots in China increased by 45%year -on -year. China accounted for almost half of the total installation of global heavy industrial robots. Twice.

From the perspective of the popularity of robots on the production line, China still lags behind the manufacturing power of the Meridians. China is increasingly aware that as domestic cheap labor supply has decreased and wages have risen, factories need to adapt to new reality. By using more robots, the Chinese factory not only fills the increasingly expanding labor market gap and reduce costs, but also reduces Western companies to relocate production lines to other emerging markets.

In 2021, the output of each working hours in China is 1/4 of the average level of the Seven -Kinged Group's advanced economy and 1/5 of the United States. Many young laborers are now reluctant to work in factories, but are engaged in more flexible work in China's expanding service industry. In addition, China's domestic population migration boom is coming to an end.

In addition to helping to resolve the pressure brought by these changes, automation also helps Chinese factories more focused on carrying out higher -end manufacturing tasks. Such tasks exceed the accuracy that most humans can control (as shown in the figure). At the same time, the robot itself has become cheaper and more adaptable.

A small robotic arm manufacturer in Shenzhen has developed a robot system for customers, which produces wireless headphones for Apple. The company's supervisor said that the team consisting of four workers can complete about 650 headset boxes per hour, while the robotic arm can handle 800, "automation is an inevitable trend."

Despite the expansion of the Chinese robot industry, most industrial robots installed last year were made of overseas, mainly made in Japan. Okiko, the head of the Japanese Robotic Manufacturer Anchuan Electric China Company, believes that the speed of China's use of robots reflects that companies are willing to try new technologies.

The economic benefits brought by the changes in the labor market and the improvement of robotic technology means that China may be entering the boom period of robot application. It is expected that the industrial robots on the Chinese production line will reach 3.2 million to 4.2 million by 2030. The experience during the epidemic also highlights the advantages of automation. Beijing advocates reducing dependence on overseas markets and expanding the proportion of local companies in global supply chains. Susanna Biller, Secretary -General of the International Robotics Federation, said that robots are essential to achieve the goal.

Click the picture link to read the digital poster!

Author Jason Douglas, translated by Ding Yan

- END -

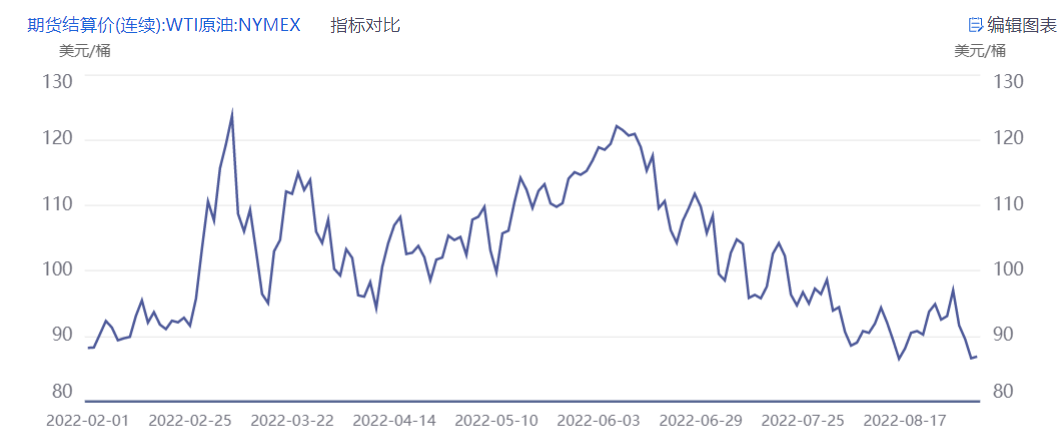

Oil price "five consecutive declines" rose first!From 24:00 on the 6th, the prices of stopping and diesel will increase by 190 yuan and 185 yuan per ton, and the owner will spend about 7.5 yuan more for a box of oil

After two and a half months, the price of domestic oil products rose again.On Sept...

Slow traffic, standard leading -shared electric car comprehensive management series group standards are officially released

On September 9, 2022, the standards of shared electric vehicles were officially released. This series of standards lasted for one year. , Xin Neng'an Technology, China Science and Technology Standard...