Industrial Internet Small Frame Explor ④ | Equipped with the "Digital Intelligence" engine, this car intelligent factory Nissan up to 1408 units

Author:Qingdao Daily Time:2022.09.19

With the maturity and application of new generation of information technologies such as 5G, artificial intelligence, digital twin, and big data integration, the production of low -end intelligent manufacturing of production is less, automated, and flexible. In the intelligent factory of FAW-Volkswagen East China base, all production equipment in the four major workshops of welding, painting, stamping and total installation of four major workshops has been connected. Or the Audi A3 is offline, and Nissan has a maximum of 1408 units. 2022 The fourth issue of "Industrial Internet Small Frames" focuses on the automotive industry, and see how FAW-Volkswagen Co., Ltd. Qingdao Branch promotes intelligence with digitalization to cultivate new kinetic energy with intelligence.

More efficient, production and logistics achieve highly automated

At the beginning of the establishment of the factory, FAW-Volkswagen East China Base actively responded to the "Made in China 2025" strategy, becoming the most high-tech and automatic intelligent factories in the industry. The company also invested about 40 million to 50 million every year for the intelligent upgrade of the factory, and production and logistics have achieved high automation. At present, the intelligent factory produces a total of three models: Pokémon and Audi A3 hatchback and sedan. The welding automation reaches 93.8%, ranking among the top domestic in China, and painting automation ranks first in the automotive industry in East China.

For the safety of the car, the tightening state of the car parts is a key part. FAW-Volkswagen East China base adopts German Volkswagen's most advanced tightening network system to automatically obtain tightening tasks, monitor the entire process of tightening, and automatically storage and preservation of the tightening data, so that the tightening result can be traced back. It is the first to introduce the automatic gearbox suspension, spring legs and rear tailing, which combines digitalization and automation. The whole process does not require manual intervention.

The intelligent production process of vehicles is not enough to rely on the factory itself, and the delivery of daily logistics parts is also very important. Through digital transformation, FAW-Volkswagen East China base logistics has realized the timely supply connection with the supply chain enterprise in the park. Suppliers can view base inventory in real time and replenish them on time as required. The logistics internal logistics in the factory is issued by the production network to send the delivery instructions to obtain components from automated stereo warehouses. The 197 AGV cars are intelligently distributed, and the logistics parts are automatically delivered to the production line.

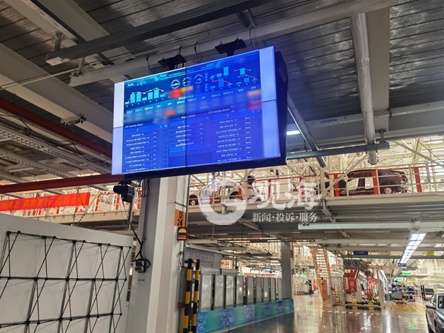

More flexible, workshop equipment achieves 100%networking

In addition to high automation production, the smart factories of FAW-Volkswagen East China base also realized the interconnection of information. "The information of the vehicle is automatically flowing in the four major process workshops. Everywhere you go, you will automatically read the production, configuration, quality and other information of the vehicle in real time to achieve flexible production." FAW-Volkswagen East China base batch planning and industrial engineering department Manager Chen Zhanpeng introduced that the equipment of all production workshops achieves 100%networking, and data collection and analysis are performed. On the other hand, the status of workshop equipment is integrated into the central control room through the industrial network to conduct digital management of the equipment. It can predict the equipment failure in advance and deal with the problem as soon as possible.

It is understood that on the basis of highly intelligent factories, FAW-Volkswagen East China base increased by 5.2%in 2021, and production efficiency reached 30%of the global automotive industry. Through intelligent and automated transformation, manpower investment decreases, which can save more than 24 million per year. At the same time, digital means can also effectively reduce human errors and greatly reduce quality defects. The thousands of failure rates of the Balai model of the base are the lowest in the entire Volkswagen brand model.

Equipped with the "Smart" engine, the Qingdao automobile industry will promote the digitalization, network, and intelligent upgrade of automobile manufacturing, and travel a new path of transformation and development. (Qingdao Daily/Guanhai Journalist Text/Liu Qin Video/Yin Yawei Wei Yixuan Liuqin)

Related Links

Four new navigation, micro perspective shows the road of Qingdao Industrial Internet energy level jumping

The "Four New" boosted that the industrial Internet of Qingdao has entered a new stage of industrial cultivation and empowering development. This pair of "digital hands" of industrial production equipment and people and data are spawning the continuous and innovative and integrated application of innovation, and promoting intelligent manufacturing towards deeper and wider fields.

In 2021, under the support and guidance of Qingdao Industry and Information Technology Bureau, Qingdao Daily Guanhai News Journal Gathering Daily Micro -trending resources jointly launched the lightweight original video column "Industrial Internet Small Frame Detective" to visit Qingdao Digital Zhi ZhiThe transition benchmarking enterprise has more than 20 million views of the three seasons.In September this year, 2022 "Industrial Internet Small Frame Exploration" upgraded with the virtual IP image "small frame probe", focusing on industrial Internet platforms, smart factories, digital workshops, automated production lines, and Qingdao 5G "Top Ten Scenario Demonstration" project andThe "Top Ten Scenario Demonstrations" project of artificial intelligence vividly presents the road of industrial interconnection energy in Qingdao from a micro perspective, and promotes the "Gongfu Qingdao" action to continue to go deep.

- END -

There are 4S shop orders surged, and 10 million -level car consumer coupons were put in many places.

The recent sales volume of the domestic automobile market has continued to pick up...

"Beautiful Shanxi Ecological Line (Yellow River)" Special report (2) There is a demand for market demand for production to guide the new and old and the Grand Canal's heavy card.

The Grand Canal Group started from motorcycle production and started to the storm....