Yawan high -speed rail high -speed EMU is offline!China's high -speed rail towards the world!Shandong "Intelligent Manufacturing", Chinese business card →

Author:Light news Time:2022.08.16

Together with the Central Radio and Television Terminal and the Ministry of Industry and Information Technology, a large -scale financial media reported by the Finance and Economics Center reported "Intelligent Manufacturing China" and entered Shandong Province today. Shandong is one of the most mature provinces in the domestic commercial vehicle industry chain, with complete upstream and downstream facilities. Nowadays, many companies in the industrial chain have built their own smart factories, and the technical level of products has been continuously improved.

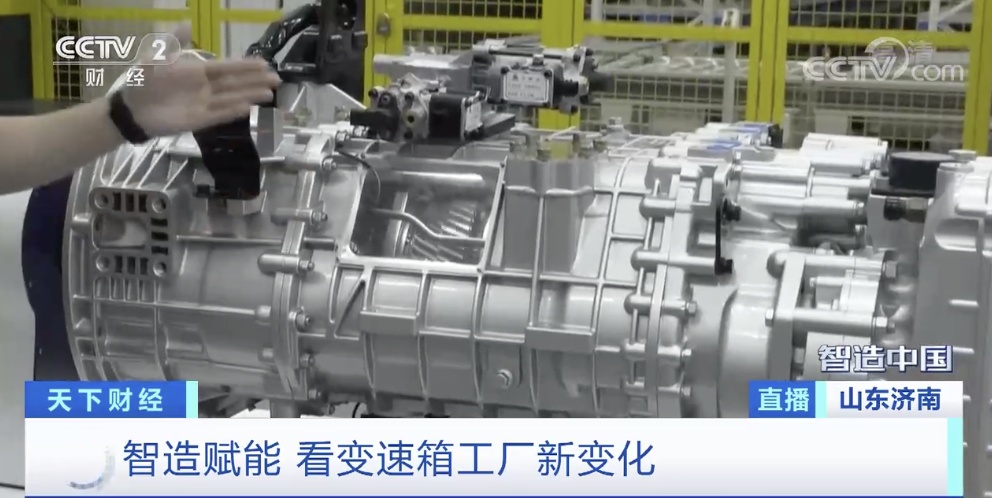

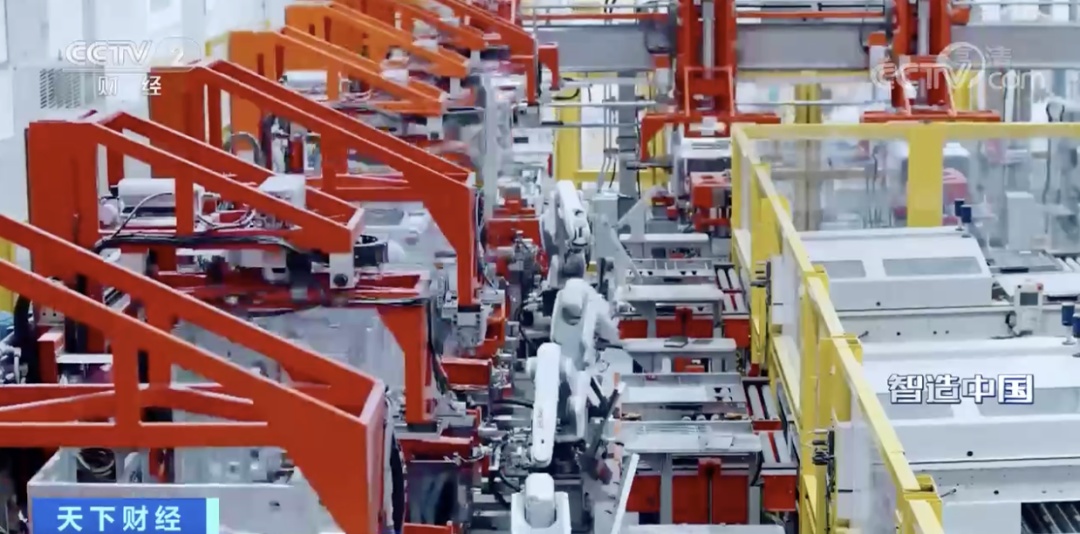

Intellectual manufacturing and empowering the new changes in gearbox factory

The reporter came to a smart factory in Jinan, Shandong, Shandong. The gearbox is one of the three major tanks, which is used to coordinate the engine speed and the wheel driving speed. The picture below is a automatic gearbox produced here. You can see that there are many gears of different sizes in it, and work with each other to adjust the speed. Such a guy weighs more than 300 kilograms, and more than 260 parts must be used.

How to precisely distribute them to various stations? This is inseparable from smart warehousing and logistics systems. In a three -dimensional warehouse, the machine will take out different parts back and forth according to the needs of the birth line and put them in the tray, and then transmit it through the conveyor belt. These AGV logistics cars at the scene are just like the "disabled" in the restaurant, sending the component tray to different locations on the production line.

How do these cars find their own route? There are many QR codes on the ground. The car recognizes these QR codes through the camera on the body and comes from driving. After the distribution of the parts is in place, the robotic arm in the middle of the operation island will be taken to the surrounding stations, and then processed in order, just like a "chef" on the surrounding "chopping board" "" case board "" " Operation".

Intelligent manufacturing technology can improve production efficiency and ensure the safety of production. In such a workshop, from logistics to all aspects of production, intelligent manufacturing is everywhere.

The reporter continued to observe the assembly and matching links of the gearbox. Unlike the traditional assembly line, these gearboxes are lifted through mechanical cantilever and automatically rotated around the production area. Flexible configuration and processing can be performed in different locations.

Here, you can see two models. The left on the left was the earliest "Yellow River" heavy truck. It was the first heavy truck produced by New China in 1960. At that time, its load was only 8 tons. The right side was the latest "Yellow River" heavy truck. It can already reach 49 tons.

The advanced unmanned driving heavy card displayed on the screen has been actually put into use in Tianjin Port.

Looking at it step by step, everyone can clearly feel the progress of my country's heavy truck manufacturing capabilities; the key links in this industry chain are also moving in the direction of intelligent manufacturing like the transmission production today. In the future, it is even more worth looking forward to.

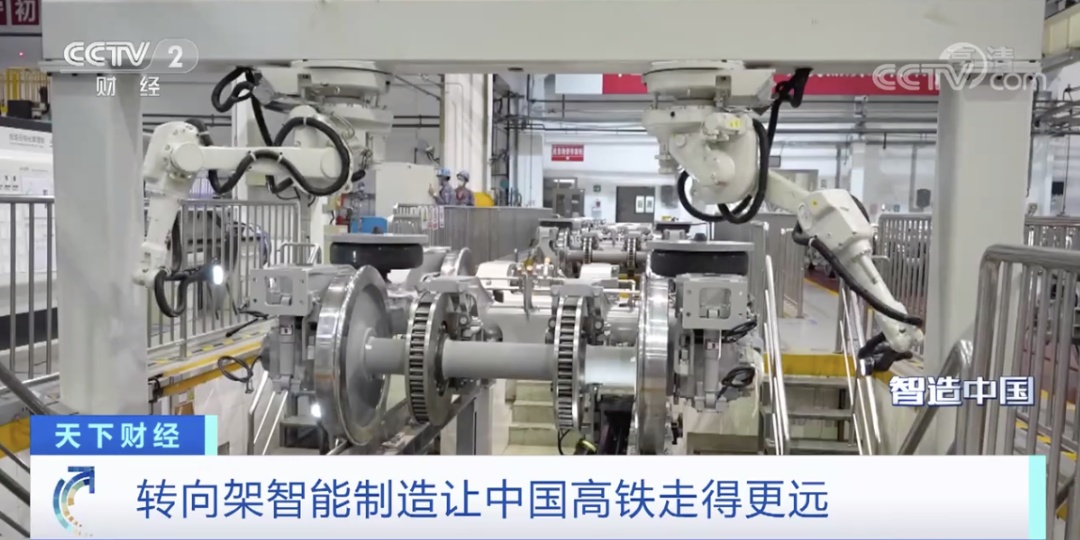

Intelligent manufacturing of the steering frame allows the Chinese high -speed rail further

Earlier this month, my country ’s first overseas high -speed EMU -Yawan high -speed rail high -speed EMU was launched in Qingdao. Engineer Deng Hongjian participated in the intelligent manufacturing of this high -speed EMU steering frame. Deng Hongjian witnessed the role of China's high -speed rail from "chasing" to "leaders". In his eyes, what new changes bring to traditional manufacturing?

Deng Hongjian, an engineer of the technical engineering department of CRRC Sifang Co., Ltd.: This train will soon be shipped to Indonesia. Our technical team is mainly responsible for the most critical component of the train. Move, we complete the production of the entire junction through intelligent manufacturing.

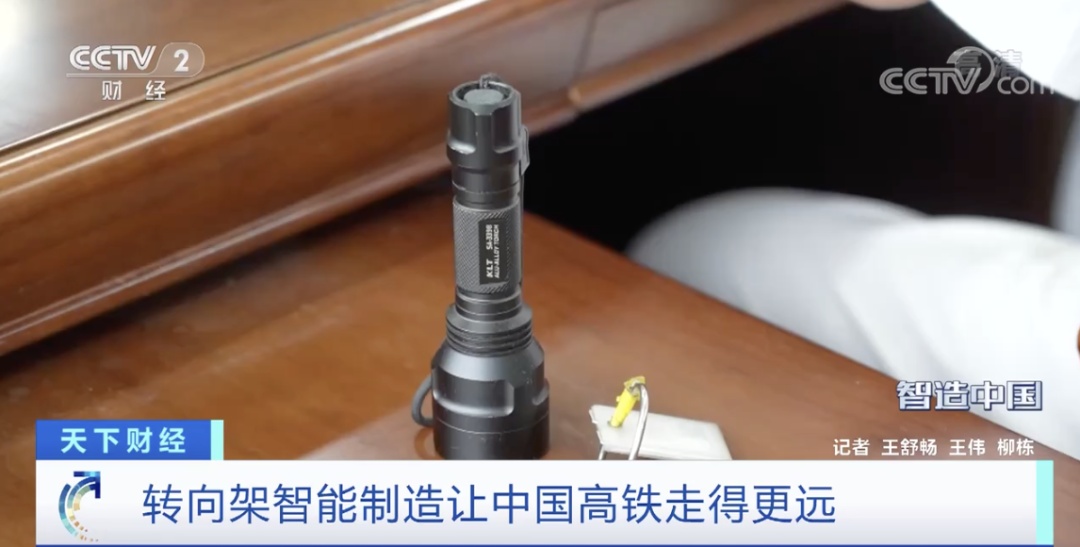

Speaking of intelligent manufacturing, Deng Hongjian's face is proud. On his desk, there was an old flashlight and a steel sheet. Deng Hongjian said that these two old objects were once necessary tools for production, and now it is a memorial and a spur.

The noise and iron dumbs caused by artificially polishing are very harmful to workers' bodies. After the intelligent upgrade, the factory has an automatic polishing device. The device can model the workpiece, and then compare with the target model. Finally, the automatic polishing program is turned on. The polishing accuracy can be controlled at 0.5 mm.

Deng Hongjian, an engineer of the technical engineering department of CRRC Sifang Co., Ltd.: In terms of efficiency, it has a great improvement. People may have to complete the workload for three hours, and it can be completed in half an hour with equipment.

The test of manual polishing is the strength of the hand, and the artificial test tests the accuracy in the eyes. The last process before the steering frame was out of the factory was that the workers took the flashlight for inspection, and now this smart image collector can take photos around the parts of the steering rack. Even 1 mm error can be seen clearly.

Deng Hongjian, an engineer of the technical engineering department of CRRC Sifang Co., Ltd.: 15 minutes can complete a steering frame test, and the quality inspector may take half an hour.

Deng Hongjian is the first batch of technicians to participate in the production of high -speed rail EMUs. The high -speed rail EMUs who produce independent property rights are his dreams. From following foreign experts to learn technology, to China's technical standards to land abroad, he witnessed and participated in the role of the Chinese high -speed rail from "chasing" to "leaders".

Building network with equipment "from point and face" promotes the development of intelligent manufacturing

Shandong Province is a traditional industrial province and strong economic province. In recent years, Shandong has continued to promote the conversion of old and new kinetic energy, and has continuously transformed and upgraded in the direction of intelligent manufacturing. Building a good network infrastructure and cultivating and promoting intelligent equipment. Today, Shandong has created a number of intelligent manufacturing benchmark demonstration factories, which is driving the overall upgrade of the industrial chain. What specific practice and experience does Shandong have in intelligent manufacturing? The reporter interviewed Ling Wen, the deputy governor of Shandong Province. Walking into a smart factory in Jinan, Shandong, with the help of 5G networks, the logistics AGV car and industrial robotic arm on the scene can be organized in an orderly manner.

Lingwen, deputy governor of Shandong Province: We match 5G and fiber to the extreme, and now we have built 133,000 5G base stations; the fiber has a total of 5,600 kilometers, and the delay of any two cities can achieve within 1 millisecond. Including industry, ports, transportation, civilian use, all facilities can achieve the best intelligent communication.

After the equipment information is connected, each production line can produce a variety of different products at the same time, and a large number of flexible production can be realized. With the help of various types of intelligent equipment, the number of employees in the factory only requires an original quarter.

In recent years, Shandong has focused on production positions with high labor intensity and high dangerousness, promoted machine substitutions, and accumulated more than 300 "first sets" intelligent manufacturing equipment. In the first half of this year, the output of industrial robots in Shandong Province increased by 33.1%year -on -year.

Lingwen, deputy governor of Shandong Province: The most basic unit of intelligent manufacturing is every equipment. For example, many of the more advanced intelligent chemical plants in our province have reached about 95%of the intelligent equipment.

Ling Wen introduced that after creating a group of intelligent manufacturing benchmarks, Shandong is now promoting the integrated intelligent upgrade of the industrial chain, and "from point and face" formed an ecology.

In fact, it is not easy for Shandong to achieve such intelligent transformation results. In the past, Shandong's industrial structure was famous for "two 70%": traditional industries accounted for about 70%of the industry, and the proportion of heavy industries accounted for about 70%. In order to promote the transformation and upgrading of traditional industries, Shandong continued to increase investment in technological reform. From 2020 to 2021, the average increase in investment in Shandong's technical reform increased by 6.4%, and the scale of technological reform investment ranked among the top in the country.

Ling Wen, deputy governor of Shandong Province: Old industries, we must use intelligence, digitalization, and industrial Internet to empower them. Shandong is the largest province with chemical industry. First, let the chemical plant be concentrated into the park. All the cans are equipped with sensors to early warning and investigation of hidden dangers to ensure the safety and high -quality control operation of the device. On the one hand, we will resolutely promote these application scenarios and good experiences on the one hand, and also spend a lot of energy to support, promote, promote, and guide small and medium -sized enterprises to achieve intelligent manufacturing of the entire society.

Source: CCTV Finance

- END -

Weifang created "East Asian Cultural Capital" | "On the chain" Qingzhou, helping the industry take off

Recently, the Weifang Emergency Safety Industry Alliance was established. Shandong...

remind!Summer vacation practice "Auto Black Technology Experience Officer" is appointment and arrives on time on time

The first stop of the summer vacation, do social practice first! Since the officia...