Accelerate domestic replacement, 3D printing high -thermal heating mold steel material trial production

Author:Yangcheng Evening News Yangche Time:2022.09.21

Text, Figure/Yangcheng Evening News all -media reporter Yu Xiaoling correspondent Huang Yali

The middle test, that is, intermediate test, refers to the process of using the condition that is basically consistent with the production of production after completing a series of process research in the laboratory. It is a necessary link for the transformation of scientific and technological achievements to productivity. A few days ago, the reporter learned from the Everbright WE Valley of Songshan Lake in Dongguan in Dongguan. Try production. The research and development of this material for high -end industries such as aerospace, automobiles and industrial molds, and rely on major projects of provincial and applied foundations. In the future, it is expected to be applied in the fields of consumer electronics, medical care, and automotive molds, which can achieve cost reduction and efficiency and accelerate the transformation and upgrading of Dongguan mold manufacturing.

Enter the mid -testing stage to make mold production "calm and efficient"

The Everbright WE Valley · Yanyan Technology Park was jointly created by the Dongguan Materials Gene Higher Institute of Technology and Guangdong Everbright Group. It was officially opened in June this year. The science and technology park will take the new material industry as the core to create a center of technology-research scientific and technological achievements, and realize the full coverage of "basic research-application research-industrialization development".

Among them, in terms of the transformation center of the scientific and technological achievements of industry, university, and research, Guangdong Everbright Group will integrate a new scientific research institute in the link to build a connection platform for enterprises and innovation carriers to accurately serve the innovation and development of enterprises. Do specialty, refine, and strengthen, and enhance the advantages of the added value and comprehensive competition in the industry.

Dongguan Materials Gene Higher Institute of Technology Research Institute Zeng Material Manufacturing Center is located in the Chinese Test R & D Zone of the Science and Technology Park. It is an important platform for promoting the transformation of scientific and technological achievements in industry, university, and research. The center is mainly for Dongguan manufacturing enterprises, especially the mold industry with a strong foundation for Dongguan, which provides high -conducting new materials in the mold industry, and injects the strongest technology into the development of the industry.

Add material manufacturing center invested multiple professional equipment to develop new materials

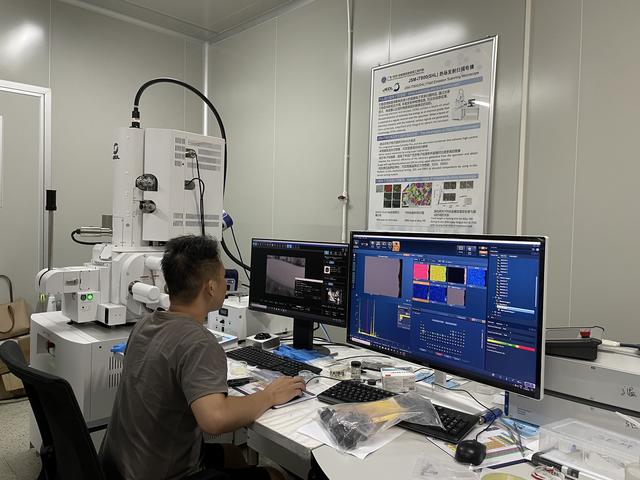

How to develop a new high -thermal heating material? The reporter entered the additive manufacturing center. The first thing to see was a metal 3D printer, research -level golden display microscope, field launch scanning electron microscopy, FIB field launch dual -bundle scanning electron microscope and Luoshi's hardness meter. "These equipment cost more than 20 million yuan, which provides necessary conditions for the development of new materials." Li Xiangwei, director of the Zeng Material Manufacturing Center, said that it is necessary to develop and prepare high -guide powder materials that meet the needs of industrial production. , Matching the high thermal conductivity, and the cost requirements faced by large quantities of production. This requires starting from the design of material components. With professional R & D equipment, optimizing the preparation process, improving micro -organizations inside the material, and improving the mechanical properties of materials.

3D print high -guide hot powder material

Since 2019, the team of more than 10 people has entered the "China Test" stage after three years of research and development. "At present, high -guide thermal powder materials have been produced by hundreds of kilograms of production, and cooperated with a leading enterprise in Guangdong to use metal 3D printing technology to achieve the preparation and verification of high -heat -conducting cooler cooling molds." Li Xiangwei said.

The mold is known as the "mother of industry" and plays an important role in industrial production. The temperature of the mold not only affects product defects, but also consumes long-term cooling, accounting for 60%-70%of the entire injection molding cycle.

Researchers operate the machine for powder 3D printing

The research and development of high -heat -conducting materials at the Zeng Material Manufacturing Center will promote the transformation and upgrading of the Dongguan mold industry. "High -conductive 3D printing with cooler cooling molds can improve the temperature balance of the mold, reduce injection molding cycle, improve production efficiency, and significantly improve the quality of product quality and the service life of the mold." Li Xiangwei said.

Whoever masters the materials will master the future. After entering the mid -testing stage, with the significant increase in the amount of new materials, the technological achievements of the additive manufacturing center will accelerate, helping the Songshan Lake Science City to build a full -chain and full process of the full -factor science and technology ecosystem.

Take the national, provincial and ministerial projects, accelerate results transformation and technology implementation

In 2019, Li Xiangwei, a doctor of Chinese University of Science and Technology, came to Dongguan. As the person in charge of the metal additive manufacturing team, he continued to engage in the research of new metal materials at the Dongguan Materials Gene Higher Institute of Technology and seeking technical application scenarios.

In Li Xiangwei's view, the new material enters the test stage. Finding the matching application scenarios in Dongguan is an important part of R & D work and the recent goal. The vision of the additive manufacturing center is still farther -in high -end fields such as aerospace and automobiles, accelerate the development and technology implementation of new materials.

Since 2010, Li Xiangwei has been engaged in the research and development of high -temperature alloy materials in aviation engines, which has exceeded 10 years, and has a deep knowledge of industry development.

In the field of metal 3D printing, around 2013, foreign imported equipment and materials are mainly based on. In recent years, with the maturity of domestic equipment and powder materials technology, localized alternatives have gradually been achieved in the fields of handboard processing, mold manufacturing and aerospace. In the future, with the further reduction of the cost of the industrial chain, metal 3D printing will gradually change from prototype manufacturing to batch production. However, in the process of mass production, it will also involve problems such as the development of new materials and the deformation control of parts caused by residual stress, and high -efficiency and low -cost printing process. They will delay the arrival of the batch production era, and it is also a challenge facing the additive manufacturing industry. This has also become the current status of the industry that Li Xiangwei will be broken in the future.

"At present, for the needs of high -end fields such as aerospace, automobiles and industrial molds, high -throughput calculations are used to combine with machine learning methods to promote new metal increases such as high -temperature conductive mold steel, high -temperature alloy, high -strength aluminum alloy and high tough tough titanium alloy. The research and development of special materials for materials manufacturing. "Li Xiangwei said that in the future, it is necessary to continue to increase research and development, assume the mission and responsibility of a scientific researcher, promote the development of high -end metal powder, and accelerate the advent of the batch production era. Researchers conduct new materials research

At present, the team undertakes 7 scientific research projects, including national key research and development plans, major basic projects in Guangdong Province, and Yueguan Fund. In particular, the Institute of Research Center in 2020 led the Materials Manufacturing Center, and academician Wang Huaming team of Beijing University of Aeronautics and Astronautics, a key college in the United Nations Academician Yan Qingyun's team of the University of Hong Kong, for the common basic scientific issues of long -term restricting the development and application of metal components, the development and application of the development and application of the manufacturing and application of metal components, and carried out the mechanism research of melting pond metallurgical dynamics and internal defect formation mechanism, the internal stress formation and regulation of materials manufacturing, and the new high -performance high performance 5 aspects of the development of additive manufacturing materials.

In addition to the additional material manufacturing center, the complete material development, preparation, representation and detection instrument facilities of the Yiyan Technology Park are also set up, and professional R & D centers such as stress engineering centers, micro -organization representation centers, and structural integrity centers are also set up. In the future, Yanyan Science and Technology Park will build a unique new material industry ecosystem, build a collaborative innovation center and high -end knowledge -intensive industrial platform for new material technology, and promote the vigorous development of the new material industry in Dongguan and even the Greater Bay Area.

Source | Yangcheng Evening News · Yangcheng School

Responsible editor | Feng Xiaojing

School pair | Peng Jiye

- END -

The 2nd China New E -commerce Conference opened in Changchun

Today (July 29), the second China New E -commerce Conference opened in Changchun. ...

On the first day of the public opening of the public, the on -site activities were high!

Yesterday (September 3) was the first day of the public opening day of the service...