New breakthroughs in biological 3D printing!Myocardial tissue can survive for more than 6 months

Author:China Popular Science Expo Time:2022.09.05

Biological 3D printing is a very novel and interesting application in the 3D printing technology revolution, but so far we are still unable to prepare complex organizations that have physiological functions and can survive for a long time. However, from the Institute of Genetics and Development Biology of the Chinese Academy of Sciences and Tsinghua University, the joint research team of the two units broke through the relevant technical bottlenecks and successfully printed myocardial tissue with in vitro. The results have been released online in February this year.

(Image source: References 1)

Biological 3D printing is an emerging technology that uses 3D printers to print biological ink containing cells, growth factors and biomass materials. What are the places worth exploring this technology, and how do Chinese scientists have made a breakthrough? Let's take a look.

1. One of the difficulty of biological 3D printing technology -biological ink

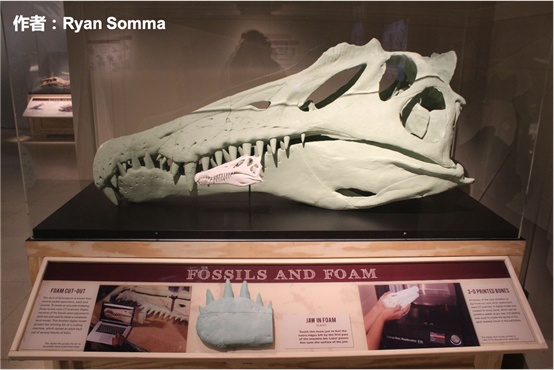

The medical industry has focused on the 3D printing technology of organ organizations since 2014. The most known of which are mainly used to make fillers with metal, ceramics, plastic and other materials to repair the hard human body such as bones. In addition, 3D printing technology can also be made into a silicone model of the heart and other organs, so that the surgeon can study the therapy or conduct drills before formal surgery.

The 3D printed drain bone (two sizes) printed after scanning of the computer fault (two sizes) (picture source: Wikipedia)

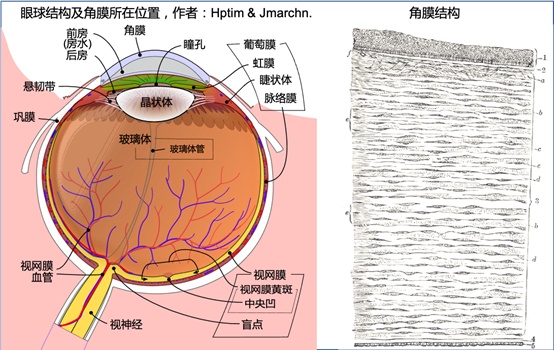

After that, with the development of biological 3D printing technology, how to choose appropriate materials and processes to achieve the organization and organs that need to print the skin and cornea that require both biocompatibility and high requirements for softness and toughness. Today's research hotspots. At the same time, the new concept of biological ink has gradually entered everyone's vision. One of the most critical technologies to print human organs is the raw materials for 3D printing, that is, biological ink.

In the current biological 3D printing technology, the separate cells themselves cannot act as printing materials, so some special substances need to be used as the substrate to support cell survival. After the matrix is fused with the cells, the mixture is sprayed from the nozzle of the printer for printing. This mixture is the biological ink (sometimes the biological ink also refers to the matrix itself). Depending on the method of system and raw materials, the performance of biological ink is also different, but most of the ingredients are hydrogel containing stem cells. Bio -polymers based on collagen, glue, hyaluronic acid, ligaidate, and nano -plant cells are used as the basis of biological ink. It has good biocompatibility and is easy to print 3D. The printed structure can imitate the true interconductor matrix, which also makes it possible to print a complex three -dimensional tissue structure.

The scope of application of 3D biological printing (from molecular, cells to tissue and organs) (picture source: reference document 2)

The biological ink has high requirements for materials, and the following three points must be met to print a suitable organization. First, cell compatibility to maintain the vitality of stem cells. Second, the appropriate hardness is to keep the shape of stem cells. Third, suitable softness and viscosity to ensure that it can be sprayed out by the nozzle of the printer.

In order to meet these requirements, scientists have continued to practice. In 2017, Swiss manufacturers launched a new type of synthetic biological 3D printing ink. Its main component is hydrogel, which can provide a three -dimensional peptide nanofiber bracket to promote cell growth and movement. After that, the research team of the Composite Materials Laboratory of the Federal Institute of Technology in Zurich has developed a 3D printed biological ink containing different types of bacteria. According to the characteristics of various types of bacteria, it can be applied to skin transplantation, chemical degradation, etc. field. In 2019, the University of Newcastle University successfully printed the human cornea with biological ink, and the entire production process was less than 10 minutes. Researchers mixed the stem cells from healthy donors with algate and collagen to create this new type of biological ink.

Even corneal has a very complicated structure (picture source: Wikipedia)

Second, the two of the biological 3D printing technology -printer

In addition to high requirements for biological ink, 3D printing tissue organs also need to be able to cooperate with the printer used. In 2016, a Swedish company launched a special 3D printer using biological ink. The supporting biological ink they developed is based on nano cellulose. This material provides a structure similar to extracellular matrix, which can mix cells and ink printed. The 3D printer only needs to be printed first first, and then cross -collapse the printing structure.

Most 3D biological printers adopt a special structure, which also allows the shock of cell activity to minimize the impact of cell activity during the drip jet process. The nozzle diameter of the printer is generally between 150 microns and 2 mm. During the printing process, the cells or molecules are kept liquid. After printing, it can be solidified for a short time, showing a viscous elastic state. This fluid to solid -state changes can minimize damage to cells, biological activity factors, and other particles, ensure the survival of cells, and is conducive to in vitro culture. During the printing process, the biological ink needs to be printed on the biological bracket. After printing, the bracket can not only play a role in maintaining the three -dimensional structure of the cell mixture, but also maintain the growth and survival rate of subsequent cells. With the survival of the cells and the formation of tissue, these biological stents can be degraded by themselves.

Third, the third of the biological 3D printing technology -the printing process is very important in addition to the biological ink and printer, and this is the printing process. A good process can maximize the potential of the materials and equipment itself, while avoiding the defects of exposed materials or equipment as much as possible. Many times the performance improvement of materials and equipment will fall into bottlenecks. Of course, the process itself and materials and equipment cannot be strictly separated. Many times the process of process improvement itself will also upgrade materials and equipment.

The biggest problem with the previous biological 3D printing technology is that it is difficult to reproduce the real organizational structure. The printed product is not a three -dimensional organic body, but a group block formed by cell groups. The connection methods between the cells and the position of the cells in the matrix are very casual and loose, which is far from the orderly structure in the real organism. The organs are formed on the basis of the organization. If the organization that is close to the real situation cannot be produced, the 3D printing organs are a more distant dream. However, the new results obtained by Chinese scientists this time have greatly reproduced the three -dimensional structure of the printing organization. The key is the innovation of printing technology.

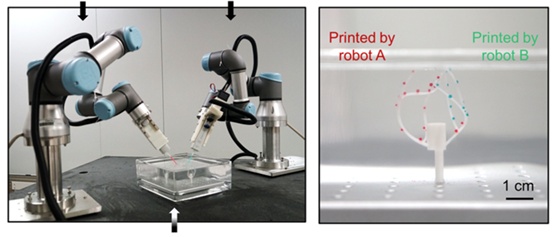

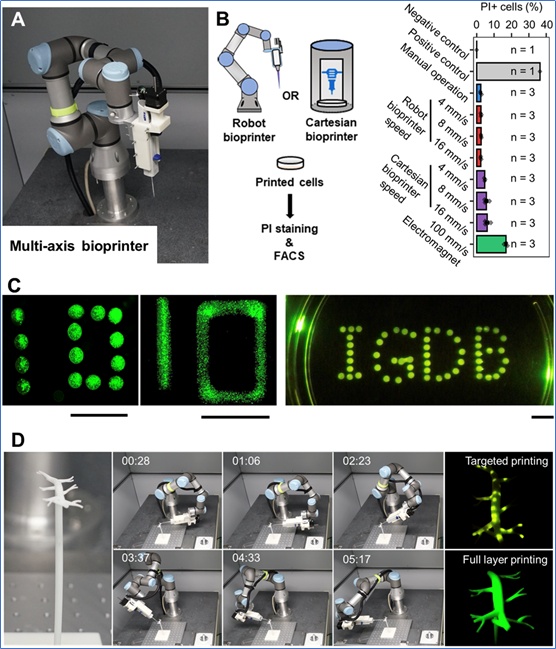

The research team first integrates the design principle of the six -axis robot into the biological 3D printing technology. This robot has six joints that can rotate 360 ° freely. The earth has increased the flexibility of 3D printing. Under traditional technical conditions, the printing process is generally accumulated layer by layer by layer, and cells and vascular networks are difficult to organically integrate.

Six -axis robot specially used for biological 3D printing (picture source: reference 1)

Chinese researchers have redesigned the circular "print-training" process, and do not pursue a formation, adding training processes. Specifically, after printing a few layers of cells on the blood vessel stent, the overall co -cultivation of it for a period of time. After the colonial connection and neonatal capillaries with physiological function are induced between printing cells, a new round of cell printing is performed. Although this method is at a disadvantage in production efficiency, it has an advantage in printing quality. It can not only better reproduce the organizational structure, but also ensure the long -term survival of the printing organization.

After various efforts, Chinese researchers finally developed myocardial tissue with endogenous capillary networks and surviving in vitro. What's more, these organizations can fight in vitro for more than 6 months, showing good physiological activity and application prospects. Applying similar processes to other stem cells and biological ink systems, there is hope to induce and cultivate other human tissues. In the future, the stem cells required for 3D printing will come directly from patients. After transplantation in the body, these autologous cells will not cause immune exclusion reactions, thereby solving the two major problems of deficiencies and immune rejection at the same time.

With the increasing maturity of 3D bioproculation technology, the types of biological ink will also become richer and richer, and the corresponding equipment and materials will also reduce costs. Although the current scientific level of human beings is not enough to directly cultivate human organs in vitro, the results of Chinese scientists have made us take a small step towards this dream. I believe that one day, we can overcome all difficulties, solve the problem of insufficient organ transplants, and benefit all human beings.

Produced: Popular Science China

Author: Li Zhuosi (Doctor of Biology/Professor)

Producer: China Science Popularization Expo

references:

1. A Multi-AXIS Robot-Based BiPrinting System Supporting Nature Cell Function Preservice and Cardiac Tissue Fabrication

https://www.sciencedirect.com/science/article/pii/s2452199x22000743

2. Recent Advances in BIOPRINTING Technology: Approaches, Applications and Future Prospects

https://translational-medicine.biomedcentral.com/articles/10.1186/s12967-016-1028-0

3. [Cellink Society 3D バ イ オ プ リ ン タ ー]

http://www.filgen.jp/product/si/cellink/index2.html

4. [Artificial skin 印 3D printing できる イ オ プ リ ン タ ー を 発 発 発 発 タ タ タ タ タ タ35 points ㎡ 1 square meters of transplantation for skin を possibilities]

https://www.dtod.ne.jp/ward_topics/article82.php

The China Science Popularization Expo is the Science Popular Science Platform of the Chinese Academy of Sciences. It is sponsored by the Computer Network Information Center of the Chinese Academy of Sciences. Relying on the high -end scientific resources of the Chinese Academy of Sciences, it is committed to spreading cutting -edge scientific knowledge and providing fun science and education services.

- END -

The United States restricts high -performance semiconductor exports, which areas will be affected?

Economic Observation Network reporter Shen Yiran on August 31, the U.S. government...

The post -90s guy is obsessed with health, creating their own massage method with cataracts

Science Fiction Network, July 5th (Liu Yazhu) According to Shanhai video report, r...