The long triangle nano research institute uses nano -coating technology to achieve major breakthroughs in oil -free aluminum processing

Author:Hangzhou Metropolis Time:2022.08.20

Recently, a technological innovation that does not seem surprising has made a long -term problem that cannot be solved well. In addition, the tools and work molds after nano -nano -nano -lubricating coating and abrasion -resistant hard membrane layer are increased by a maximum of more than 15 times from the unprocessed life.

Science tells us that the materials and parts of aluminum products and their components are fever and easily sticky during the processing process. Usually, the aluminum profile and aluminum products parts need to be sprayed to the processing during cutting and processing. In addition to the sprayed oil, in addition to the processing equipment full of oil, it will also cause oil pollution in the floor of the workshop and easily lead to the occurrence of production safety accidents. At the same time, because aluminum processing products contain oil, they need to be cleaned repeatedly, which will discharge a large amount of waste water.

Yunhao Nano Technology Team of the Institute of Development of the Yangtze River Delta Nano -Technology Industry Development Research Institute, organizational technical force research, through nano -plated self -lubricating coating and abrasion -resistant ductive plug membrane layer, let the tool processing self -lubricating and non -stick coating technology successfully applied to aluminum processing On the molding tool, work mold. Using this technology, during the process of aluminum processing, good non -sticky and reduced friction coefficient heating, which successfully replaced the tool process that requires cooling lubricants into processing during the process of processing of traditional aluminum.

The application data of leading enterprises such as Jiaxing Youjia Metal Products Co., Ltd. shows that the tools and work molds after nano -self -lubricating coating and abrasion -resistant hard membrane layer are increased by the maximum life expectancy of unprocessed use. After the high -end and high -performance molds imported from Japan, the service life increased by more than 10 times.

Nano self -lubricating coating and abrasion -resistant hard membrane layer reduces the number of workers in the fuel injection process and refueling of aluminum processing enterprises. At the same time, it also improves the environment of aluminum and aluminum products processing workshops. The damage caused by aluminum dandruff caused by strain products to quality has achieved the technology innovation and product innovation of aluminum and aluminum component processing, and promoted energy conservation and emission reduction and high -quality development of enterprises.

Ma Yiyun, the person in charge of Yun Hao Nano, the Institute of Development of the Yangtze River Delta Nanomi Technology Industry Development Research Institute, said that on the basis of the successful application of technology, they will cooperate extensively with aluminum products processing enterprises to jointly test and jointly develop. The technology of wear -resistant hard membrane layers is widely used to aluminum, aluminum product component processing enterprises and aluminum -made tool work mold production enterprises, helping traditional enterprise technology innovation and rapid development of high -end products. (Correspondent Wang Yulin)

- END -

What is taurine? What is it?what's the effect?

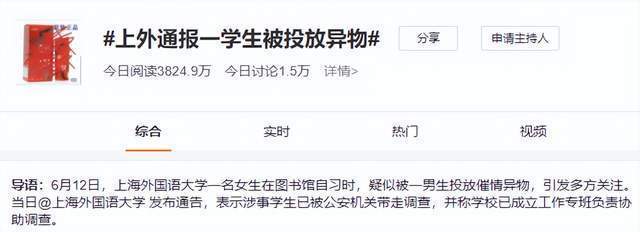

On June 12, a a girl coffee cup of Shanghai Foreign Language University was put on...

Jinjiang Literature City said that the failure has been repaired by netizens: forums and comments cannot be opened

Zhongxin Jingwei, June 27th. Aiming at the official website of Jinjiang Literature...