This little giant company in Wuhan is shortlisted for the Ministry of Industry and Information Technology for Medicine 3D printing

Author:Changjiang Daily Time:2022.08.11

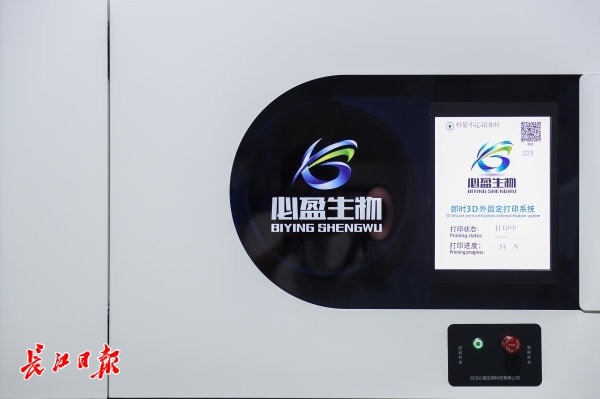

3D printer independently developed by Wuhan Bio. Reporter Xu Wei Wei

The Yangtze River Daily Da Wuhan Client August 11th (Reporter Li Jia) On August 9th, a reporter from the Changjiang Daily saw at the Medical 3D Printing Research Center of Wuhan Biying Biotechnology Co., Ltd. After tens of seconds, the wrist model is automatically drawn on the computer. After 14 minutes, the outer fixed branches of the wrist were printed with a 3D printer.

Recently, the "Personalized Rehabilitation Branch Printing based on human data learning" project was officially selected into the first batch of "list of typical application scenarios" of the Ministry of Industry and Information Technology, and Wuhan must be the first service provider in Hubei Province to be shortlisted for this list.

3D printer (partial) independently developed by Wuhan Bio. Reporter Xu Wei Wei

What is "additive"? According to experts, the method of reducing the product is based on the size and parameters of the design, and a rough part is obtained by cutting the materials through a little bit of cutting, digging, cutting, and carving. The additive is to stack the material powder layer by layer, and then sintering through laser to slow down the product "growing up". The 3D printing is a typical way of adding material manufacturing. Under the precise control of the computer, the materials used are layered according to the design model to turn the blueprint into physical objects.

The self -developed 3D printer printed on the outside of the foot. Reporter Xu Wei Wei

In the production workshop of Bingying Enterprise, the reporter saw that more than 50 machines with "Wuhan Bi Ying creatures" were tested in the factory and final test. Huang Jiatao, director of the 3D Printing Research Center of this company, introduced that the installation volume of this year can reach 200 units. Currently selling fourth -generation products, from digital molding, printing speed, printing range, and printing dimension. Improved, only 3D printing links have shortened to the shortest 8 minutes; the scope of printing is also extended from the original part to the present. The supporting support for rehabilitation, or even avoiding a small wound special branch, can be printed.

The independent 3D printer printed by the hand -fixed branches. Reporter Xu Wei Wei

In the eyes of the public, 3D printing is generally considered "slow". The mainstream technical route of 3D printer is based on melting deposits. The main disadvantage is that the modeling is slow, the printing is slow, and the post -processing is slow. In order to solve this pain point, shortly after the company's start -ups, the company has established a medical 3D printing technology research center with Wuhan University of Science and Technology, from printing materials, software to printers. "One of the main pain points in the market is slow, and the other is poor operation. Modeling, design, production ... For non -manufacturing professional clinicians, the operation is too cumbersome. Essence

Autonomous 3D printer printed by the calf fixed branches. Reporter Xu Wei Wei

In order to achieve fast and easy -to -operate printing, the team absorbs cross -border talents such as clinical medicine, materials, intelligent manufacturing, artificial intelligence, and big data, and the establishment process of data models has been changed from artificial operation to fully automated process. After nearly ten years of research and development, only 10 tons of 3D printing materials used for experiments were used, and computer deep learning exceeded 10,000 cases.

The staff used the scanner to scan the hand. Reporter Xu Wei Wei

Huang Jiatao introduced, "In the end, we adopted the independent research and development software that was later awarded the patent of the national invention, and converted the scanning data into printing data. It only took 30 seconds. , Slice; at the same time, the independent 3D print head can make the material's thickness adjustable and faster print; the polymer printing material is also its own 'exclusive formula'. One -sixths of the weight of the branches, and can effectively avoid the patient's wounds, which is convenient for doctors to observe skin changes. "

The staff operates a 3D printer. Reporter Xu Wei Wei

As of now, Wuhan Biying has obtained 42 independent intellectual property rights and 8 national invention patents. This year, he has also been selected as a "specialized new" giant company in Hubei Province.

A reporter from the Yangtze River Daily observed that the country's first batch of additional materials manufacturing scenarios were collected, encouraging the use of safe and controllable new materials, new equipment and new solutions, shortening the development cycle, improving product performance, reducing manufacturing costs, saving material energy consumption, energy consumption, and energy consumption of materials, and energy consumption of materials, and energy consumption of materials, and energy consumption of materials. Improve production efficiency, and finally "new models and new formats for promoted additive manufacturing formats that can be promoted."

The staff uses the computer for model processing. Reporter Xu Wei Wei

After the first device in Wuhan Biying was launched at the end of 2020, the overall solution has entered 150 clinical hospitals and printed a total of 1 million examples. According to reports, with the opening of the market, consumers' cost of choosing 3D printing branches will quickly tie the traditional gypsum branches.

【Edit: Ding】

For more exciting content, please download the "Da Wuhan" client in the major application markets.

- END -

Come and participate!Love is long -the most beautiful love story collection and display event began!

There are thousands of emotions in the world. What is your love in your heart?Augu...

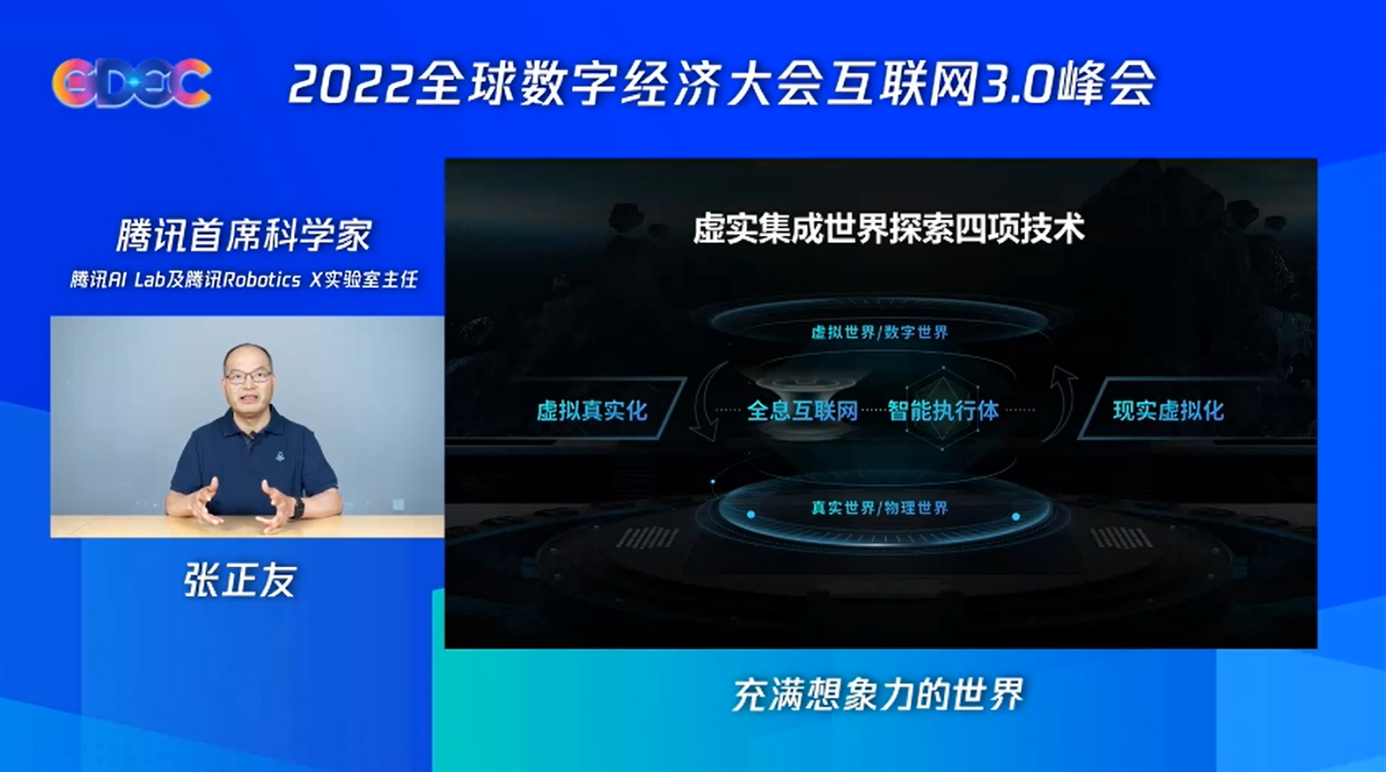

"Number" says the future!Tencent brought the latest technology to the Global Digital Economic Conference

The digital economy is increasingly becoming a new engine to drive economic growth...