The first domestic scientific research team in Sichuan University took the lead in entering the stage of natural gas preparation of green hydrogen hydrogen industrialization

Author:Chengdu Daily Jinguan Time:2022.08.02

Hydrogen energy, as a high -value, high energy density, and diverse source of green energy, is known as the "ultimate energy" of the 21st century.

According to the forecast of the China Hydrogen Energy Alliance of the authoritative agency, by 2030, the annual demand for hydrogen in my country will reach 37.15 million tons. The hydrogen energy industry will become an important part of my country's new economic growth point and new energy strategy. Essence

At present, Chengdu Hydrogen Energy has formed a complete industrial chain of "Preparation-Storage-Transportation-Injecting-Application", which has accumulated 370 hydrogen fuel cell vehicles and promoted the establishment of 2 stations for hydrogenation stations, 1500 kg of hydrogen refreshing/ sky. How to develop lower -cost hydrogen energy and help implement a strong chain of industrial construction circles?

Recently, the reporter learned from Sichuan University that the team of Professor of Sichuan University Professor Fujun on the basis of its first domestic liquid metal hydrogen -making equipment developed on it, on the preparation of molten catalyst materials, reactive furnace design and processing, online continuous carbon excretion technology, etc. A major breakthrough has been achieved, and the stage of molten hydrogenation industrialization has been successfully entered.

Low cost, carbon dioxide emissions

Molten medium cracking hydrogen -making industrialization equipment in Rong successfully developed

At present, the use of renewable energy+hydrolysis solutions are the only technical routes for large -scale production of green hydrogen. , Long -distance storage and transportation safety and other issues. Therefore, the world is currently actively exploring new technologies of green hydrogen hydrogen hydrogen hydrogen hydrogen hydrogen hydrogen hydrogen hydrogen in low -carbon emissions, low -cost, and large -scale applications.

At the beginning of last year, the team of Professor Junfujun developed a liquid metal armal cracking device in China for the first time in China. It uses liquid metal to generate a steady -state thermal solution temperature field. Combined with the catalytic characteristics of the liquid metal itself, it can promote methane molecules to form hydrogen and solid carbon and achieve realization. Zero emissions and efficient hydrogen.

Recently, the team has ushered in new progress -after a year and a half, the new generation of green hydrogen hydrogen preparation technology -the melting medium catalyzed thermal cracks and hydrogen.

"The main ingredient of natural gas is methane. At present, there are a lot of carbon emissions in natural gas reconstruction hydrogenation technology." Fugujun said that the use of melting medium to catalyze thermal cracked hydrogen control technology can unlock the methane in natural gas into hydrogen and solid carbon (charcoal Black, graphite or graphene), without carbon dioxide emissions, can directly use the existing natural gas and LNG infrastructure to prepare green hydrogen.

"The basic principle of melting medium thermal cracking technology is the melting medium material with catalytic characteristics. It is mainly liquid metal and melting salt. As a high -temperature medium, the hydrogen bonds in the hydrocarbon compounds are broken to form hydrogen and solid carbon. No reaction process is Carbon dioxide is generated. "The rich is further explained. At the same time, compared with electrolyte hydrogen, the energy required for catalytic thermal cracks is lower, and it can obtain by -product carbon and higher economic benefits.

In addition, my country's natural gas infrastructure is perfect, technical and unable to restrict regional restrictions. Compared with electrolytic water preparation-storage-transportation-use industrial processes, catalytic thermal cracking technology only needs to transport natural gas through pipelines and produces hydrogen in the user area. The cost of storage and transportation is lower and safe, and it can meet the large -scale application of green hydrogen in the fields of transportation, power, chemical industry, and construction.

The conversion rate is as high as 95%

It can also achieve the production of large -scale graphene

"Through a large number of research and exploration in the past ten years, the team has mastered key technologies such as catalyst material preparation, reactor material selection, structural design and manufacturing, etc., and has independently developed a molten medium hydrogen -making experimental platform." Low -cost catalysts have a methane conversion rate of 95%at 1100 ° C. At the same time, new online carbon removal technology has been developed to achieve continuous hydrogen -making. Related technologies have made major breakthroughs.

In addition, by regulating key parameters such as react temperature, natural gas flow, and catalyst types in the reactor, the production of large -scale graphene can also be achieved, which greatly increases the economic added value of the carbon carbon.

Hydrogen -making cost 18 yuan/kg

It is estimated that the Nissan is 100-500 kg of green hydrogen in 2024

"The estimation shows that the cost of hydrogen system is 18 yuan/kg. With the large -scale application, the cost of hydrogen production will continue to decrease." Fugujun said that the research team has established a research and development platform for key technologies in the Chinese trial. Nissan's test target of 100-500 kg hydrogen. "After the test is completed, we can provide two technical solutions for different application scenarios, that is, centralized large -scale hydrogen -making stations and distributed on -site hydrogen -making stations."

Professor of Fujun has long focused on the foundation and application research of high temperature liquid metals. This scientific research team is very young, and the average age of more than ten members of the first line of scientific research is only over 30 years old. With the support of national research and development plans and the National Natural Science Foundation of China, we have accumulated research experience in application fields such as hydrogen metal hydrogen, energy storage, polymerization filters, boron neutron capture treatment (BNCT) targets. More than 20 patents have been applied for liquid metal hydrogen and graphene, and some results have won the first prize of scientific and technological progress in Sichuan Province in 2019.

"Sichuan and Chongqing's natural gas and rock gas resources are very abundant, which is a good opportunity to develop hydrogen energy." Professor Xi said.In order to achieve carbon peak carbon and carbon neutral and this tough battle, the melting medium cracking hydrogen can become the most potential technical solution to prepare green hydrogen hydrogen hydrogen hydrogen hydrogen hydrogen hydrogen hydrogen to help carbon emission reduction and optimize clean energy structure.The development of this technology is conducive to improving the energy structure of the two places and promoting the green conversion of natural gas.Chengdu Daily Jinguan News Reporter Song Yanyan Editor He Qixie Intern Editor Lu Yarui

- END -

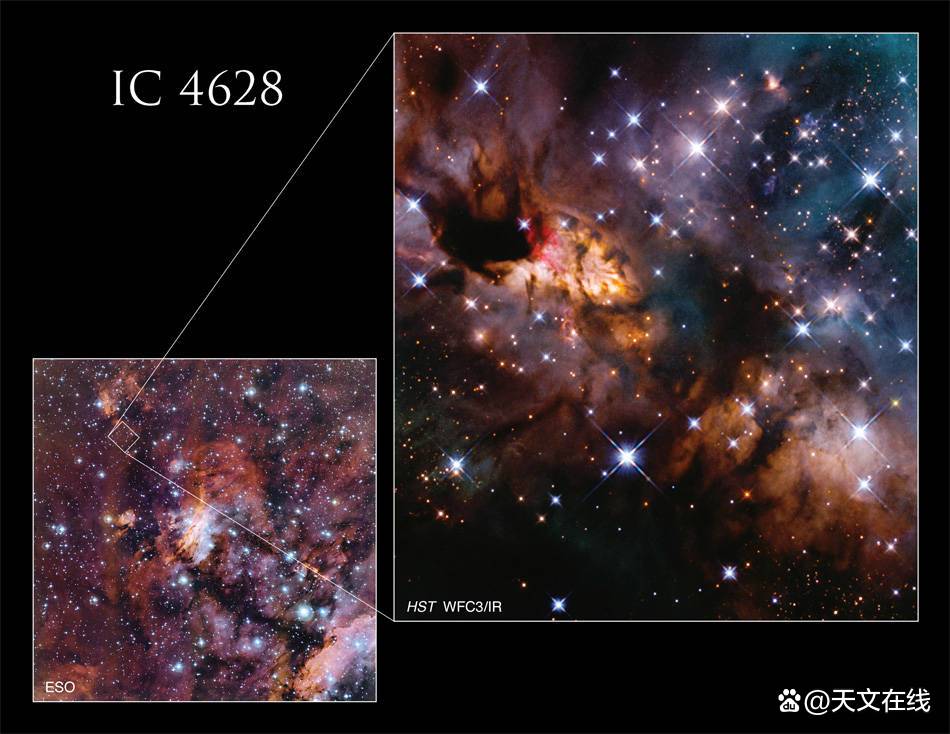

What amazing appearance of the stars formed by the stars?Let's find out

Hubble Telescope captures the surprising image when the star is formed to form a s...

Recognize!Apple abandon iPhone 14 price increase plan

If the endless small fresh meat is the top of the entertainment industry, then the...