Sichuan power behind "Ask the Sky" ① 丨 They create a "air purifier" for the "Ask Sky" experimental cabin

Author:Chuanguan News Time:2022.07.24

Liu Taochuan Guan News reporter Xu Lisha

At 14:22 on July 24, 2022, Wenchang Aerospace launched in Hainan, Blazing Flying, Vocal Everbright, Long March 5 Yao Three Load Rockets Lift Space Station asked the experimental cabin to fly the sky. As the first experimental cabin of the China Space Station, after asking the "place" of the Tiantian experimental cabin, it will provide a good environment for spacemen to carry out space experiments.

The "floating" space station provides a safe residence for astronauts who do experiments in space. It not only has oxygen -making equipment, but also is equipped with a "air purifier" to eliminate carbon dioxide and ammonia gas generated by Navigator activities. , Harm gas such as nitric oxide, ensuring a good gas environment in the cabin.

Sichuan Aerospace Beacon Services Control Technology Co., Ltd., which belongs to the Seventh Hospital of China Aerospace Technology Group Co., Ltd. , In the core cabin and "Ask Sky" experimental compartment of the Tiangong Space Station, used to purify the gas environment in the cabin, which is an indispensable guarantee condition for the safety of the lives of astronauts.

In April 2015, Zhang Jinde, the company's special valve business department, and his team received notifications from the two subsystem assembly and debugging tasks of the space station. "When we first received this task, our entire team was very confused. Because there was no production experience of such products, I didn't know how to start with the design drawings." Zhang Jinde said.

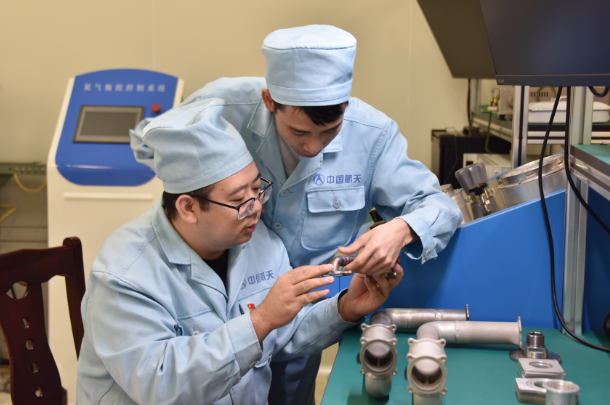

The special valve business department is equipped with Zhang Jinde (right), Hu Buyun (left) is undergoing a tube leak detection test

Since the project is launched, as soon as he goes to work every day, he stares at the only first -like drawing, and he has slowly pondered himself. After half a month of evil, the first operating procedure was finally formulated. At the same time, he proposed more than 30 design and production tools, which saved a lot of time for subsequent assembly and debugging.

Employees of the Diegers of the Special Valve Inspection Department are processing a certain part

The structure of the two subsystems is very compact, including a large amount of complicated and complicated thin -walled pipelines. The structure of the pipelines is compact and irregular. When the pipeline structure is optimized, it is necessary to take into account the actual processing and manufacturing error of the parts and the error of the assembly process. Essence At the same time, the tube parts are installed with large span, and the threaded holes are installed in multiple planes. The size chain constitutes complicated, which causes the accumulation error after the operation, processing, and welding operations is large, and the installation cannot be effectively guaranteed.

"Most of the gas catheter in the product uses metal hard pipes when designing. The installation of each more pipeline will continue to reduce the operating space, bringing great difficulty to the assembly work, and it is difficult to ensure the quality of assembly." Zhang Jinde said.

Company employees are welding the pipelines of the two subsystems

The task team adopts the use of the "size chain accumulation error pre -compensation technology" and does not destroy the original management layout and performance, and the local tube is used to replace the straight tube. In order to meet the requirements of the space station, they almost found all the materials on the market and studied it again. Finally, they selected a ripple tube with a certain flexible characteristics for replacement and verification. This improvement measure is finally recognized by the bending life test and more than a million high -pressure gas gas tight test verification.

At the same time, through the DCC size chain simulation system platform, the error calculation of the size of the entire pipeline installation hole is calculated in advance, maximizing the optimization of the air tolerance, so that the complex pipeline of the entire machine can be installed quickly and quickly.

Zhang Jinde, the special valve business department, is inspecting the two subsystems preparing to deliver

Under the premise of ensuring safety, the task team uses real -time safety weight loss virtual verification technology to conduct a full -dimensional model of the two subsystems through its own multi -physical field coupling virtual verification platform to increase performance, safety, weight reduction, easy maintenance, easy maintenance, easy maintenance, easy maintenance In order to optimize the principle, the whole machine is optimized, reducing the weight of the two subsystems, and reducing the processing cost of the development of the prototype. This development task overcomes a number of technical bottlenecks and breaks through 11 technologies, including 4 core technologies.

In addition, the company also produced hundreds of direct components and components for the Long March 5 Yao Three Laureate Rockets servo institutions. The servo institution is part of the rocket control system. Together with the rocket engine, it constitutes a thrust vector control system at all levels. Simply put, the servo institution is like the "steering wheel" of the Rockets. It is the execution element of the rocket gesture control. It follows the electronic instruction movement, controls the swing engine motion, and controls the rocket's attitude, so that the rocket is flying according to the scheduled track.

It is understood that as an aerospace company involved in the important construction tasks of the space station, the company has participated in the completion of major special tasks such as human science and technology such as manned aerospace and Beidou navigation, and a number of major aerospace engineering tasks such as deep space detection, and a new generation of carrier rockets.

Interviewee confidence

- END -

Academician Li Qianmu: From "manufacturing" to "intelligent manufacturing", Hunan has a lot of promotion

(Li Qianmu. Hunan Daily All -Media reporter Yi Ang)Hunan Daily All -Media Reporter...

The most beautiful science and technology worker | Xiong Hanwu: 60 hours to create a Chinese miracle

Editor's note: In order to interpret the spirit of the majority of science and tec...