State building construction shows wisdom

Author:Legal person magazine Time:2022.07.22

◎ Text "Fighter" magazine all media reporter Li Liao

In the entire high -speed rail construction project, the station building is a beautiful window, testing the strength of the construction party, and directly affects the image and effect of the project. Unlike the traditional construction operations that people usually impressed, the construction of high -speed railway station projects has carried out in -depth exploration in digitalization, informatization and intelligence, and effectively solved many aspects of construction site management, personnel safety, quality control, and construction organizations. problem.

In early July, after a heavy rain in Beijing, Qu Tianliang, a chief engineer of the Beijing Urban Sub -center Station of China Railway Construction Group, is on the construction site to check the construction site's various early warning and monitoring systems on the construction site.

At the rainy season of the rainy season, the settlement and displacement monitoring of the deep foundation pit slope next to the Jinghatie Route Line are important tasks, which is related to the construction of the project. "Previously, after heavy rain, we would arrange personnel to inspect and monitor on -site, but artificial data collection is often not timely, and there are errors." Qu Tianliang told the "Legal person" reporter, "For this reason, the project has developed the slope of the deep large foundation pit slope. The remote real -time monitoring and early warning system, my mobile phone can receive the warning reminder as soon as possible. "

Single city integration breaks the old example of the railway splitting city

The comprehensive transportation hub project of the Beijing Urban Sideline Station where Qu Tianliang is located belongs to the station building project. China Railway Construction Group is the lead unit of the construction unit of the 01 section of the project.

The comprehensive transportation hub project of the Beijing Urban Deputy Central Center is located in Tancheng Town, Tongzhou District, Beijing. Since its opening in 2020, it will become the largest underground comprehensive transportation hub in Asia after completion. In addition, it is the only comprehensive transportation hub to connect the two major airports of Beijing -Capital International Airport and Daxing International Airport. It is also the only transfer hub connecting the Beijing -Tianjin -Hebei and the city center area of Beijing. An important node of the intercity railway and intercity railway liaison line.

The project integrates two intercity railways, a suburban railway, 4 rail transits, one canal terminal and 15 buses. Qu Tianliang said: "After the project is completed, it can achieve one hour directly to Xiong'an New District, Tianjin, Tangshan and other places. 35 minutes directly to Beijing Daxing International Airport, and reach Beijing Capital International Airport in 15 minutes."

The project is 1.9 kilometers long, and the maximum width of the north and south is 192 meters. The reporter stood on the top of the project headquarters building. The vision and the farthest place were the end of the project. The scale was amazing.

▲ Scientific research staff is collecting monitoring data pictures of foundation pits slope

On the construction site, hundreds of operators, dozens of rotary digging rigs, cranes and other large machinery and equipment shuttled through, the Heat was in the sky. But the construction site started for two years, and there was almost no significant change from the surface. Qu Tianliang said that some people living around asked: How did I see what was built for two years. In this regard, he explained that the highlights are underground: "This is an all -underground structure project, with a total underground construction area of about 1.28 million square meters, about 1.39 million square meters on the ground, and the structure of the core area of the hub is 3 floors underground."

The project broke the old example of railway split cities. Based on the concept of "station city integration", the hub station was hidden in the ground, and the organic integration of intercity railways, rail transit, bus yard stations and urban functions was realized.

Smart construction escort Beijing City Deputy Middle Station

The construction of the project is generally from bottom to top, first pouring rafts and then layer by layer, and this project adopts a more difficult anti -work process. "Give up the construction of the top board, pour a lid, and then excavate it down layer by layer." Qu Tianliang introduced that because the project needs to occupy the main road of Beijing East Sixth Ring Road, the existing East Sixth Ring Road needs to guide the existing East Sixth Ring Road during the construction and construction. In addition, there is also a thermal tube and an ultra -high -voltage gas pipeline. "After pouring out the top board, it is conducive to promoting the guidance and reform project as soon as possible. After the comprehensive completion of the steel pipe column construction, it will also reduce unconventional lifting operations such as ultra -long and overweight, which greatly reduces the hidden danger of project safety risks."

The diameter of the inverse steel pipe column is up to 1.6 meters and the length is nearly 40 meters. The construction of the high degree of vertical and accuracy is unprecedented. "In the design requirements, the positioning of the positioning axis is not more than 1 mm, and the vertical deviation of the verticality of the positive steel column is not greater than 1/1000. The pillar single -piece hanging is the most heavier of 90 tons. The construction process involves unconventional lifting operations such as ultra -long and overweight. The overall coordination of safety, quality, and environmental protection has brought great challenges to the construction. To this end, the project department set up a scientific research project group to independently develop the integrated construction vertical visual monitoring system of the pile column integrated construction to achieve visual and real -time monitoring of the installation of steel pipe columns. After the steel pipe column is lifted, the coordinates, inclination, frequency, and amplitude amplitude of each node are collected through the vertical sensor to collect information, and real -time school nuclear verification is performed during the plot under the steel tube column to ensure the best construction accuracy.

In the pile foundation construction, the height accuracy control of the concrete liquid surface of the concrete pile roof is the key process. "According to the requirements of the counter -work method, the length of the large diameter concrete irrigation pile is 27 meters. Such a deep pile foundation concrete top label high (refers to the elevation of the pile roof after breaking the pile head. . The height indicates that the height of each part of the building is a vertical height of a certain part of the building relative to the benchmark surface and is the basis for vertical positioning.) It is very difficult to control. Whether the previous project meets the standards. Methods are easy to cause errors. "Qu Tianliang said." The project research team independently developed the magnetic detection device of steel concrete pile piles in the project. It uses ultrasonic, pressure, conductivity, density and other sensor technologies to achieve controlling the height of concrete irrigation. "

The average depth of the foundation pit of this project is 32 meters, which is a super underground space structural project with complex geological conditions and the construction environment. "Because the northern canal and the tide reduction river reduction, it belongs to the ultra -high pressure -rich water formation. At the same time, the north side of the Kenkeng is adjacent to the Jingha Railway. It must be ensured that the construction is safe and reliable." Qu Tianliang told reporters that in order to separate the water, the project adopted 50 in -depth underground 50 The uninterrupted underground walls of the Duomi water layer reduce the impact on the surrounding environment and the waste of resources caused by pumping water.

In order to fight groundwater buoyancy, the 1278 anti -piles currently under construction are one of the many measures to solve structural anti -floating. It is said that the project department will also intelligently monitor the groundwater level and the surrounding leaks to control the level of groundwater level.

The reporter came to the project department's office with Qu Tianliang. The supervisor of the project headquarters was looking at the progress of the project from the computer's intelligent monitoring module. The screening screen showed a selected worker walking trajectory. "For large -scale mechanical equipment and personnel, we can all provide all -round supervision and give timely reminders to construction personnel who lack security awareness." The regulators said that "the initial stage of project construction, the new generation of wisdom construction work is based on BIM -based BIM , Three -dimensional GIS, the Internet of Things and other new technologies, build a model of engineering digital construction, and create a smart construction platform covering the entire life cycle of the project. "

The reporter saw through the project renderings that the station building is different from the traditional all -underground railway station waiting hall, and the sun is introduced into all floors of the underground. The location of the two -story floor of the east of the waiting hall adopts a large -scale lighting well with a length of about 93 meters and a width of about 85 meters. The sunlight is directly introduced to the ground.

Qu Tianliang introduced that during the construction stage of the inverse structure, a series of scientific research activities and scientific and technological research will be carried out, and BIM modeling technology will be used to make full use of BIM modeling technology, multi -professional collaborative optimization, and provide strong scientific and technological support for the high -quality construction of the sub -center station.

Fuxia online wisdom reproduction

The existing Xiamen North Station is located in Jimei District, Xiamen City, Fujian Province. It is the first large -scale station building undertaken by China Railway Construction. It has been welcomed to passengers for more than 10 years since it was opened to traffic in 2010. On June 15, 2021, China Railway Construction Group successfully won the new Xiamen North Station project and returned to the place where it was once "fighting."

New Xiamen North Station is an important transportation hub to build a "one -hour economic circle" on the southeast coast. On July 4, the project commander Li Yanchang told reporters that after the project was completed, the number of passenger sent by the site will be 2.8 times the current year. At the same time, the time from Xiamen to Fuzhou will be shortened to 50 minutes. The development of the Haixi urban agglomeration is of great significance.

Today, the construction team that has just been settled in the project has overcome many difficulties such as pile bases and subway protection. "Now is the era of intelligence. Digital intelligence has become an irreversible trend in the construction industry. It is very different from the construction of Xiamen North Station a decade ago." Li Yanchang said.

In the main stage, the project chief engineer Zhao Zhongcheng has long been "unable to hold back" the idea of building a smart construction site. He led the five major modules: smart processing, smart monitoring, smart construction, smart epidemic prevention, and smart management, so that construction production was improved.

The project team has established CNC steel processing centers, introducing high -tech control equipment, and realizing intelligent and mechanized steel processing. Six production lines and 20 workers can process 180 tons a day, the stirrup can complete 60 tons per day, and 120 tons can be completed with silk and stick bending anchors. Compared with the previous pure human work operations, the processing efficiency of 1: 1.8 was achieved, and the product qualification rate reached more than 98%.

In order to monitor the number of rolls, loads, rotations, and cross -distance runnings of the wind speed and 11 tower cranes, the project team established a group tower monitoring system to accurately early warning collision, over -limit, dumping and other dangers. The AI inspection robot is 360 -degree turning the panoramic inspection construction site. It can "do the net" every corner of the 150,000 square meter venue. The project team also uses 10 intelligent robots, including face -to -face robots, Zhenping robots, and welding robots to replace artificial artificially, introduce "mechanical commanders", monitor the operating rate, usage rate and activity trajectory of each construction machinery throughout the process, and discover idle time in time Machinery, improve mechanical utilization.

Nowadays, as many as 40 wisdom applications have blossomed in the new Xiamen North Station project, and Zhao Zhongcheng often forgets that he has forgotten the day and night. He is already full of gray hair. When the project fully entered the steel structure construction, he again thought about how to embed more smart applications in more complicated steel structure construction.

Editing | Cui Xiaolin

Edit | Bai Kui

School pair | Zhang Bo Zhang Xuehui

This article is published in the "Legal person" magazine in July 2022 The total 221 cover story column

- END -

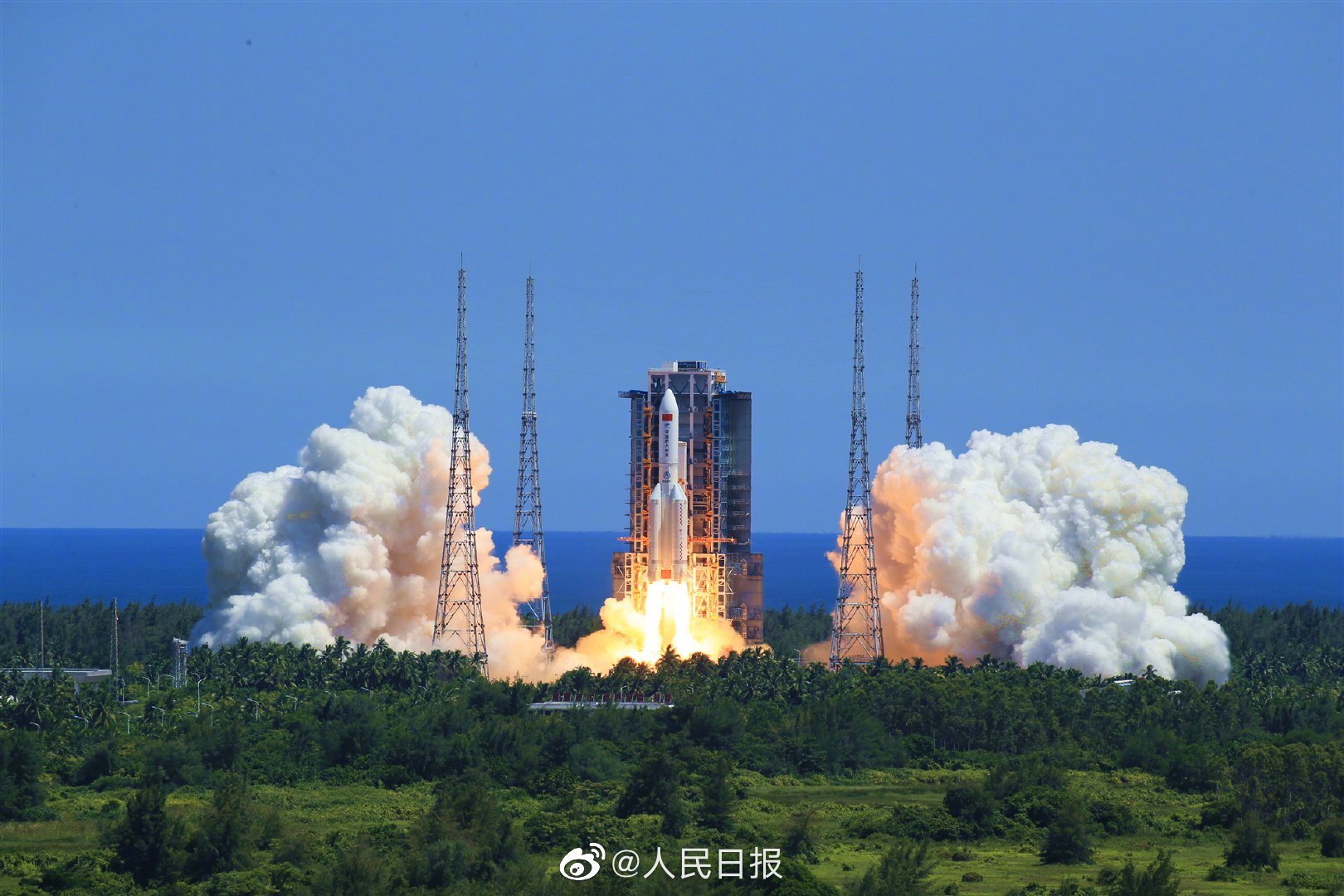

Asked the launching task of the sky, the launching task was successful, and the moment of the angle of view was asked about the moment of the sky lift

Poke the video ↑↑↑ Multi -perspective to see the launch of the Tianjin exper...

What?We still live in the dinosaur era!

To say that the most popular exhibits in the Natural Museum, dinosaurs are definit...