Zhang Hui: Carve the silicon electrode parts into "Daqian World" 丨 Struggler is youth

Author:China Science and Technology A Time:2022.06.15

Science and Technology Daily Intern reporter Sun Mingyuan

The outline of the parts outlines a yellow ring on the computer screen, which is evenly distributed in the ring with hundreds of green dots representing small holes. Essence Zhang Hui in front of the screen carefully screens each parameter, and the "derailment" of any particles in the parts may cause the "collapse" of the entire structure in the semiconductor production process.

Zhang Hui is the general manager of Beijing Yisheng Precision Semiconductor Corporation. Since coming to this company in 2018, one of the main challenges she faces is to carve this small pore -shaped silicon electrode part. During the production of semiconductors, etching gas such as carbon fluoride entered the production cavity through small holes on the silicon electrode and occurred on the wafer. This process has high requirements for the smoothness and cleanliness of silicon electrodes. For a long time, China does not have the ability to produce qualified silicon electrodes, and can only rely on imported products.

Drawing: Yangmei Interactive

After graduating from school in 2010, Zhang Hui entered a microelectronics equipment manufacturing company. In the 8 -year work experience, Zhang Hui had a deep understanding of the problem of "stuck neck" of the parts. Semiconductor production is an extremely complicated process that involves thousands of various components. Some of these parts are durable products and some are consumables. Among them, silicon electrode parts are consumables, but the technical content of this "consumable" is very high, and at the same time, it plays an indispensable key role. Zhang Hui sometimes compares the semiconductor production line to a printer, that is, if only the machine is the whole, but there is no consumables such as toner cartridge and ink cartridge, the printer cannot be used. Therefore, only by polishing each seemingly inconspicuous part to the extreme can the entire production line run smoothly.

With such cognition and ambitions, Zhang Hui joined Beijing Yisheng in 2018 and is responsible for supervising the major national science and technology projects undertaken by the company as a whole. The project content is the research and development and industrialization of key components. After nine months, Zhang Hui and his team finally developed a qualified silicon electrode. The research and development of silicon electrode principles has overcome the problems of two links. First of all, how to punch, and then how to ensure its stability and cleanliness. These two problems are solved by thousands of physical and chemical experiments behind them. After the success of the principle, industrialization has become a new challenge. To this end, Zhang Hui obtained feedback from the cooperative enterprise and continued to improve silicon electrode parts in the experiment.

"We have developed parts and consumables, but the" gold content "of this work is not low. There are too many technical fields involved in integrated circuit production, and no one or a company can master it. Each process is very important. Any details can cause the entire chain to be unable to connect. "Zhang Hui concluded.

"We also hope that more young talents will join the semiconductor industry and join in physical manufacturing." Although the parts are small, it contains the entire world, and there is a vast world inside and outside the microscope. Looking back on the road that has been gone, looking at the future, Zhang Hui said that such youth is worth it.

Source: Science and Technology Daily

- END -

Hangzhou University Student develops an intelligent robotic robot to cultivate children's growt

On June 8th, a children's education institution in Hangzhou ushered in a special g...

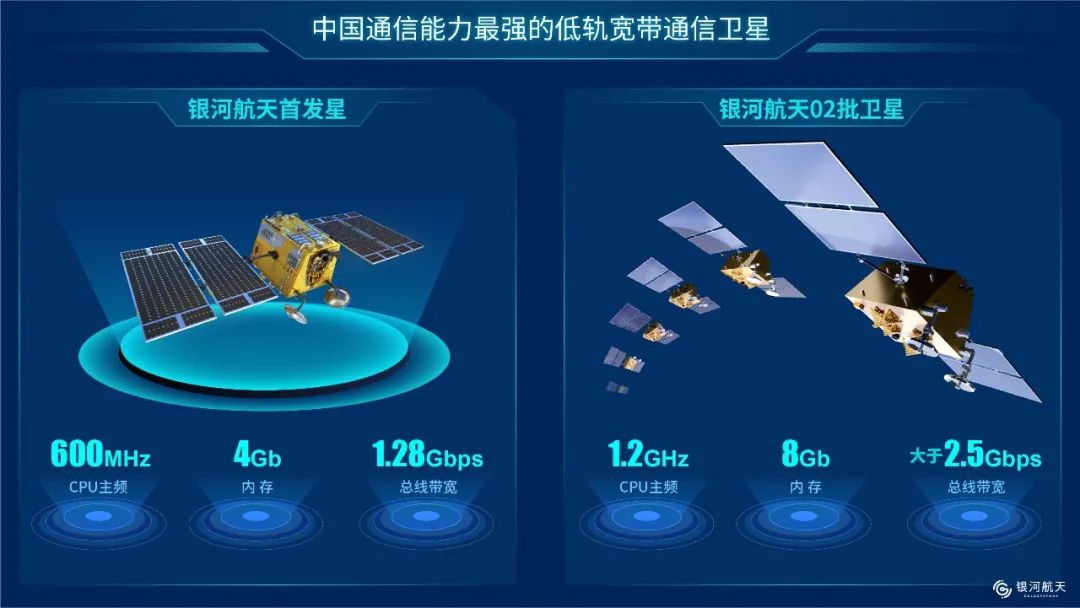

When the satellite opens computer

As an entrepreneur in the field of satellite, I deeply feel that in the past two y...