Xinjiang Silicon Resistance Material Company: Add bricks to the construction of beautiful towns

Author:Tianshan.com Time:2022.07.07

On May 22, the employees of Xinjiang Silicon Resistance Co., Ltd. worked on the brick production line. Pomegranate cloud/Xinjiang Daily reporter Xie Long Photo

Tianshan reporter Wang Yongfei

In the steaming factory building, a piece of long square brick walks on the production line, such as the queue soldiers are neat. "Don't underestimate this production line, this is a technological innovation of handmade production technology that inherited the green brick inherited in 2000, and realized the mass, automated, and customized production of green bricks. Production line. "On June 28, Gao Jianmin, chairman of Xinjiang Silicon Resistance Co., Ltd., proudly said.

On the open space next to the production line, the blue brick code is neatly placed, how tall is one. Gao Jianmin introduced that this green brick has high strength, good cold resistance, good breathability, and not losing color. It is a good material for laying urban squares and pedestrian trails. Especially the surface non -slip effect is very good, especially suitable for the northern market. "Sending the product on the Internet, other provinces have expressed amazing. Can Xinjiang also produce such products?"

The production of antique trail green bricks is one of the results of the innovation concept of silicon refractory material company to improve the process process. In addition to the production of antique tract green bricks, the transformed production lines can also produce sintering bricks such as building decorative bricks, high -intensity tiles, solid waste steel residue bricks, and ceramics, porcelain, etc., which has opened up a broader development prospect for enterprises.

On May 22, the employees of Xinjiang Silicon Resistance Co., Ltd. worked on the brick production line. Pomegranate cloud/Xinjiang Daily reporter Xie Long Photo

The determination to transform the craftsmanship must be said from three years ago. Relying on the only refractory clay mine in the whole Xinjiang mine, the company has a history of nearly 20 years. However, there are many types of refractory materials, small markets, and large competition, and it is difficult for enterprises to achieve breakthroughs in the market. Compared with cement bricks, sintering bricks are good, pollution -free, and large in the market. Using a large number of tailings can also form a core competitiveness of the enterprise.

After research and market inspection by the board of directors, the company decided to carry out technical reforms. Since the transformation of the production line in the spring of 2018, the company has done all the funds and basically completed the production line technology transformation in June 2020.

However, starting the production line, at least 5 million yuan of liquidity is needed. At this time, the company is already full of mountains and rivers. Where does the funds come from? Gao Jianmin raised funds everywhere and repeatedly touched the wall. "It's just like this, what can I do?" In addition, the company was facing the pressure of the epidemic. "The epidemic caused the suspension of production, and the losses caused more than 10 million yuan, which was very stressed." Gao Jianmin said.

"Since it is so difficult, why should we promote technical reform?" The reporter asked Gao Jianmin.

"The technical reform will experience the pain; if you do not change it, you will be eliminated by the market like warm water. Was it waiting for death or Nirvana rebirth? This is not difficult to make a choice."

Fortunately, the State and Autonomous Regions have issued a series of policies to help enterprises' rescue policies, allowing enterprises to usher in a turnaround. At a bank -enterprise docking meeting in September 2020, after understanding the situation of the enterprise, the Industrial Bank Urumqi Branch learned that the company was optimistic about the company's development prospects. The charcoal in the snow gave the company a 6 million mobile fund loan, and the production line was finally launched!

In addition to enjoying the financial assistance policy, the silicon refractory material company also enjoyed the VAT tax refund policy, which has injecting the power of the company's transformation and development. Looking forward to the future, Gao Jianmin is full of confidence: "The demand for the sintering brick market is 10 billion yuan in Xinjiang, radiating to Central Asia, which will be a 100 billion yuan market. It is expected that our output value can reach 200 million yuan this year."

While realizing the use of tailings and sintering bricks, the silicon refractory material company is promoting the construction of the Green Building Materials Industrial Park of the Grand Solid Waste Circular Economy. "By then, we will use industrial fixed waste and construction waste to produce sinter bricks to build bricks to build non -waste cities." Gao Jianmin said.

In Gao Jianmin's view, the company uses tailings, industrial solid waste, and construction waste processing bricks, which is turning waste into treasure. "The sintering bricks we produce are non -pollution, not only eliminating the original garbage of the city, but not only new pollution. We are in the next plate of solid waste circulating economy green building materials industry. Radiation to Central Asia and Europe. "

- END -

The year -on -year increase of 1.2 times, and the scale of new energy vehicles in the first half of the year reached a new high

Xinhua News Agency, Beijing, July 19 (Reporter Zhang Xinxin) Tian Yulong, chief en...

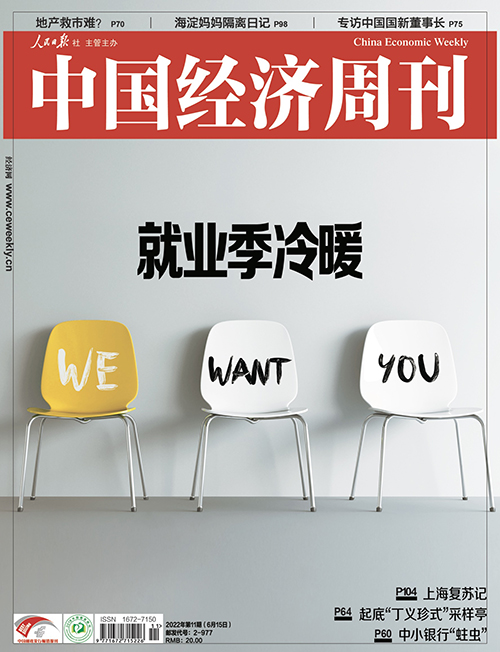

Cold and warm in employment season

The cover of the 11th issue of China Economic Weekly in 2022China Economic Weekly ...