"Intelligent Manufacturing China" in -depth decoding China Feihe "Intelligent Manufacturing" internal skills

Author:Economic Observer Time:2022.09.26

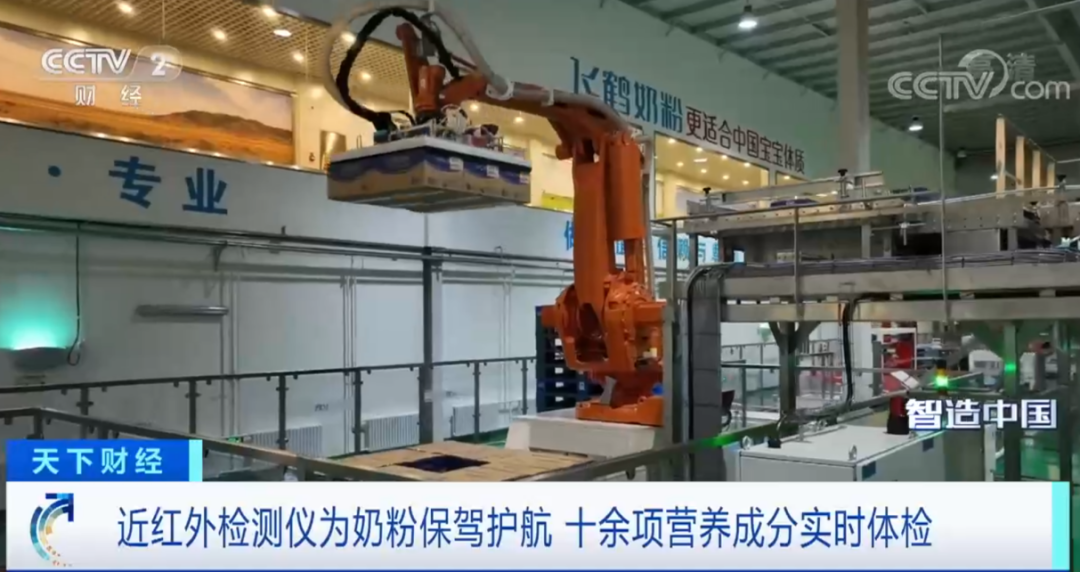

The densely arranged equipment is constantly running the roar of operation. Several tons of fresh milk flows in the pipeline. The yield value of milk powder on the display is continued to rise, but the large workshop is not seen ... These are all Chinese infants under the CCTV lens. Leading Enterprise -Feihe production workshop scene. Recently, the large -scale melting media jointly created by the Central Radio and Television Terminal and the Ministry of Industry and Information Technology reported that "Intelligent Manufacturing China" walked into the Feihe Smart Factory, decoded a new height of Chinese milk powder intelligent manufacturing, and explored how to produce fresh milk powder for Chinese babies. This is also the end of the "Intelligent Manufacturing China" series.

Full detail

Precisely controlled the "smart" brigade of the escort milk powder

The lens of "Intelligent Manufacturing China" swept through the intelligent sterile workshop of Feihe. Each frame was interpreting the intelligent style of the Chinese dairy industry in the 4.0 era of the Industry 4.0, and it talked about the changes brought about by intelligent manufacturing for the food production industry.

Milk powder is the most complicated production process and has high requirements for processing technology. There are more than a dozen processes in the production process. Each step needs to be under strict quality control. Intelligent manufacturing makes this control more accurate and steadily supports it steadily. Each can of high -quality journey of milk powder.

In the lens of "Intellectual Manufacturing China", the entire production workshop of the Flying Crane Factory cannot see a drop of milk or a milk powder, and all raw materials are staggered in stainless steel pipes and bottles and cans. The report mentioned that during the manufacturing process, the raw milk will scientifically match and mix with the nutritional elements required by more than 30 infants and young children. The types and dosage of different formulas are different. This requires very fine quality control capabilities to ensure that scientific formulas can achieve accurate matching. For the amount of milk powder calculated, the raw material calibration system of Feihe can control the error within the range of 0.1 grams.

In the process of milk powder, temperature control is also very important. It is necessary to complete processes such as evaporation, dryness and sterilization, but also retain active nutritional ingredients. Intelligent manufacturing achieves precise monitoring of temperature through sensors on the device.

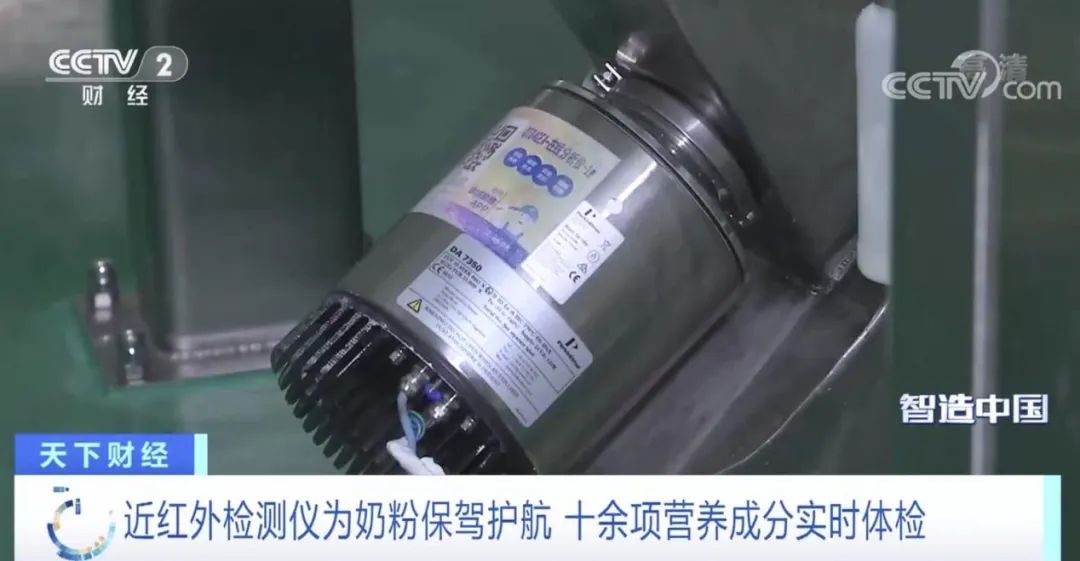

In addition, "Intelligent Manufacturing China" also emphasized in the report that near the powder outlet, Feihe installed online near infrared equipment, and can scan more than 10 indicators in milk powder more than 20 times in one second. The frequency output detection results of 20 to 30 times realize the "second -level monitoring" of milk powder quality. This is also the first application of near -infrared technology in the global dairy industry.

The accurate control of the intelligent system on the dripping link not only guarantees the quality and safety of milk powder, but also guarantees the freshness and activity of milk powder to the greatest extent. Feihe's exploration and practice in intelligent manufacturing also set a benchmark for the industry.

Install the "brain" for the factory

Quality improvement and efficiency and efficiency double -pronged approach

The reason why the manufacturing details are so strictly controlled because the Feihe Factory has a very smart "brain".

It is understood that Feihe began to systematically plan to promote the construction of smart factories as early as 2016. Especially since 2018, Feihe has continued to implement the "3+2+2" digital strategy, and intelligent manufacturing has become one of the important IT projects of "3".

Feihe imports all equipment, personnel and assets into the system, modeling the entire factory, and re -sorting out the process of storage, storage, testing, production, temporary deposits, and outlets of the entire factory. Design the optimal production plan by algorithm. At present, various factories in Feihe have access to four core intelligent systems including production, laboratory, and warehousing to achieve intelligent production.

More importantly, with the development of comprehensive digital upgrades, Feihe continues to promote the construction of digital China -Taiwan, open up data barriers, and continue to improve digital capabilities. It is with the support of the data and Taiwan that the four major systems of smart factories can successfully connect and interact with each other, and achieve close monitoring of the entire production process. In this way, when a certain process parameters have regular fluctuations, the data on the data can be keenly discovered and feedback to the production line in time to guide the cause of production analysis fluctuations. On the whole, intelligent manufacturing allows Feihe to achieve digital management of the production process, and more accurate quality control. In addition, intelligent manufacturing empowerment has also greatly improved production efficiency. Take the Flying Crane Fast Factory as an example. From fresh milk and various raw materials to becoming a box of comprehensive milk powder packaging, each production process is digitized, and the whole process does not exceed 2 hours. The production line that is busy day and night can reach 50,000 tons a year, and the entire process can be completely controlled by several staff members of the central control room.

Global digitalization

Good milk powder starts with technology raising

In addition to the production side, the digital layout of Feihe can be extended to the source of the milk forward, and can reach thousands of consumers backwards. The consumption side has formed a positive feedback cycle, which has brought profound changes to the industry and market.

Good cattle can produce good milk. The ranch is an important part of Feihe's global digitalization. Since 2006, Feihe has rooted 47 ° golden milk sources north latitude, and has built a trinity industrial cluster of agricultural and animal husbandry, including 10 own pastures. Feihe deepen the digital innovation into the pasture, and implement large -scale data raising to ensure the safety and quality of milk sources.

Through the lens of "Intelligent Manufacturing China", you can see that each cattle is equipped with an RFID electronic earmark and chip collar in the flying crane pasture. They jointly constitute the "electronic identification system" of cows, which provides reference for staff to control the condition of cattle in all directions. "Electronic earmark" is equivalent to ID cards, related information, and facilitates inquiries and traceability, such as parental information, immune time, etc. The chip collar is similar to people's smart bracelets, which can monitor health data, such as detecting the amount of feeding and activity, providing reliable analysis materials for scientific feeding.

With the advancement of comprehensive digital upgrades, the digitalization level of Feihe Ranch has continued to rise, significantly improved the efficiency, yield and quality of raw milk milk. With the cooperation of ID cards, collar chips, milk production, and feed to each system, the management of more than 10,000 cows requires only more than 40 people. The yield of each dairy in high -quality ranch has reached 39 kg, which is more than 10 kilograms higher than 10 years. More importantly, the safety and quality of milk are far exceeding Chinese standards, and they also exceed the EU standards that are regarded as the highest standard of international fresh milk. It is understood that Feihe has the standard milk and protein content of fresh milk and protein in the pasture of 3.8%and 3.4%, respectively, and the colonies index index is less than 5000CFU/ml, and body cells ≤150,000/ml.

In the supply chain link, Feihe achieved a small batch and high -speed flexible production by creating a smart supply chain, capturing market demand in a timely manner, accurately predicting market demand through the traceability system, not only accurately meet consumer needs, but also stabilizes the freshness of milk powder. Degree -only 28 days from the filling to the baby bottle that is loaded into the baby.

Digitalization also makes Feihe's services more personalized and temperature. With the help of the digital system, Feihe provides consumers with customized education services through platforms such as Star Mom Club.

From automation, digitalization to intelligence, every step of flying crane innovation is moving towards "fresher products, more professional services, and more accurate needs". CCTV highly affirmed the changes brought about Feihe's dairy industry. "Intelligent manufacturing is making the quality control of the Chinese dairy industry more stringent and more accurate, and it also gives consumers a safer, more nutritious and fresher. milk powder".

In addition to the lens of "Intelligent Manufacturing China", Feihe's digital industrial chain and intelligent production line will continue to guard the healthy growth of Chinese babies and lead the Chinese dairy industry to a higher quality development.

(News)

- END -

How many bank card do you have?Come "one -click check card" →

friends,Do you remember how many bank cards in your name?China UnionPay recently a...

Visit Huiju 丨 Do a good job of "non -heritage" article drives the villagers to become rich

Tianshan.com correspondent Xu Xiufang Feng Lei Xiong YanRecently, in the live broa...