Gongcheng farmers will innovate art, and turn waste into a cedre Chinese chapter

Author:Huaihua People's Broadcasting Time:2022.09.26

(Wang Zhicong) seedling seedling is the first step in the production process of vegetables. It can increase the seedling rate of seeds, promote the precocious and high yield of vegetables, extend the growth season, reduce pests and insect pests, increase planting stubble mouth, and ultimately improve economic benefits. In recent years, my country's vegetable seedling industry has developed rapidly. About 2/3 of vegetables produced all year round have been transplanted with seedlings. The demand for seedling seedling seedlings in the country has exceeded 680 billion yuan, while intensive seedling seedling seedlings are only 200 billion. The gap is the gap. More than 70%.

As the basis of vegetable seedlings, the matrix can replace the soil to provide nutrition for the growth of seedlings, which is the key to the development of vegetable seedlings. At present, the organic substrate of solids exceeds 150 million m³, and its raw material grass charcoal needs to be imported by more than 80%, and the price is high, which seriously restricts the development of my country's vegetable seedling industry. "It is imperative to produce high -quality, low -priced, renewable local seedlings." Said Duan Peicheng, director of the Chemical Engineering Department of Xi'an Jiaotong University.

1). Improve traditional technology and solve the pain point of the base production industry.

Grass charcoal is the most commonly used basic raw material for vegetable seedling matrix. It is the residual body of the swamp plant. Under the condition of hydrophilic gas, it cannot be fully decomposed and piled up. Minerals. Therefore, Cao Carbon is a non -renewable mineral resources. The Wetland Protection Law, which was officially implemented on June 1, 2022, was completely banned from mining carbon in Cao Carbon Marshwan Wetland.

"The natural formation process of simulated grass charcoal is a scientific strategy of cracking problems." Duan Peicheng said that the treatment of biomass through water and thermal reactions is to use artificial synthesis to simulate natural reactions and quickly transform biomass into the resources that people need.

The traditional domestic matrix production method is to use straw and poultry and livestock to mix and ferment directly, and then further reproduce. However, there are two pain points: ① The fibrous protection structure inherent in straw can hinder degradation; ② The protein reaction in the manure will cause odors, insect pests and nutritional loss. "If these two pain points cannot be resolved, it will cause more than 30%of vegetables to reduce production." Duan Peicheng said.

To this end, after years of hard work, Professor Duan Peicao's team has analyzed the technical bottleneck based on the pain points of the industry, and combined with the current vacancy of the seedling matrix market in my country, and proposed the innovative renewable matrix preparation technology process: The raw material is coupled with steam blasting technology with good oxygen fermentation technology to prepare renewable seedlings. The team used new engineering technology to solve the problem of difficulty in the treatment of agricultural solid waste, while changing waste into treasure.

2). Improved the natural response, and use steam blasting coupling to produce oxygen and fermented to produce artificial grass charcoal

"Our matrix production process mainly includes two core technologies: steam blasting technology and good oxygen fermentation technology." Duan Peicheng introduced that steam blasting is the pre -processing process of the raw material, using the explosive power of the steam Good oxygen fermentation completely converts the raw materials into artificial grass charcoal.

In the initial small trial stage, Duan Peicheng team used steam blasting technology to handle straw and poultry stains, but during the subsequent fermentation process, the nutrient would be lost as the fermentation temperature increased. "So we tried to mix straw straw and poultry and livestock, and then perform steam blasting." Duan Peicheng said that the cymbal compounds in straw and amino compounds in the feces collaborate. The loss of nutrients in the next fermentation process can also effectively remove the odor.

Duan Peigao said: "This technology has a very big advantage, which is the short response time. It only takes 10 minutes from adding raw materials to blasting, and the blasting process is less than 0.01 seconds.

Based on the destruction of the raw material fiber structure, oxygen fermentation is used for further treatment of the raw materials. "Fermented bacteria quickly reproduce in the raw materials, combined with ventilation, compost and throwing, can completely rot the materials in a short period of time, degrade the lignin in the raw materials into the most important nutrients in the growth process of plant growth -corruption Colonial acid. "Duan Peicheng introduced.

Compared with Germany, the artificial grass charcoal produced by Duan Peicheng team was reduced by 85%, the fermentation cycle was shortened by 75%, the humusization rate increased by 40%, and the egg destruction rate of insect eggs reached 99.9%.

3). Achievements are transformed on the ground, and the people's living standards are improved with scientific and technological power

The fundamental purpose of scientific research is to apply to improve people's quality of life. "Scientific research should pay attention to the major national needs and keep up with the pace of social development. It is not a matter of doing experiments to post articles, but to transform scientific research results into actual social productivity and contribute to improving people's living standards." Duan Peicheng said.

In 2019, Duan Peicheng's team began research on steam blasting treatment technology; in 2021, cooperation with Xifeng Liquor in Shaanxi Province to study the efficient resource of leisone and use the preparation of high -protein feed technology; in 2021, the team completed the project test in the project. Research work, and based on steam blasting technology, established Shaanxi Qingbei Yako Environmental Technology; in 2022, Qingbei Yako cooperated with Xinjiang Tianwang Environmental Protection to produce seedlings that meet national standards with straw and poultry and livestock manure. The matrix. "During the mid -testing stage, the annual output of our matrix is 700 tons, which can solve the demand for vegetables for 17,000 people for a year." Duan Peicheng said.

Xinjiang is a large agricultural province. A large number of straw and poultry and livestock pollution waste produce each year, and the current reuse of biomass waste resource resourceization is immature and the utilization rate is low.Duan Peigao said: "Our technology plan will be promoted in Xinjiang next year, making full use of local waste resources, and the amount of stains and livestock stains can reach 150,000 tons of annual treatment." "After the production line is completed6.6 million tons can cultivate 1 billion seedlings, which can meet the demand for vegetable supply of 1.6 million people and improve people's living standards. "Duan Peicheng said.

Duan Peica team has launched a demonstration experiment of tomato, melon and gray dates in Xinjiang.After testing by third -party institutions, the product was excellent, and the user's feedback was good after testing.

Duan Peigao said: "Our technology can not only use straw and poultry and livestock feces as raw materials, but also use regional characteristics as raw materials. We have promoted the recycling of the resource of agricultural waste, and it is" 3060 3060 3060"The realization of the double carbon target provides strong technical support."

- END -

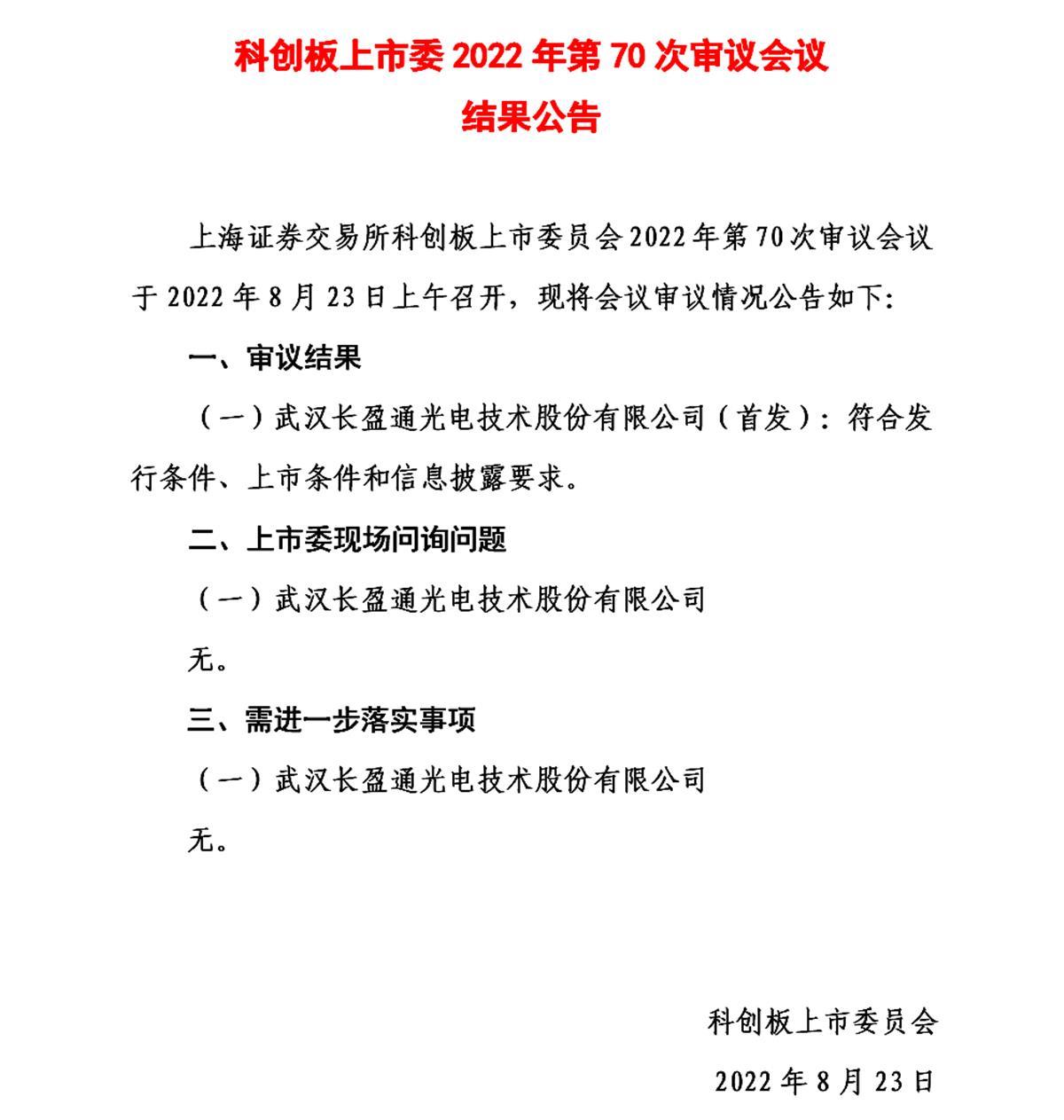

The domestic "Fiber Circle First Share" science and technology innovation board, the 57th listed company of Optics Valley was born

Jimu Journalist Hu ChangxingCorrespondent Kang PengIntern Xiang Ke Yan Wu YuzhengO...

Haimen Third Factory Industrial Park: "Specialty Specialty" has become a distinctive feature of industrial transformation and upgrading

In the hot summer, the Haimen Third Factory Industrial Park has gained scientific ...