Longbai Group chloride titanium white powder intelligent factory: booster to enhance high -end market competitiveness

Author:China Chemical Newspaper Time:2022.09.21

After the chloride titanium white powder intelligent factory was completed and put into operation, the qualification rate of Longbai Group titanium white powder products increased to 99%, and the product performance reached the international standard level, ranking among the forefront of the same industry; compared with the traditional sulfuric acid method White powder technology is more green and environmentally friendly. The amount of waste stacking is reduced by more than 90%, saving energy consumption 30%, saving water consumption 50%, production costs greatly reduced, and environmental benefits and economic benefits are significant. Grasp the dominance of my country's high -end titanium pink powder market, and it is expected to achieve domestic high -end titanium white powder replacement imports ... With many intelligent construction results, the Longbai Group's chloride titanium white powder intelligent factory has successfully selected a typical digital transformation of the China Listed Companies Association. Case.

"Intelligent factory construction is a booster that enhances the company's competitiveness and influence in the international mid -to -high -end titanium pink market." When talking about the meaning of the construction of the chloride titanium pink smart factory Qi Manfu, the general manager of the company, said that through the construction of an intelligent factory, the level of Titanium white powder technology and enterprise management level has been greatly improved. The company's titanium essence — chloride chloride — chloride titanium pink powder — sponge titanium — titanium alloy all industrial chain is optimized and upgraded; greatly improves the quality and production efficiency of titanium pink products, and cultivates a number of intelligent and digital transformation for the company. Talent, significantly enhances industry brand influence and domestic and foreign market competitiveness. At the same time, the chloride titanium white powder intelligent factory has established a model of intelligent manufacturing for the same industry, and has played a role in promoting and demonstrating the development of the industry's intelligent manufacturing.

Build a huge intelligent digital system

Product high -end and enhance market competitiveness

my country is the largest country in the world to produce titanium pink, and the production capacity, output and export volume of titanium pink are ranked first in the world. However, my country's titanium pink industry is currently facing two major problems. The first is the backward process of titanium pink powder. Internationally, the production process of titanium pink powder is mainly chloride, while my country's chloride titanium pink production capacity accounts for less than 10%of total production capacity. Second, my country's titanium pink industry is mostly mainly low -end products, and low -priced competition has become the norm of the industry.

"In order to solve these two major problems, enterprises must accelerate the integration and development of new generation of information technology such as animal Internet of Things, big data, and cloud computing, and pilot the construction of smart factories and digital workshops in key areas." Qi Manfu said.

"According to the characteristics of the titanium pink industry, Longbai Group has established a research and development team to carry out technical research from three aspects: intelligent design, intelligent production and intelligent operations. Through the construction of intelligent factories, Longbai Group logistics, capital flow, and information flow realize comprehensive integration management; Through the data records, summary, and analysis of the entire process of production, inspection, sales, and product delivery, the data -driven intelligent decision -making is achieved by the longitudinal integration, horizontal integration and value chain of data, and improved the technical level, production efficiency and management capabilities. At the same time, it has significantly improved the company's comprehensive competitiveness in the domestic and foreign titanium white powder industry. "The" Typical Cases of Digital Transformation "issued by the China Listed Companies Association made such evaluations of the Longbai Group's chloride titanium pink intelligent factory.

"Behind the chloride titanium pink powder production line is a huge intelligent digital system. Among them, the production units are widely used in data products and test data management systems, and the production line supports corresponding distributed control system (DCS) to achieve automatic production production, all process parameters, all process parameters All can be at a glance on the PC. The operator will timely deploy the system parameters in time according to the indicator fluctuations to achieve real -time scheduling of the production process. "Qi Manfu said," Not only that, we are also installed in core production equipment such as chloride and oxide furnaces and other core production equipment installation smart sensors In real time monitoring, analysis, and early warning of equipment status, effectively avoid non -planned stops caused by the failure of the unit, and can reduce the loss of 15 million yuan per year. At the same time, the production area is equipped The online monitoring system, etc., grasp the production security dynamic information in all -round, whole process, and multiple angles. "

Open the data islands between the cross -system

Realize process optimization and data decision support

"Previously, there were many information systems in the company, and the demand for specific data between different departments could not be met. There were serious data islands between business analysis between cross -system. In addition, the internal operations and business systems of the enterprise accumulated a lot of historical history every day. Data, these massive amounts of data have not been effectively analyzed and used. "Qi Manfu said," Faced with this situation, we use data decision system to establish business management data analysis platforms, and use industrial mechanism models, industrial microservices and other technologies to produce and operate data Make analysis and extraction, realize the real -time collection and summary of poly source data, open up data barriers between various business systems, so as to call data across systems, and provide data support for decisions of various levels of management. "

At the same time, the Longbai Group deployed and applied artificial intelligence technology to the company's intelligent transformation around the two levels of production technology and the company's operation and management of artificial intelligence, which has become another highlight of the company's intelligent transformation. Qi Manfu introduced: "During the construction of intelligent factories, we innovatively applying for production technology artificial intelligence technology and management artificial intelligence technology not only optimize titanium pink powder production technology, but also provide data decision support for corporate managers and decision makers."

Around the chloride titanium pink powder process, Longbai Group has developed a series of intelligent control system models for the core process of chloride, oxidation, boiler, and post -treatment, and realizes the online optimization and control of the production process. For example, the company develops an oxide reactor reaction control system model. DCS operators only need to set the target value, and the system can automatically adjust the process parameters such as the amount of feed, fan speed to optimize the production process. "At the level of business management, we build a private cloud platform, deploy all the systems in the cloud, build a big data resource pool of the enterprise, and integrate the data of sales, inventory, goods, finance, personnel and other data through FineReport data decision platforms; develop data The theme analysis reports of decision -making analysis form a decision -making analysis module such as sales, commodities, inventory, customers, finance, and profit analysis, and provide multi -dimensional and clear data decision support for corporate managers and decision makers. "Qi Manfu said.

Establish a full life cycle green cycle system

Create environmental protection benchmarks in titanium white powder industry

Unmanned production workshop, full -process automation, comprehensive dynamic monitoring, raw material gas recycling ... The construction of smart factories has reduced a lot of human and material resources, real -time dispatching, cleaning production, and multi -level production process of production process, and multi -level levels Safety monitoring and closed -loop management. At present, based on the key technologies of high -end titanium pink production of chloride, Longbai Group has built the largest high -end high -end chloride titanium pink powder production line with a production capacity of 660,000 tons/year. This production line not only greatly reduces waste residue discharge, but also has a significant energy saving effect.

In order to further achieve safety production, the full system of chloride titanium pink intelligent factory can be automated controlled by the full system, and the materials can be directly distributed to the production site through the warehouse without manual intervention; relying on the big data resource pool, each production link successfully achieves intelligent control and control, which is great Save manpower and material resources.

Some harmful raw materials in the chloride titanium pink production line can cause certain pollution. In this regard, the Longbai Group uses intelligent equipment to realize the recycling of pine gas cycles of raw materials and reduce the amount of harmful raw materials. Qi Manfu said that around the concept of green production, Longbai Group built a green circulation system in the full life cycle of titanium pink products, and has embarked on a unique green and high -quality development road. The construction of chloride titanium white powder intelligent factories also make Longbai Group an environmentally friendly benchmark enterprise in my country's titanium white powder industry.

Longbai Group stated that in the future, the company will focus on digital transformation, carry out the construction of equipment health management and fault diagnosis systems, and achieve closed -loop management from failure diagnosis to equipment status to improve the comprehensive efficiency of equipment; continue to improve the data decision management platform, improve data collection of data collection Deep and breadth; develop more data decision models, assist daily production and management management, further play the role of industry benchmarks, and promote the development of upstream and downstream enterprises upstream and downstream of the industry chain to achieve refined, green, and intelligent development.

- END -

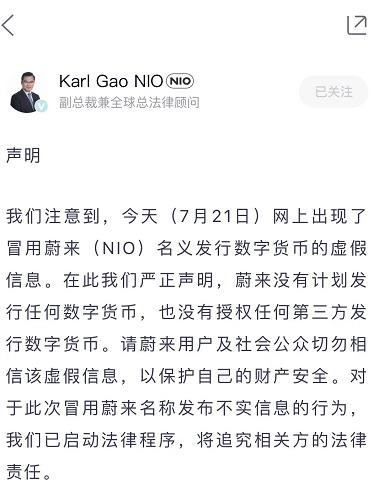

Send "Weilai Coin"?Weilai executives rumor: fake information

Zhongxin Jingwei, July 21st. On the 21st, the Weilai executives will be rumored to...

66 yuan Moutai Ice Cream purchased for 240 yuan?Someone really buy ox ice cream?

Recently, Moutai's cross -border product ice cream is undoubtedly very popular in ...