Important progress has been made in the research of low oxygen rare earth steel

Author:Guangming Daily client Time:2022.09.13

Recently, Li Dianzhong, a researcher team of the National Research Center of the National Research Center of the Institute of Metal Research of the Institute of Metal of the Chinese Academy of Sciences, prepares a superior and stable low oxygen rare earth steel.

The electronic structure of rare earth elements is unique and has excellent physical and chemical characteristics such as magnetic, light, and electrical. Adding trace of rare earth can significantly improve the tough plasticity, wear resistance, heat resistance, and corrosion resistance of steel. However, rare earth steel encountered two major problems in industrial applications and the unstable problems of steel and the performance of steel.

Through more than ten years of mechanism research and industrial experiments, the research team of Li Dianzhong was inspired by the new mechanism of the preliminary oxygen bias, and the root cause of the problem of fluctuations in rare earth steel and the problem of pouring the mouth is oxygen content. By reducing the oxygen content in the steel and rare earth metals, they combined with experiments, computing, and representation revealing the key mechanism of rare earth in the steel, controlling the solid solution of mixed objects and rare earth, and preparing superior and stable low oxygen rare earth steel.

Studies have also found that not only the oxygen content in the steel fluid affects the performance of rare earth steel, but the oxygen content in rare earth metals also has a very important impact on the performance of rare earth steel. When preparation of rare earth metal electrolytic preparation, large -sized rare earth oxides are easily formed and added to the steel fluid with rare earth metals, causing rare earth steel performance to fluctuate and respond to refractory materials.

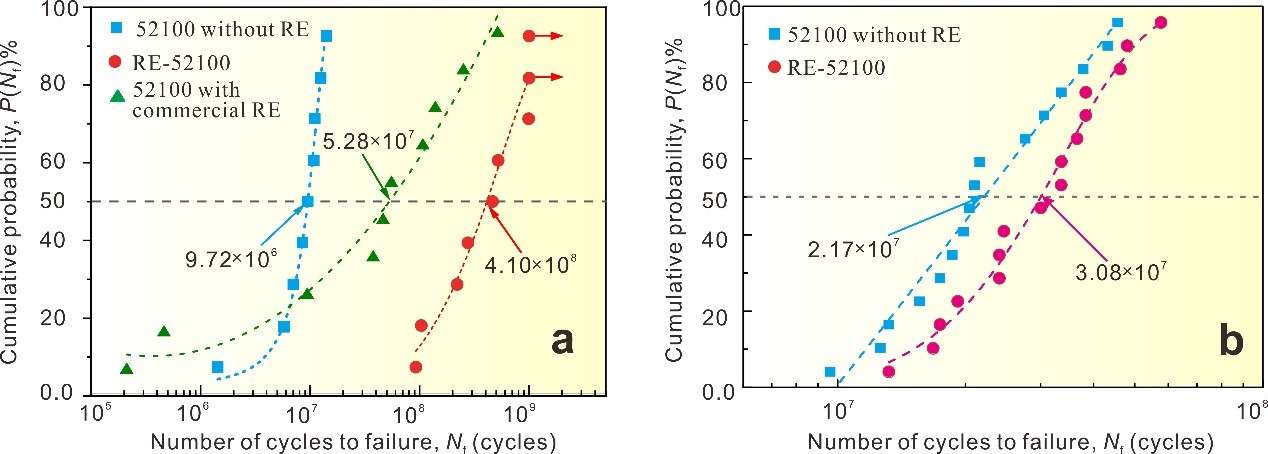

Based on the above discovery, researchers have further developed the "dual hypoxia rare earth steel" technology, that is, the control technology of steel liquid hypoxic and rare earth metal hypoxia, which effectively solves the bottleneck problem in the application of rare earth steel industry. After being applied in the high -purity GCR15 bearing steel, compared with the bearing steel without rare earth, the rare earth bearing steel ± 800MPa's fatigue life increased by 40 times, and the 40%increased rolling fatigue life under the contact stress of 4.2GPa, and added add The existing commercial rare earth metal (oxygen content in rare earth metals is 270 ppm) has a significant fluctuation of the fatigue life of samples.

Rare earth bearing steel and bearing steel without rare earth, comparative fatigue and rolling contact fatigue life of bearing steel with commercial rare earth

The research of the researcher team of Li Dianzhong revealed the root cause of the performance fluctuations of rare earth steel. It is found that only the rare earth can stabilize the effect of deep purification steel in the steel under the conditions of low oxygen conditions, refine the change of miscellaneous objects, and strong micro -alloy. Ten steel only needs to add more than a hundred grams of light rare earth. It can significantly improve the performance of steel under the condition that the cost is basically not increased and the process process is basically not changed. The quality of Youte Steel is of great significance. (Chen Jian, all media reporter of Guangming Daily)

- END -

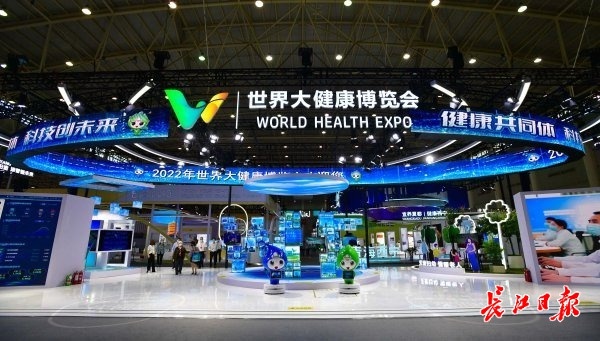

The on -site contract was signed by 44.375 billion.

The Yangtze River Daily Big Wuhan Client August 5th News On the morning of August ...

North America Observation 丨 Federal Reserve Eagle Signal detonation of the stock market Daoxing more than a thousand points

On August 26 local time, the Federal Reserve President Powell said at the Jackson ...